End surface grinding device for fiber connector

A technology for optical fiber connectors and grinding devices, which is applied in the direction of grinding devices, grinding drive devices, grinding machine tools, etc. It can solve the problems of different removal of end-face materials and affect the grinding effect of the end-face of optical fiber connectors, and achieve the effect of improving coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below with reference to the accompanying drawings.

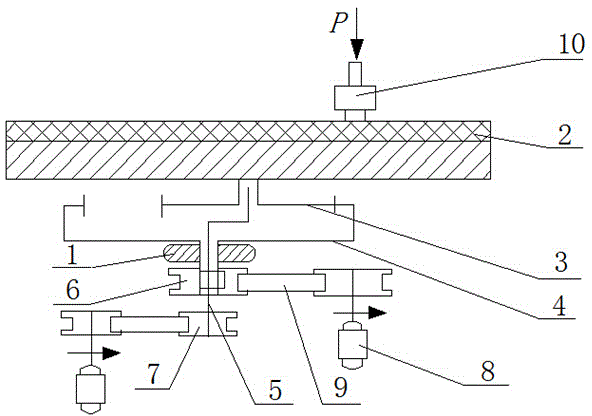

[0013] Such as figure 1 As shown, a fiber optic connector end face grinding device includes a grinding disc 2 and a frame 1, the grinding disc 2 is arranged on the upper part of the frame 1, and a planetary gear 3 and a ring gear are also arranged between the grinding disc 2 and the frame 1 4. A tie rod 5 connecting the planetary gear 3 and the ring gear 4 runs through the middle of the frame 1, and a first pulley 6 and a second pulley 7 are arranged under the frame 1. The first pulley 6 is connected to the gear ring, the second pulley 7 is sleeved on the tie rod 5 , and the first pulley 6 and the second pulley 7 are respectively connected to a motor 8 through a timing belt 9 .

[0014] In this embodiment, the surface of the grinding disc 2 is a thin film with abrasive materials, and its thickness is 70 μm.

[0015] During the grinding process, the end face of the opti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com