Oxygen anion anti-static membrane material and preparation method thereof

A technology of anti-static film and oxygen negative ions, applied in the direction of coating, etc., can solve the problems that negative ions affect human mental state and physical and mental health, and achieve the effect of preventing and eliminating static electricity and increasing the content of negative ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

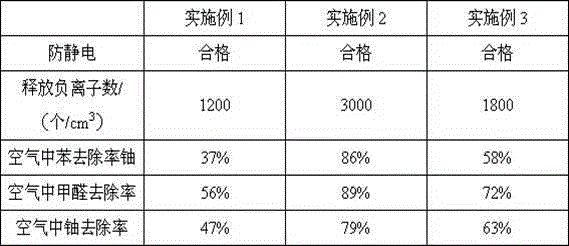

Examples

Embodiment 1

[0028] An oxygen negative ion antistatic film material, mainly made of carrier material, adhesive resin, phenolic epoxy resin, and negative ion powder; the carrier material is made according to the following ratio of raw materials by weight: 12 parts of polyvinyl chloride, 8 parts of carbonate, 13 parts of polyethylene terephthalate, 2 parts of carbon fiber; the adhesive resin is melamine formaldehyde resin or melamine urea formaldehyde resin suitable for impregnation, wherein the resin solid content is 40%; the anion The powder is prepared according to the following proportions by weight of raw materials: 12 parts of tourmaline powder and 2 parts of biomass carbon powder.

[0029] A preparation method of negative oxygen ion antistatic film material, comprising the following steps:

[0030] (1) Melting polyvinyl chloride, polycarbonate and polyethylene terephthalate at high temperature, and mixing them evenly, the melting temperature is 216°C, and spraying carbon fibers on the...

Embodiment 2

[0036] An oxygen negative ion antistatic film material, mainly made of carrier material, adhesive resin, phenolic epoxy resin, and negative ion powder; the carrier material is made according to the following ratio of raw materials by weight: 30 parts of polyvinyl chloride, 22 parts of carbonate, 30 parts of polyethylene terephthalate, 9 parts of carbon fiber; the adhesive resin is melamine formaldehyde resin or melamine urea formaldehyde resin suitable for impregnation, wherein the resin solid content is 62%; the anion The powder is prepared according to the following proportions by weight of raw materials: 22 parts of tourmaline powder and 13 parts of biomass carbon powder.

[0037] A preparation method of negative oxygen ion antistatic film material, comprising the following steps:

[0038] (1) Melt polyvinyl chloride, polycarbonate and polyethylene terephthalate at high temperature and mix them evenly. The melting temperature is 302°C. Spray carbon fibers on the surface of ...

Embodiment 3

[0044]An oxygen negative ion antistatic film material, mainly made of carrier material, adhesive resin, phenolic epoxy resin, and negative ion powder; the carrier material is made according to the following ratio of raw materials by weight: 35 parts of polyvinyl chloride, 25 parts of carbonate, 35 parts of polyethylene terephthalate, 11 parts of carbon fiber; the adhesive resin is melamine formaldehyde resin or melamine urea formaldehyde resin suitable for impregnation, wherein the resin solid content is 68%; the anion The powder is prepared according to the following proportions by weight of raw materials: 28 parts of tourmaline powder and 19 parts of biomass carbon powder.

[0045] A preparation method of negative oxygen ion antistatic film material, comprising the following steps:

[0046] (1) Melt polyvinyl chloride, polycarbonate and polyethylene terephthalate at high temperature and mix them evenly. The melting temperature is 314°C, and spray carbon fibers on the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com