Large tube base groove machining process with special structure

A technology of groove processing and special structure, which is applied in the processing technology field of the groove of large pipe seat, can solve the problems that the location of the location is affected by the welding seam, the processing accuracy is difficult to control, and the positioning of the pipe row is difficult, so as to solve the problems that cannot be processed, processed The effect of high precision and guaranteed efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

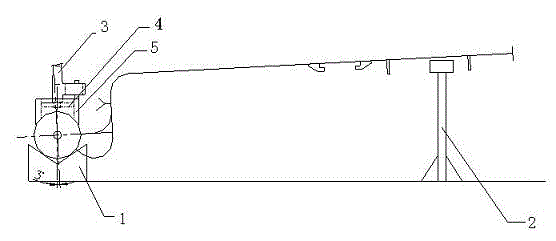

[0027] Such as figure 1 As shown, the present invention is a special structure of a large pipe socket groove processing technology, the processing technology includes the following steps:

[0028] (1) Workpiece fixation: Install two V-shaped seats on the drilling machine working platform, and firmly connect the V-shaped seats and the drilling machine working platform with bolts, put the header part on the V-shaped seat, and place the pipe row part on the saddle;

[0029] (2) Adjust the level of the workpiece: Install a threaded lifting frame at the end of the pipe row away from the header, use the lifting frame to change the height of the pipe row, and use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com