Manganese-bismuth-iron-phosphor permanent magnetic alloy plating solution and preparation method thereof

A technology of permanent magnet alloy and electroplating solution, applied in liquid application, application of magnetic film to substrate, etc., to achieve the effect of long standing time, good alloy stability, good plasticity and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

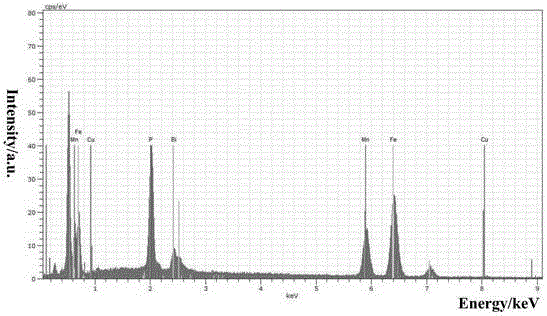

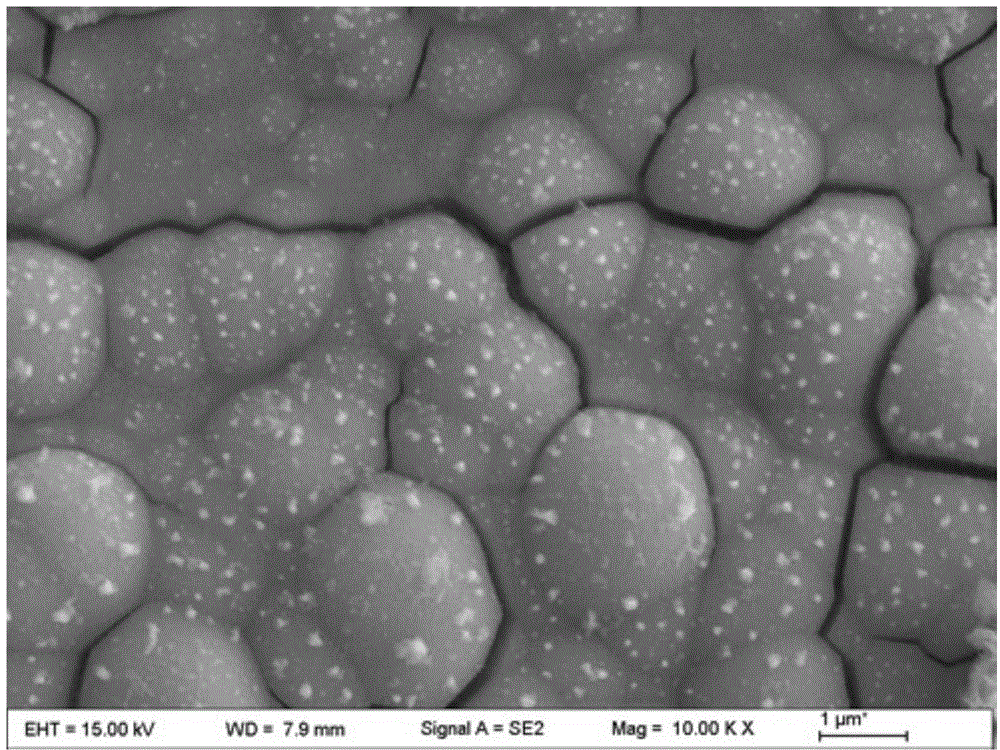

[0020] Dissolve 40g of boric acid in 0.5L of warm water, add 40g of sodium hypophosphite and 40g of sodium citrate in turn under stirring, stir thoroughly, and mix well to obtain solution A; adjust the pH of solution A with 1.0mol / L HCl 2. Add 10g of ferrous chloride, 60g of manganese chloride, 6g of bismuth chloride and 3g of ascorbic acid in turn under stirring. After fully stirring for 2 hours, add an appropriate amount of water to dissolve to 1L to obtain the manganese, bismuth, iron and phosphorus permanent magnet alloy plating solution.

[0021] Use the Pt sheet as the anode and the copper foil as the cathode, electroplate in the manganese-bismuth-iron-phosphorus permanent magnet alloy electroplating solution obtained above, the electroplating voltage is 3.0V, the temperature of the electroplating solution is 28°C, the electroplating time is 10 minutes, and the electroplating ends Finally, the coating is washed with ethanol and water in sequence, and then dried to obtain ...

Embodiment 2

[0024] Dissolve 35g of boric acid in 0.5L of warm water, add 45g of sodium hypophosphite and 35g of sodium citrate in turn under stirring, stir thoroughly, and mix well to obtain solution A; adjust the pH of solution A with 1.0mol / L HCl 2. Under stirring, add 5g of ferrous chloride, 55g of manganese chloride, 2g of bismuth chloride and 1g of ascorbic acid in sequence. After fully stirring for 2 hours, add an appropriate amount of water to set the volume to 1L to obtain manganese, bismuth, iron and phosphorus permanent magnet alloy plating liquid.

[0025] Use the Pt sheet as the anode and the copper foil as the cathode, electroplate in the manganese-bismuth-iron-phosphorus permanent magnet alloy electroplating solution obtained above, the electroplating voltage is 2.0V, the temperature of the electroplating solution is 20°C, the electroplating time is 15 minutes, and the electroplating ends Finally, the coating is washed with ethanol and water in sequence, and then dried to ob...

Embodiment 3

[0028] Dissolve 45g of boric acid in 0.5L of warm water, add 30g of sodium hypophosphite and 42g of sodium citrate in turn under stirring, stir thoroughly, and mix well to obtain solution A; adjust the pH of solution A with 1.0mol / L HCl 2. Under stirring, sequentially add 15g of ferrous chloride, 65g of manganese chloride, 10g of bismuth chloride and 5g of ascorbic acid. After fully stirring for 2 hours, add an appropriate amount of water to set the volume to 1L to obtain manganese, bismuth, iron and phosphorus permanent magnet alloy plating liquid.

[0029] Use the Pt sheet as the anode and the copper foil as the cathode, electroplate in the manganese-bismuth-iron-phosphorus permanent magnet alloy electroplating solution obtained above, the electroplating voltage is 5.0V, the temperature of the electroplating solution is 35°C, the electroplating time is 20 minutes, and the electroplating is completed Finally, the coating is washed with ethanol and water in sequence, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coercivity | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com