Generator charging circuit, battery isolator, charger, inverter and carrier

A charging circuit and generator technology, which is applied in the electronic field, can solve problems such as bad charging of secondary batteries, different voltages of secondary batteries, and large power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

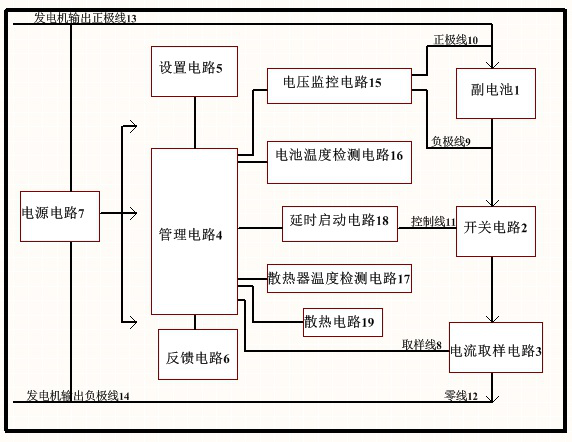

[0096] A generator charging circuit:

[0097] figure 1 It is a structural diagram of the generator charging circuit of the present invention.

[0098] The charging main circuit according to the current direction: generator output positive pole line 13-secondary battery 1-switching circuit 2-current sampling circuit 3-generator output negative pole line 14.

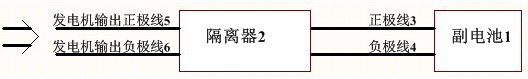

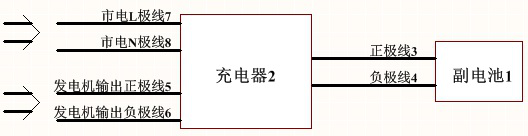

[0099] According to the different positions of the auxiliary battery 1, the switch circuit 2, and the current sampling circuit 3, there are 5 other layout modes for the charging main circuit. Figure 7 It is another three structural diagrams of the charging main circuit of the present invention. These layouts can realize the PWM mode charging current limit of the sub-battery 1, but the corresponding circuit can be slightly adjusted. figure 1 The layout is just one of them.

[0100] The switch circuit 2 includes a switch tube and a drive circuit. The most commonly used switching tube is the mos field effect tube, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com