Laser additive manufacturing technology of high-temperature alloy parts

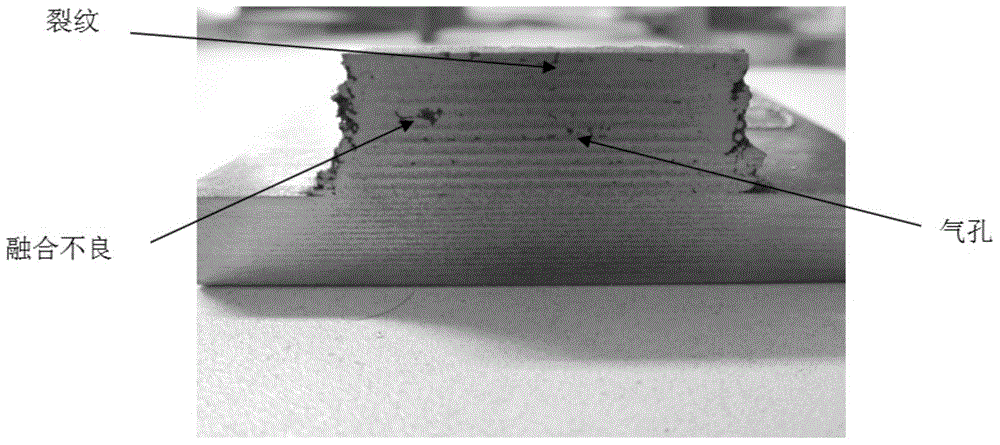

A high-temperature alloy and laser additive technology, applied in the direction of improving process efficiency, improving energy efficiency, etc., can solve problems such as poor internal quality, deformation, cracking, etc., and achieve the effect of low cost, reduced manufacturing cost, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

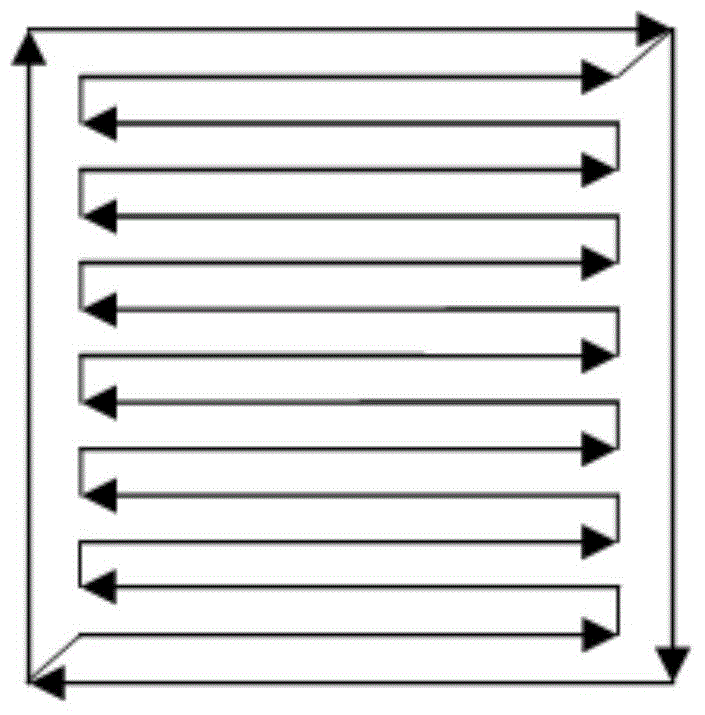

Method used

Image

Examples

Embodiment 1

[0032] In Example 1, the whole impeller test piece of the steam turbine is manufactured by the laser additive manufacturing process. The test piece is a typical thin-walled rotary piece, and the process is as follows:

[0033] (1) Determine the basic process parameters of the superalloy: the laser additive manufacturing material used is: iron-based material of grade 43-X, and the specification is -100~+200 mesh. The process experiment of optimizing the basic process parameters of iron-based materials (grade 43-X) was carried out by using the orthogonal experiment method, and the effects of various process parameters including laser power, scanning speed, powder feeding rate, scanning distance, and layer thickness on the laser gain were obtained. The influence law of the shape and size of the forming layer of the material manufacturing, and then determine the specific process parameter range of the iron-based material (grade 43-X), as shown in Table 1.

[0034] Table 1

[0035...

Embodiment 2

[0046] This embodiment is an experimental piece of an engine blade manufactured by a laser additive manufacturing process, and adopts the same laser additive manufacturing process equipment as in Example 1 ( Figure 6 ),The difference is:

[0047] The superalloy powder is a nickel-based material (brand In625), and the determined range of process parameters is shown in Table 3.

[0048] Table 3 process parameter range

[0049] Experimental parameters

scope

laser power

2200W

scanning speed

8mm / s

Powder feeding rate

1g / min

0.9mm

scan pitch

1mm

[0050] Such as Figure 7 Shown is the actual picture of the experimental piece of the engine blade manufactured by the manufacturing process of this embodiment. With the relevant technical improvement measures of this embodiment, the processing quality, internal structure and related mechanical properties of the parts can all reach the industri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com