Energy absorbing anti-impact hydraulic support for fully-closed round roadway

A fully enclosed hydraulic support technology, which is applied in pillars/supports, mining equipment, earthwork drilling and mining, etc., can solve problems such as support body damage, traffic obstruction, and hydraulic support bending, so as to prevent instability and damage and alleviate impact Function, effect of protection from damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

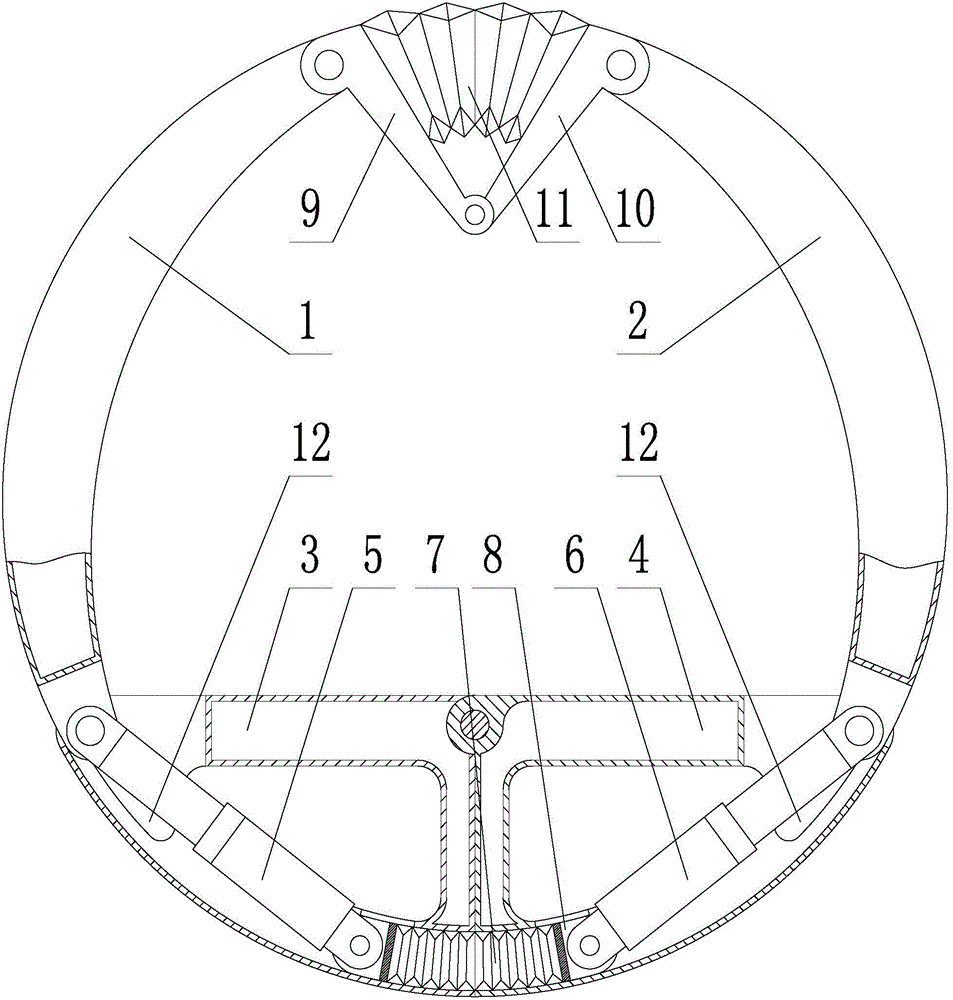

[0015] Such as figure 1 As shown, a fully enclosed circular roadway energy-absorbing and anti-scour hydraulic support includes a left beam 1, a right beam 2, a left bottom beam 3, a right bottom beam 4, a left hydraulic prop 5 and a right hydraulic prop 6. The left bottom beam 3 is located under the left side beam 1, the right bottom beam 4 is located under the right side beam 2, the left bottom beam 3 and the right bottom beam 4 are symmetrically arranged, and the left bottom beam 3 and the right bottom beam 4 are arranged at the center of symmetry. Hinged, the left bottom beam 3 and the right bottom beam 4 that are hinged together form an integral bottom beam with a half-moon structure; a slideway passing through the left and right bottom beams is provided at the bottom of the integral bottom beam, and a bottom beam is arranged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com