Plunger-type double-passage different-direction synchronous joint control check valve for double-layer continuous oil pipe

A double-layer tubing, double-channel technology, applied in wellbore/well valve devices, wellbore/well components, earth-moving drilling, etc., can solve problems such as damage and fracture of double-layer coiled tubing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

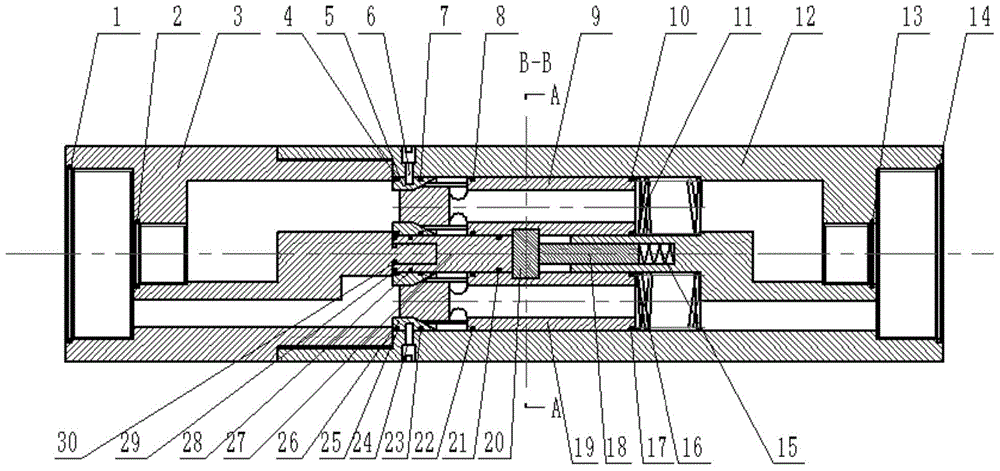

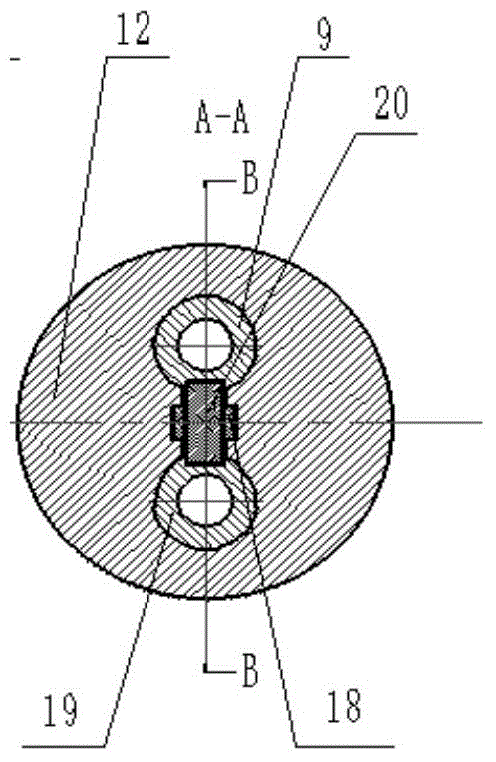

[0051] Such as Figure 1-6 As shown, the double-layer coiled tubing uses a plunger-type dual-channel different-direction synchronous joint-controlled single-flow valve, which is arranged between the double-layer oil pipe pipelines, including a left valve body 3, a right valve body 12, an inner channel piston 9, and an inner channel piston 9. Channel piston seat 5, outer channel piston 19, outer channel piston seat 26, long pin 20, cross plunger 27, slide block 18, inner channel piston return spring 11, outer channel piston return spring 16 and slide block return spring 15.

[0052] Such as Figure 3-4 As shown, the left valve body 3 has a cylindrical structure, and the inner wall at one end is finished with a double-layer box for connecting the inner and outer coiled tubing bodies, that is, the double-layer internal thread; the outer wall at the other end is finished with a double-layer box. In order to connect the male buckle of the right valve body 12, that is, the external...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com