Novel desulfurization waste water treatment method

A wastewater treatment and new desulfurization technology, which is applied in the direction of gaseous effluent wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problems of heavy metals difficult to meet standards, large amount of sludge, and high cost. , to reduce treatment costs, improve effluent water quality, and avoid system blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

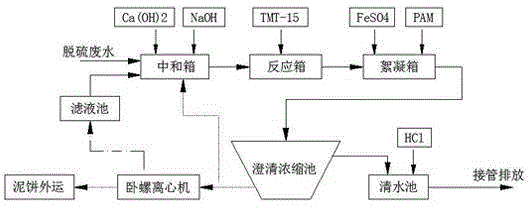

[0024] figure 1 Shows the existing treatment process of desulfurization wastewater, the wastewater is treated through neutralization, reaction, flocculation, combined with figure 1 and figure 2 To further illustrate the present invention, a new type of desulfurization wastewater treatment process includes a secondary reaction precipitation process. The process flow is as follows: the wastewater treated by the gypsum cyclone and the vacuum belt dehydrator is collected into the adjustment tank, and after stirring and balancing; The lift pump is pumped from the regulating tank into the first reaction tank of the primary reaction sedimentation tank, and NaOH is added to the wastewater in the first reaction tank to adjust the pH to 10~13, and the waste water overflows into the second reaction tank through the first reaction tank, Lime milk is added to the second reaction tank, and the waste water overflows into the high-load sedimentation tank through the second reaction tank for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com