Capacitive touch screen and preparation method

A technology of capacitive touch screen and sensing electrode, which is applied in the direction of electrical digital data processing, instrumentation, data processing input/output process, etc., can solve the problems of long cycle, many equipments, and increasing process difficulty, and achieve overall thickness reduction and simplification Etching process, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

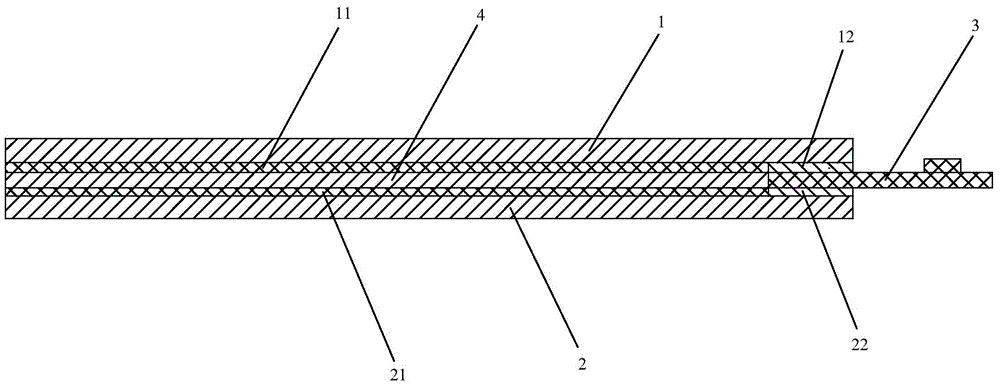

[0030] The driving electrode layer 21 in the present embodiment is a graphene sensing electrode layer, the film layer 2 is a PET film layer, and the thickness of the panel layer 1 is 0.5mm; the thickness of the film layer 2 is 0.1mm; the thickness of the transparent insulating adhesive layer 4 is 0.05mm.

Embodiment 2

[0032] The driving electrode layer 21 in the present embodiment is the induction electrode layer that graphene and ITO mix, and film layer 2 is PMMA layer, and the thickness of glass panel layer 1 is 0.7mm; The thickness of film layer 2 is 0.3mm; Transparent insulating adhesive layer 4 has a thickness of 0.2mm.

[0033] In practical applications, the driving electrode layer 21 can also be a metal mesh wire sensing electrode layer or an ITO sensing electrode layer.

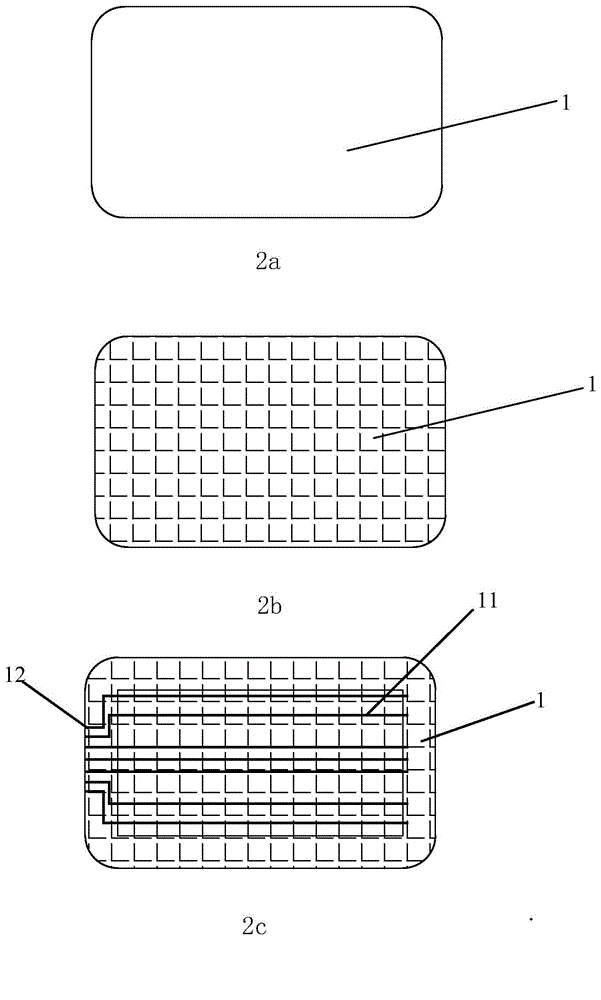

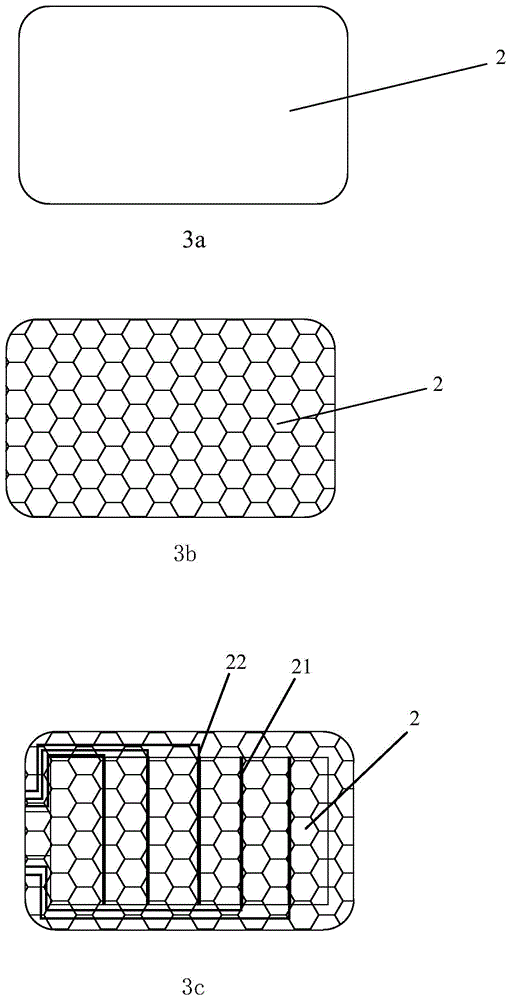

[0034] Such as figure 2 Shown, the preparation method of a kind of capacitive touch screen of the present invention, it comprises the following steps:

[0035] Sputtering the first conductive film layer on the surface of glass panel layer 1 (such as figure 2 2b in ), and at the same time generate a second conductive film layer on the surface of the film layer 2 (such as image 3 3b) in which the process vacuum during sputtering is between 0.05 and 1Pa, and the sputtering power density is between 1 and 5W / cm 2...

Embodiment 3

[0049] In this embodiment, when sputtering the first conductive film layer on the surface of the glass panel layer 1 and generating the second conductive film layer on the surface of the film layer 2, the process vacuum is 0.6Pa, and the sputtering power density is 4W / cm2; After the first conductive film layer is sputtered on the surface of the glass panel layer 1, and after the second conductive film layer is sputtered on the surface of the thin film layer 2 and before the laser etching is carried out to the first conductive film and the second conductive film, also The method comprises the step of printing a silver paste layer on the first conductive film and the second conductive film, so that the channel resistance of the touch screen meets the requirement.

[0050] When the first conductive film layer is laser etched to form the sensing electrode layer 11, and the second conductive film layer is laser etched to form the driving electrode layer 21, the laser power is 13W; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com