Halogen-free hyperbranched polymer and modified polypropylene containing same

A technology of hyperbranched polymer and polypropylene, applied in the field of polypropylene modified materials, can solve the problems of dependence on imports and large gaps in polypropylene plastics, and achieve the effects of reducing energy consumption, improving the appearance of products, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of modified polypropylene can be any method known in the art. For example, the modified polypropylene of the present invention can be prepared by mechanically mixing the various components. Specifically, commonly used mixers such as kneaders, single-screw extruders, twin-screw extruders, multi-screw extruders, and the like can be used. Preferably, a modified polypropylene containing a halogen-free hyperbranched polymer is obtained by blending and granulating in a twin-screw extruder at 150-280°C, and the weight ratio of the halogen-free hyperbranched polymer to polypropylene is (0.1 ~20): 100, preferably, the weight ratio is (1~4): 100. .

[0033] The modified polypropylene prepared above can be processed into extrusion molding, blow molding, injection molding or sheet molding. Although not intended to be limiting, injection molding is preferred.

[0034]The modified polypropylene of the present invention can further add any commercially avail...

Embodiment 1

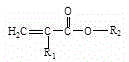

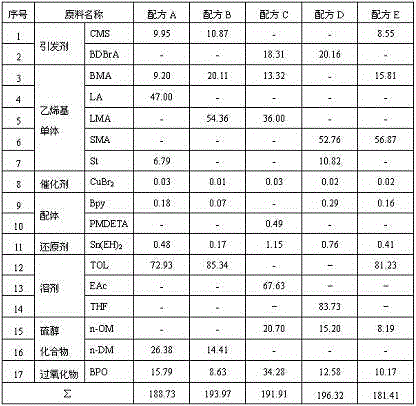

[0035] Embodiment 1, synthesize hyperbranched polymer and carry out end group modification preparation required halogen-free hyperbranched polymer:

[0036] First exhaust the air in the reaction system, pass inert gas, add the initiator halogenated ester or hydrocarbon and solvent into the reaction device according to the amount, and then put the catalyst, vinyl monomer, reducing agent and ligand into the reaction in sequence Kettle, stirring the reaction at 65°C for 11h, using 1 H-NMR nuclear magnetic resonance detects the conversion rate of the double bond, and the conversion rate reaches more than 80%, which is the end point of the reaction. Then add thiol compound, react at 30-40° C. for 15 hours, add peroxide to remove excess thiol compound, and obtain halogen-free hyperbranched polymer after precipitation.

[0037] According to the above method, each component listed in the following table and its dosage (the values in the table are parts by weight) were weighed and m...

Embodiment 2

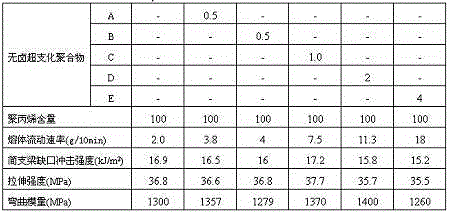

[0057] Example 2, preparing modified polypropylene containing halogen-free hyperbranched polymer by blending and extruding and performing injection molding processing:

[0058] The above-mentioned halogen-free hyperbranched polymer and polypropylene are blended and granulated through a twin-screw extruder according to the ratio in the table below to obtain modified polypropylene. 220~235℃, 215~220℃ in the fourth zone. After the modified polypropylene is injection-molded into a test sample, the sample test is placed in the sample room for 24 hours. The temperature of the sample room is kept at 23°C and the relative humidity is at 50%.

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com