Synthesis method of hydrophilic ion pair chromatography packing

A technology of ion-pair chromatography and synthesis method, which is applied in the field of ion-pair chromatography packing, which can solve the problems of difficult sulfonation reaction control, poor product consistency, and low success rate, and achieves surface hydrophilic capacity that is easy to control, low in cost, and successful high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

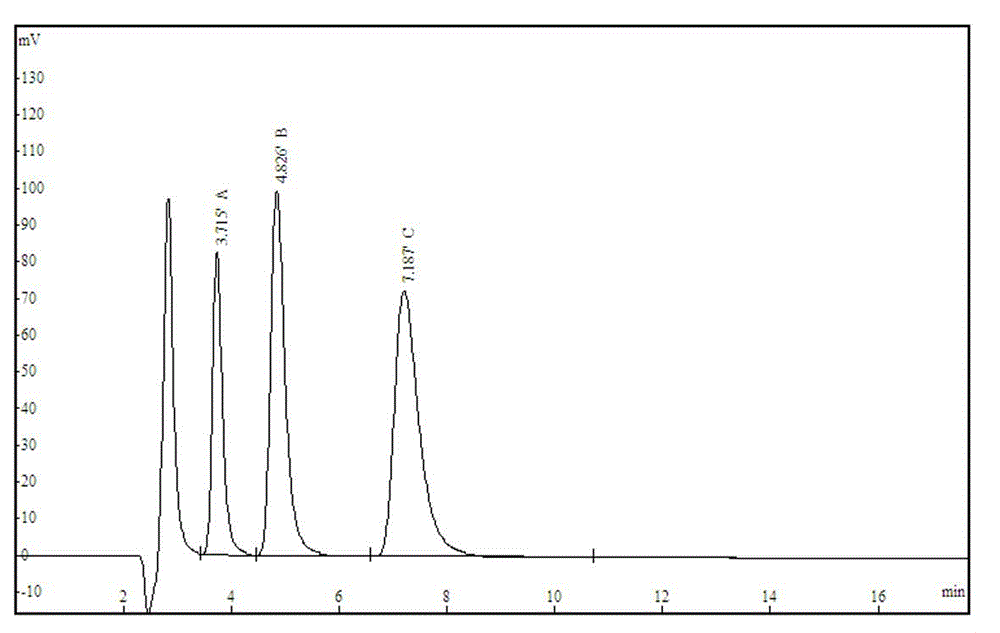

Image

Examples

Embodiment 1

[0014] Add 3 g of protective colloid reagent polyvinyl alcohol to 500 ml of deionized water and stir to dissolve. Divinyl benzene with a content of 80% and initiator (di)benzoyl peroxide dissolved in toluene were packed into a brown bottle, filled with nitrogen gas and sealed, and stored at 4 degrees Celsius for later use.

[0015] In the 1000 ml three-neck flask equipped with a stirrer and reflux condenser, add the polyvinyl alcohol solution dissolved in 1, and add 1 g of potassium styrene sulfonate, and then add 5 ml of the mixed monomer and seeds in 1 , under a nitrogen atmosphere, first stirred and swelled at 30 degrees Celsius for 24 hours, then stirred and reacted at 80 degrees Celsius for 4 hours, and finally matured and reacted at 90 degrees Celsius for 10 hours.

[0016] The presence of potassium styrene sulfonate makes the ethylstyrene-divinylbenzene polymer microspheres with a crosslinking degree of 80% synthesized by swelling polymerization become highly crossl...

Embodiment 2

[0020] The difference from 1 in Example 1 is that the protective colloid reagent is gelatin, 500 milliliters of deionized water is dissolved in 5 grams of protective colloid reagent gelatin, the content of 70% divinylbenzene and the initiator are lauryl peroxide.

[0021] The difference from 2 in Example 1 is that the gelatin solution dissolved in 1 was added to the three-necked bottle; under nitrogen atmosphere, first stirred and swelled at 25 degrees Celsius for 25 hours, then stirred and reacted at 77.5 degrees Celsius for 4.5 hours, and finally matured at The reaction was stirred at 87.5 degrees Celsius for 10.5 hours.

[0022] The presence of potassium styrene sulfonate makes the ethylstyrene-divinylbenzene polymer microspheres with a crosslinking degree of 70% synthesized by the swelling polymerization method become highly crosslinked hydrophilic ethylstyrene-divinylbenzene polymer microspheres containing sulfonic acid groups on the surface. divinylbenzene filler. T...

Embodiment 3

[0025] The difference with Example 1 is that the protective colloid reagent is light calcium carbonate, 500 milliliters of deionized water, add 10 grams of protective colloid reagent light calcium carbonate, the divinylbenzene and initiator of content 85% are n-octyl peroxide acyl.

[0026] The difference from 2 in Example 1 is that the light calcium carbonate solution dissolved in 1 is added to the three-necked bottle; under nitrogen atmosphere, first stir and swell at 35 degrees Celsius for 23 hours, then stir and react at 82.5 degrees Celsius for 3.5 hours, Finally, ripen and react at 92.5 degrees Celsius for 9.5 hours with stirring.

[0027] Potassium styrene sulfonate makes the ethylstyrene-divinylbenzene polymer microspheres with a crosslinking degree of 85% synthesized by swelling polymerization method become highly cross-linked hydrophilic ethylstyrene-divinylbenzene containing sulfonic acid groups on the surface Benzene filler. The filler is washed and dried, ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com