Battery negative electrode active material based on quinone structure and preparation method and application thereof

A technology of battery negative electrode and active material, applied in the field of materials, can solve the problems of low Coulombic efficiency, poor cycle performance, hidden safety hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Embodiment 1 of the present invention provides a battery negative electrode material based on a quinone structure, including a quinone compound with a quinone structure as an electrochemical redox reaction site;

[0068] Among them, the quinone compounds include any one of benzoquinone sodium salt derivatives, anthraquinone sodium salt derivatives or naphthoquinone sodium salt derivatives; benzoquinone sodium salt derivatives, anthraquinone sodium salt derivatives or naphthoquinone sodium salt derivatives Derivatives have the following groups -ONa, -SO 3 At least one of Na or -COONa.

[0069] Specifically, the structure of the benzoquinone sodium salt derivative is shown in general formula (I):

[0070]

[0071] General formula (I)

[0072] Among them, the group R 1 , R 2 , R 3 , R 4 At least one group in is -ONa, -SO 3 One of Na or -COONa, other groups include -ONa, -SO 3 Na, -COONa, -H, -CH 3 , -NH 2 、-OCH 3 , -Cl, -Br or -F in one or more.

[0073] The...

Embodiment 2

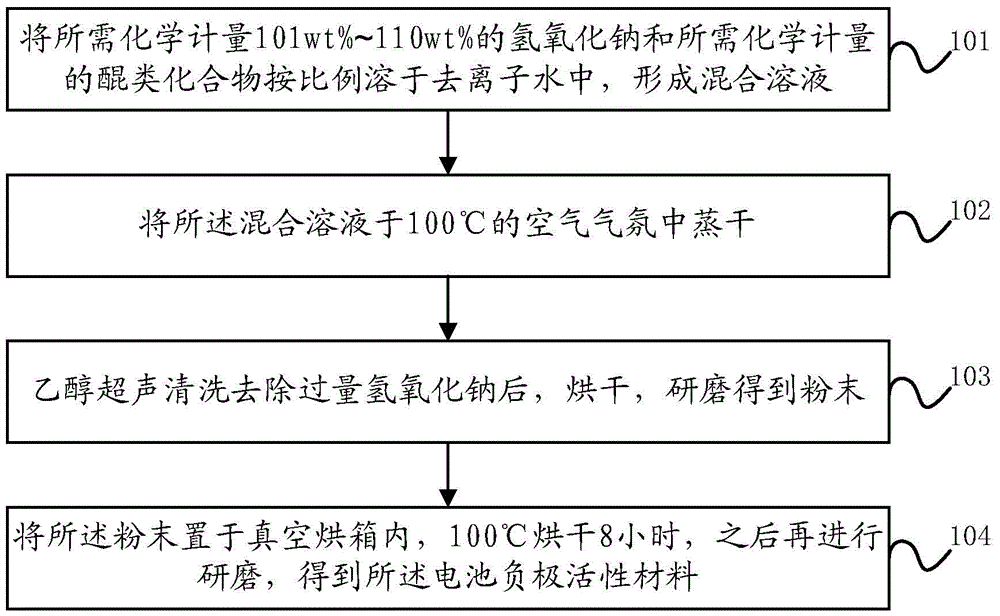

[0083] This embodiment provides a method for preparing a battery negative electrode active material based on a quinone structure, specifically an aqueous solution method, such as figure 1 shown, including:

[0084] Step 101, dissolving the required stoichiometric 101wt% to 110wt% sodium hydroxide and the required stoichiometric quinone compound in deionized water in proportion to form a mixed solution;

[0085] Wherein, the quinone compound is specifically one of hydroxyquinone compounds, carboxylic acid quinone compounds or sulfonic acid quinone compounds.

[0086] Step 102, evaporating the mixed solution to dryness in an air atmosphere at 100°C;

[0087] Step 103, after ultrasonic cleaning with ethanol to remove excess sodium hydroxide, drying and grinding to obtain powder;

[0088] In step 104, the powder is placed in a vacuum oven, dried at 100° C. for 8 hours, and then ground to obtain the negative electrode active material of the battery.

[0089] The preparation meth...

Embodiment 3

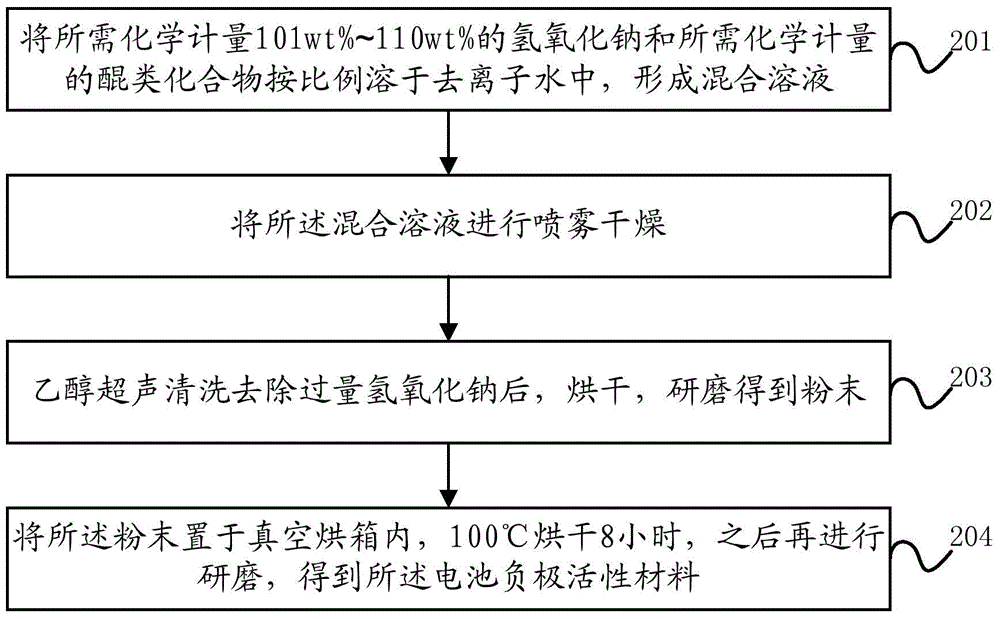

[0091] This embodiment provides a method for preparing battery negative electrode active materials based on quinone structure, specifically spray drying method, such as figure 2 shown, including:

[0092] Step 201, dissolving the required stoichiometric 101wt%-110wt% sodium hydroxide and the required stoichiometric quinone compound in deionized water in proportion to form a mixed solution;

[0093] Wherein, the quinone compound is specifically one of hydroxyquinone compounds, carboxylic acid quinone compounds or sulfonic acid quinone compounds.

[0094] Step 202, spray drying the mixed solution;

[0095] Step 203, after ultrasonic cleaning with ethanol to remove excess sodium hydroxide, drying and grinding to obtain powder;

[0096] In step 204, the powder is placed in a vacuum oven, dried at 100° C. for 8 hours, and then ground to obtain the battery negative electrode active material.

[0097]The preparation method of the negative electrode active material of the battery ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com