Embedded type phase-change energy storage microcapsule with enhanced heat conduction and preparation method of microcapsule

A technology of phase change energy storage and microcapsules, which is applied in the direction of microcapsule preparation, preparation of microspheres, chemical instruments and methods, etc., can solve the problems of preparation methods that are harmful to health and environmental protection, thermal conductivity and stability of phase change energy storage microcapsules. Advanced problems, to achieve good heat conduction, improve heat conduction performance, structure and performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

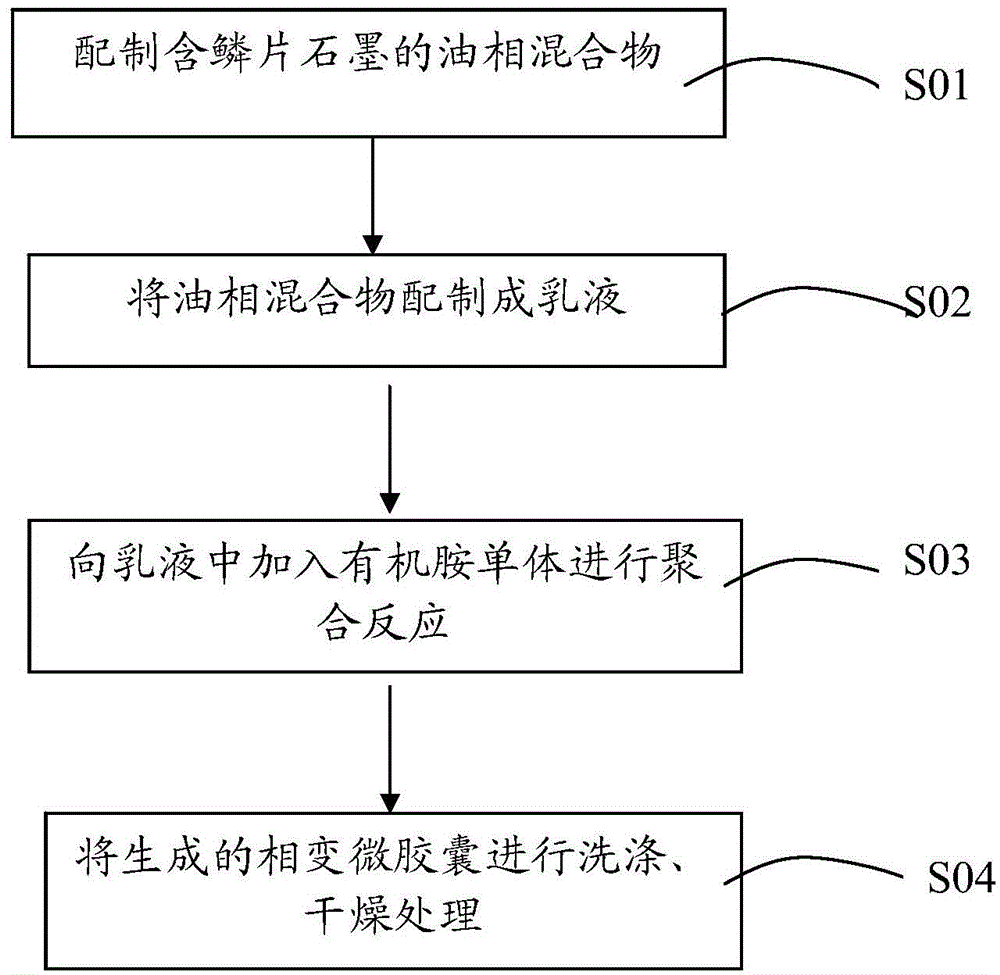

[0031] Correspondingly, the embodiment of the present invention also provides a preparation method of the phase-change energy storage microcapsules of the above-mentioned invention embodiment. The preparation method of the phase change energy storage microcapsules of the embodiment of the present invention is as follows: image 3 As shown, it includes the following steps:

[0032] Step S01. Preparation of an oil phase mixture containing flake graphite: mixing the oil-soluble phase change material, diisocyanate monomer and flake graphite with a melting point of 10-70°C at a temperature above the melting point of the oil-soluble phase change material, Obtain an oil phase mixture;

[0033] Step S02. The oil phase mixture is formulated into an emulsion: the oil phase mixture is mixed with an aqueous solution of an anionic emulsifier and then emulsified at a temperature above the melting point of the oil-soluble phase change material to obtain an emulsion;

[0034] Step S03. Adding organ...

