ANSYS-based duplex stainless steel and dissimilar steel welding deformation prediction method

A duplex stainless steel, welding deformation technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. The effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

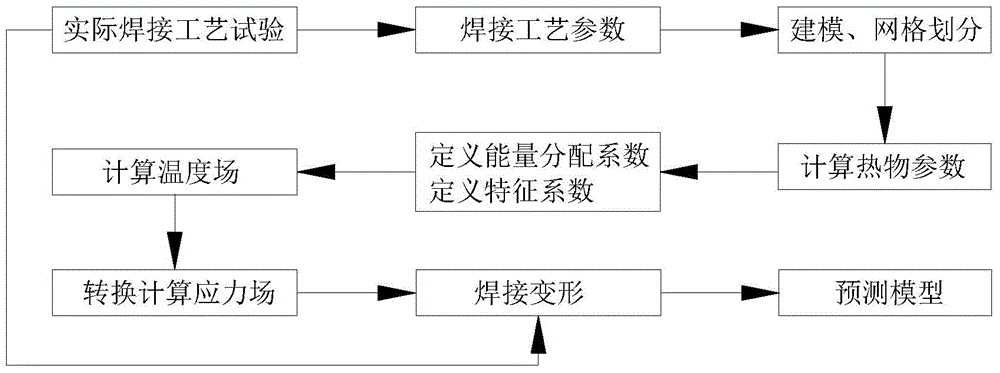

[0042] An ANSYS-based prediction method for welding deformation of duplex stainless steel and dissimilar steel, including the following 6 steps:

[0043] (1) Determine the welding process parameters

[0044] The welding process parameters are determined through the welding process test: the size of the process sample is 450×150×δ20mm, the welding method is molten inert gas shielded welding (MIG welding), the welding material ER2594 welding wire (φ1.2), no preheating is required during welding And after heat, strictly control the layer temperature to less than 150 ℃, and control the welding line energy between 10 ~ 15KJ / cm, the shielding gas is 99.99% argon, and the back is used as a ceramic liner. A total of 5 layers and 9 passes were welded during the welding test, and the process parameters of each layer and each pass are shown in Table 1 below.

[0045] Table 1 Welding process parameters

[0046]

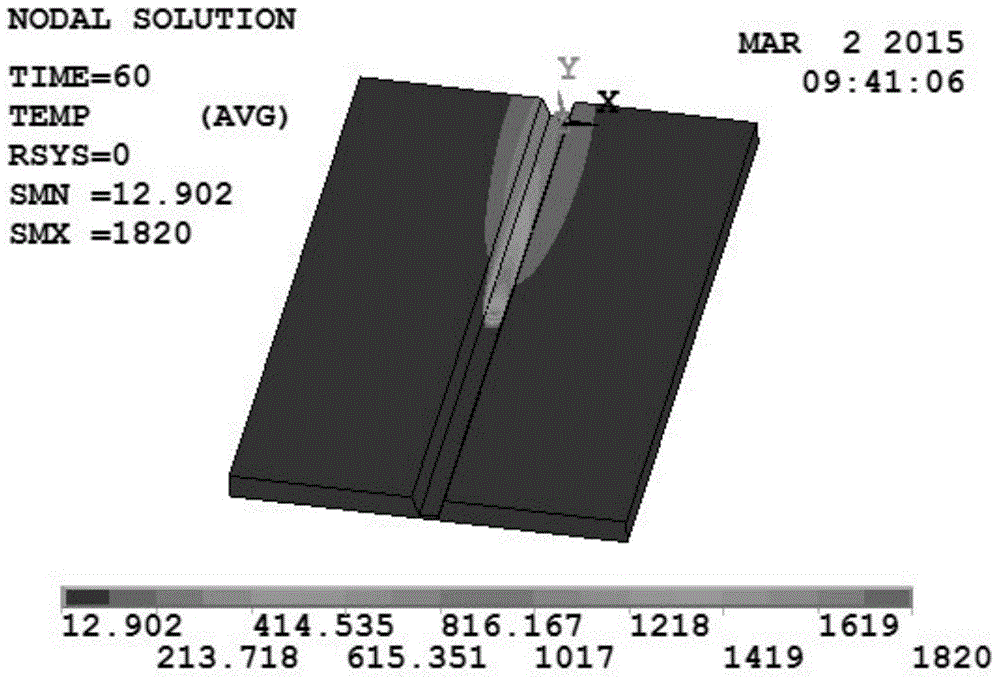

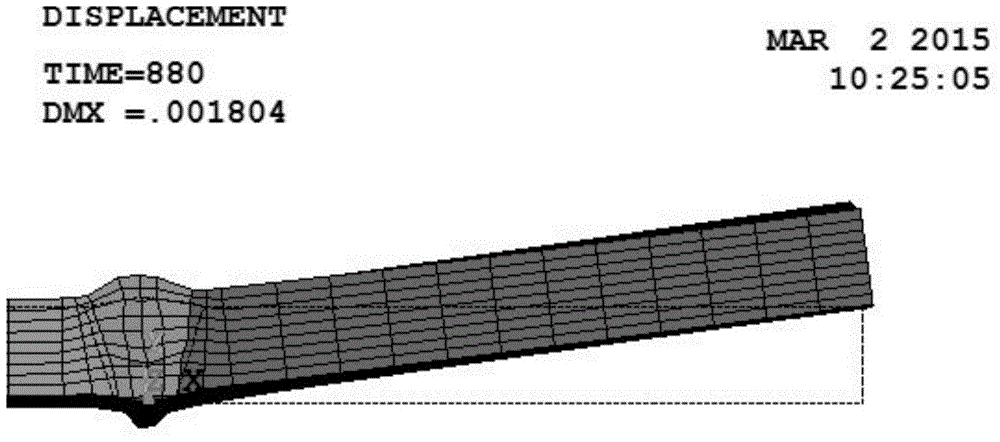

[0047] (2) Establish finite element model and perform grid division

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com