Light-emitting diode epitaxial wafer, manufacturing method thereof, light-emitting diode chip manufacturing method, and substrate recycling method

A technology of light-emitting diodes and epitaxial wafers, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., to achieve the effects of reducing environmental pollution, reducing costs, and small lattice mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

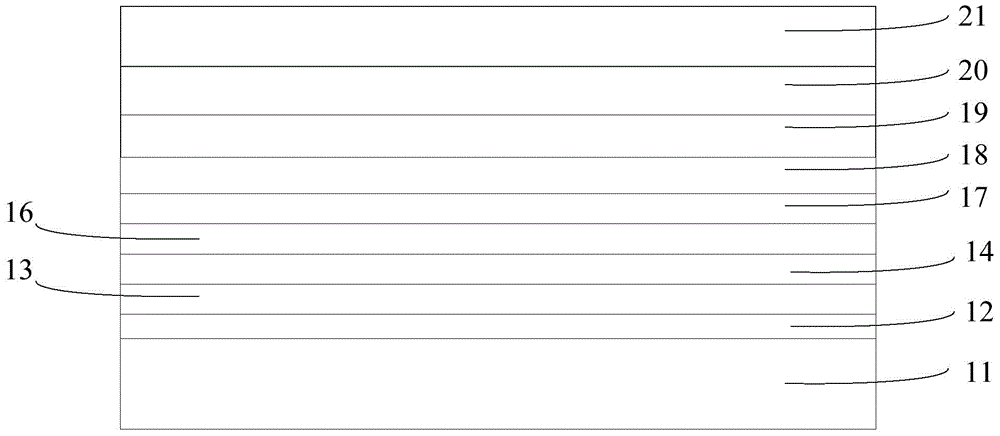

[0054] An embodiment of the present invention provides a light emitting diode epitaxial wafer, see figure 1 , the light emitting diode (Light Emiting Diode, LED for short) epitaxial wafer includes a GaAs substrate 11 and a first epitaxial layer grown on the GaAs substrate 11 .

[0055] Wherein, the first epitaxial layer includes an N-type GaAs buffer layer 12 on the GaAs substrate 11, a first N-type Ga X In 1-X P layer 13 , N-type GaAs layer 14 , N-type AlAs sacrificial layer 16 , N-type GaInP etch stop layer 17 , N-type GaAs ohmic contact layer 18 , N-type AlInP layer 19 , quantum well layer 20 , and P-type layer 21 . 0.47<X<0.51.

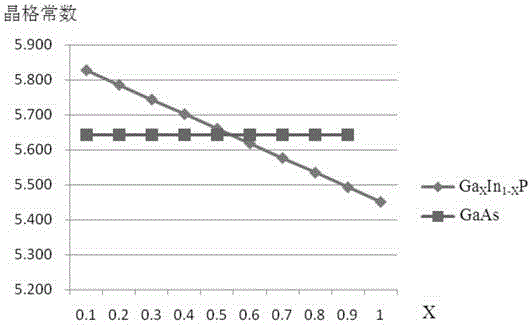

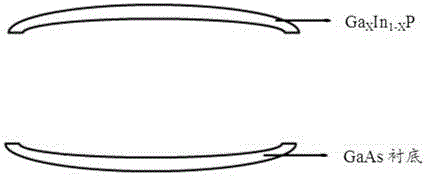

[0056] Among them, the first N-type Ga X In 1-X The lattice constants of the P layer, the N-type GaAs layer, and the N-type AlAs sacrificial layer are similar to those of the GaAs substrate and the AlGaInP LED epitaxial layer materials, and the lattice mismatch is small. figure 2 shows the Ga X In 1-X Lattice constants of P and GaAs. When...

Embodiment 2

[0063] The embodiment of the present invention provides a method for preparing an epitaxial wafer of a light emitting diode, which is suitable for preparing an epitaxial wafer of an AlGaInP LED. see Figure 5 , the method includes:

[0064] Step 201, providing a GaAs substrate.

[0065] Step 202, growing a first epitaxial layer on the GaAs substrate to obtain an LED epitaxial wafer.

[0066] Wherein, the first epitaxial layer includes an N-type GaAs buffer layer, a first N-type Ga X In 1-X P layer, N type GaAs layer, N type AlAs sacrificial layer, N type GaInP etch stop layer, N type GaAs ohmic contact layer, N type AlInP layer, quantum well layer, and P type layer. 0.47<X<0.51.

[0067] Optionally, the first N-type Ga X In 1-X The growth conditions of the P layer include growth temperature of 640-660 degrees, TMGa flow of 40-50sccm, TMIn flow of 800-850sccm, PH3 flow of 900-1100sccm, thickness of 100-300nm, doping concentration of 1e-18~ 5e-18, the lattice mismatch is...

Embodiment 3

[0075] The embodiment of the present invention provides a method for preparing a light emitting diode chip, which is suitable for preparing an AlGaInP LED chip. see Figure 6 , the method includes:

[0076] Step 301, providing a first epitaxial wafer.

[0077] Wherein the structure of the first epitaxial wafer is the same as that of the LED epitaxial wafer provided in Embodiment 1, and will not be repeated here.

[0078] Step 302, bonding the first epitaxial wafer to the first substrate.

[0079] Among them, see Figure 7 , the first epitaxial layer 10 is located between the GaAs substrate 11 and the first substrate 30 .

[0080] The prepared first epitaxial wafer can be bonded to the first substrate through a metal bonding process, and the material of the first substrate can be Si, sapphire, flexible conductive polyester resin (English: Polyethylene Terephthalate, abbreviated: PET or PEIT), or copper.

[0081] Since the epitaxial layer is very thin, the first epitaxial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com