Reaction transfer frame in automobile lighting lamp

A technology of transfer frame and lighting lamp, which is applied in the field of reaction transfer frame in automotive lighting lamps, which can solve the problems of no effective curing time and curing efficiency, unfavorable production line production operation, production line congestion and suspension, etc., to save manpower, material resources and curing time , to avoid the effect of sudden pause

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

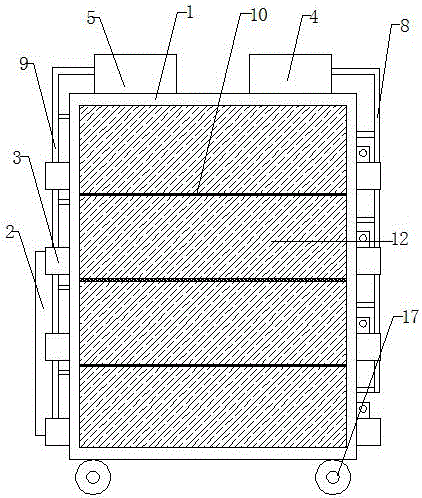

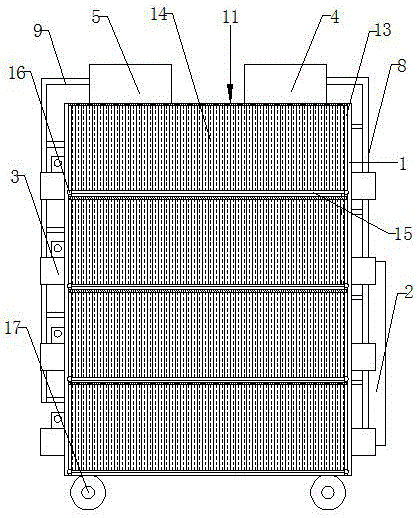

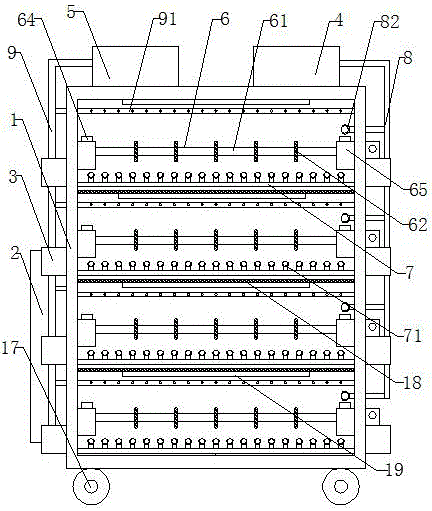

[0023] Refer to attached Figure 1-4 The reaction transfer frame shown in a car lighting lamp includes a rectangular parallelepiped transfer frame body 1 with openings at both front and rear ends. The transfer frame body 1 is made of tempered glass, and the transparent shell of tempered glass is convenient for observing the internal reaction conditions. Abnormal problems that occur can be remedied in time, and the toughened glass also has the effect of preventing cracks and dust. The bottom of the transfer frame body 1 is also provided with universal wheels 17, which are set to realize the transfer frame The body 1 is free to move, and four layers of mobile storage layers 6 are arranged in the transfer frame body 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com