Embodiment 1

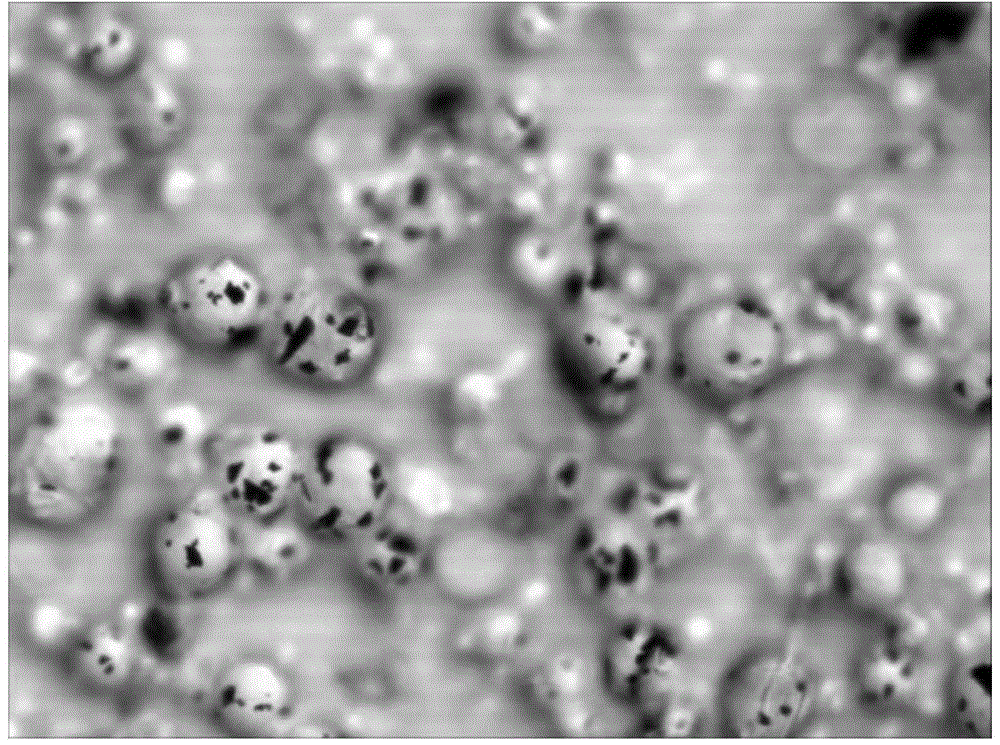

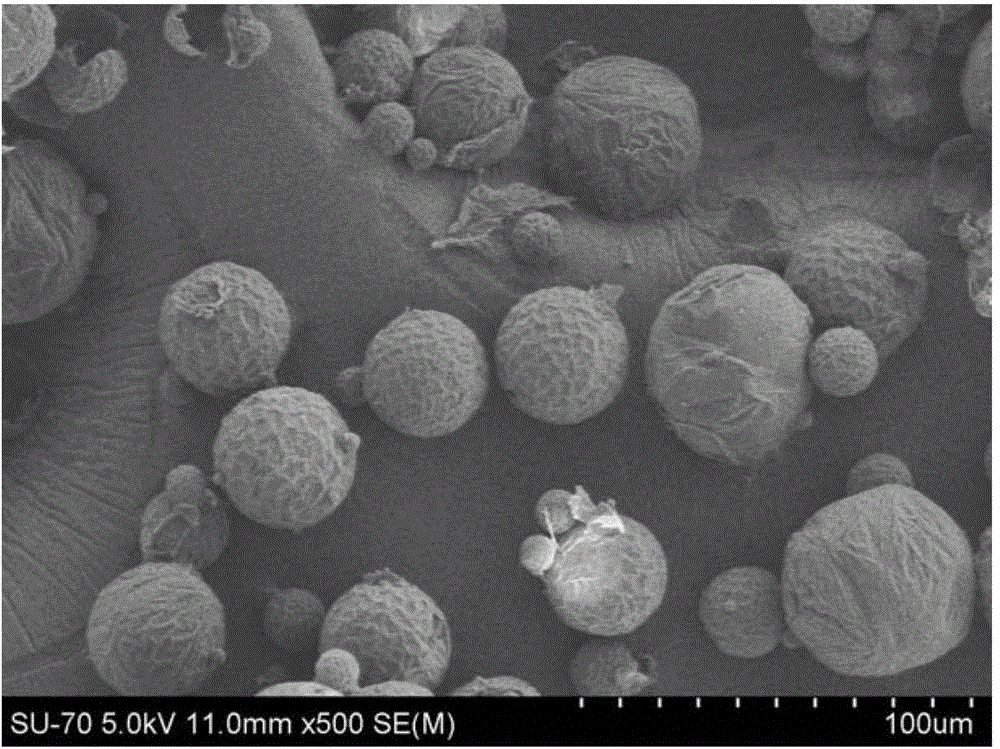

[0053] A phase change energy storage microcapsule and a preparation method thereof. The phase change energy storage microcapsule has a structure such as figure 1 , 2 As shown, it includes a microcapsule shell and a phase change composite core material arranged in the microcapsule shell. Wherein, the phase change composite core material includes an oil-soluble organic phase change material with a melting point of 10-70°C and flake graphite doped in the oil-soluble organic phase change material; the microcapsule shell is doped with flakes Graphite polyurea compound.

[0054] The preparation method of phase change energy storage microcapsules is as follows:

[0055] S11 first add 7g of phase-change energy storage wax with melting point of 28℃, 3g of isophorone diisocyanate and 0.1g of 800 mesh flake graphite in a 50ml beaker, heat to 40-60℃, magnetically stir until it is evenly mixed, and ultrasonically disperse for 30 Minutes, as the oil phase for standby.

[0056] S12 Add 1.5g of st...

Embodiment 2

[0061] A phase change energy storage microcapsule and a preparation method thereof. The phase change energy storage microcapsule has a structure such as figure 1 , 2 As shown, the structure is the same as the phase change energy storage microcapsule in Example 1.

[0062] The preparation method of phase change energy storage microcapsules is as follows:

[0063] S21 firstly add 7g of phase change energy storage wax with melting point of 28℃, 3g of toluene diisocyanate and 0.3g of 800 mesh flake graphite in a 50ml beaker. The temperature is raised to 40-60℃, magnetically stirred until it is uniformly mixed, and ultrasonic dispersion is used for 30 minutes. The oil phase is reserved.

[0064] S22 Add 1.5g of sodium dodecylbenzene sulfonate and 50ml of deionized water in a 100ml beaker, mix well, add the oil phase mixture of step S21, and disperse at 5000r / min for 20 minutes at 50°C to obtain a water packet Oil emulsion.

[0065] S23 transfer the emulsion of step S22 into a 250ml three-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com