Novel high temperature-resistant epoxy resin structure adhesive and preparation method thereof

A kind of epoxy resin, high temperature resistance technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of high temperature occasions, high temperature resistance, limited application range, etc., to strengthen the adhesion, High heat resistance and improved wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A new type of high temperature resistant epoxy resin structural adhesive, which includes component A and component B,

[0030] Component A comprises the following components by weight:

[0031] Bisphenol S type epoxy resin 60g,

[0032] Active diluent 12g,

[0033] Novolak epoxy resin 28g;

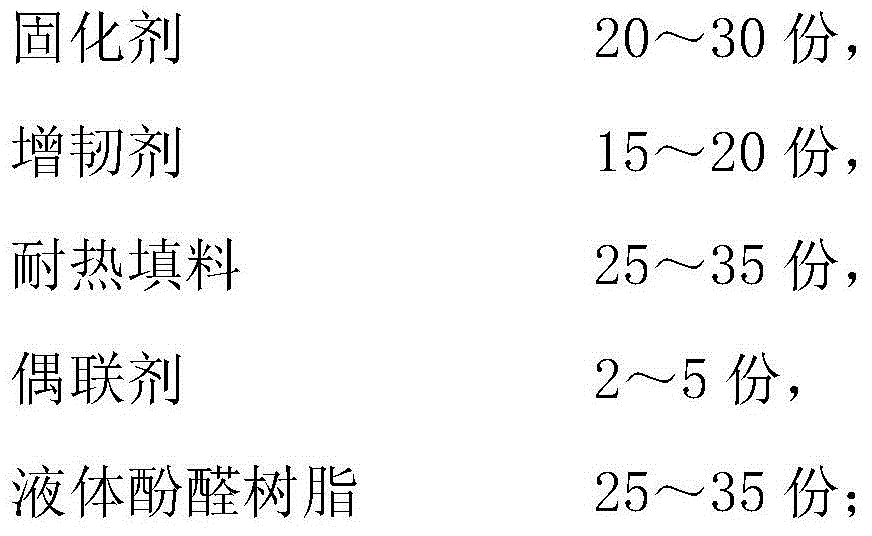

[0034] Component B comprises the following components by weight:

[0035]

[0036] The mass ratio of component A and component B is 1:1.

[0037] Its preparation method comprises the following steps:

[0038] (1) Dry the heat-resistant filler, add it to the acetone solution of the coupling agent, disperse and stir it with ultrasonic waves for 40 minutes, and dry it after removing the solvent to obtain the modified heat-resistant filler;

[0039] (2) Add bisphenol S-type epoxy resin, reactive diluent, and novolac epoxy resin into the mixer, and vacuumize and stir for 40 minutes to obtain component A;

[0040] (3) Add the modified heat-resistant filler, curing agent, tougheni...

Embodiment 2

[0043] A new type of high temperature resistant epoxy resin structural adhesive, which includes component A and component B,

[0044] Component A comprises the following components by weight:

[0045] Bisphenol S type epoxy resin 75g,

[0046] Active diluent 5g,

[0047] Novolak epoxy resin 20g;

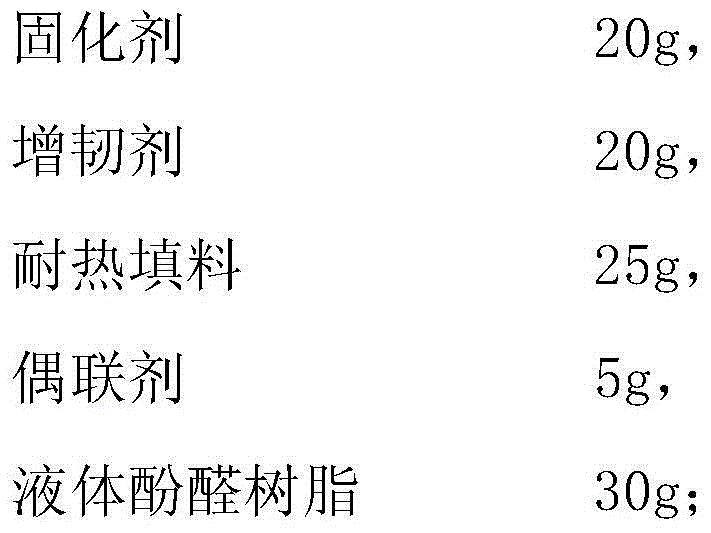

[0048] Component B comprises the following components by weight:

[0049]

[0050] The mass ratio of component A and component B is 1:1.

[0051] Its preparation method comprises the following steps:

[0052] (1) Dry the heat-resistant filler, add it to the acetone solution of the coupling agent, disperse and stir it with ultrasonic waves for 40 minutes, and dry it after removing the solvent to obtain the modified heat-resistant filler;

[0053] (2) Add bisphenol S-type epoxy resin, reactive diluent, and novolac epoxy resin into the mixer, and vacuumize and stir for 40 minutes to obtain component A;

[0054] (3) Add the modified heat-resistant filler, curing agent, toughenin...

Embodiment 3

[0057] A new type of high temperature resistant epoxy resin structural adhesive, which includes component A and component B,

[0058] Component A comprises the following components by weight:

[0059] Bisphenol S type epoxy resin 64g,

[0060] Active diluent 6g,

[0061] Novolak epoxy resin 30g;

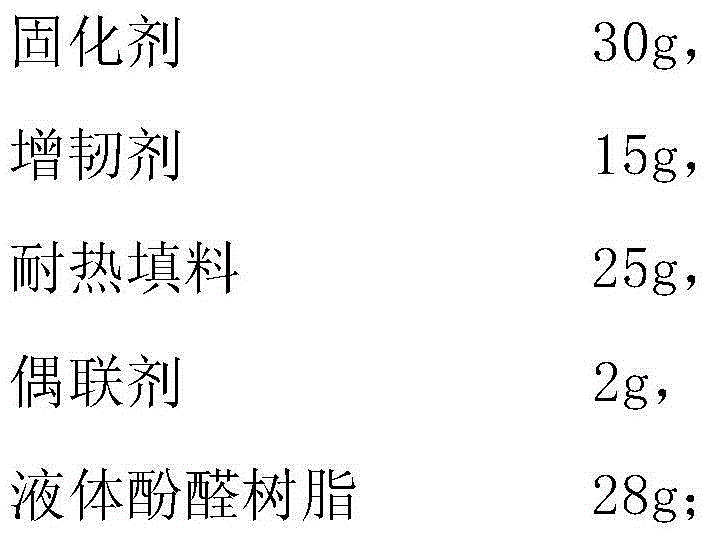

[0062] Component B comprises the following components by weight:

[0063]

[0064] The mass ratio of component A and component B is 1:1.

[0065] Its preparation method comprises the following steps:

[0066] (1) Dry the heat-resistant filler, add it to the acetone solution of the coupling agent, disperse and stir it with ultrasonic waves for 40 minutes, and dry it after removing the solvent to obtain the modified heat-resistant filler;

[0067] (2) Add bisphenol S-type epoxy resin, reactive diluent, and novolac epoxy resin into the mixer, and vacuumize and stir for 40 minutes to obtain component A;

[0068] (3) Add the modified heat-resistant filler, curing agent, toughenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com