Preparation method for gliclazide tablet composition

A special tablet and composition technology, applied in the field of gliclazide tablet composition, can solve the problems of poor reproducibility, low disintegrant dosage, low process controllability, etc., and achieve process controllability The effect of high performance, uniform product properties, and operable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

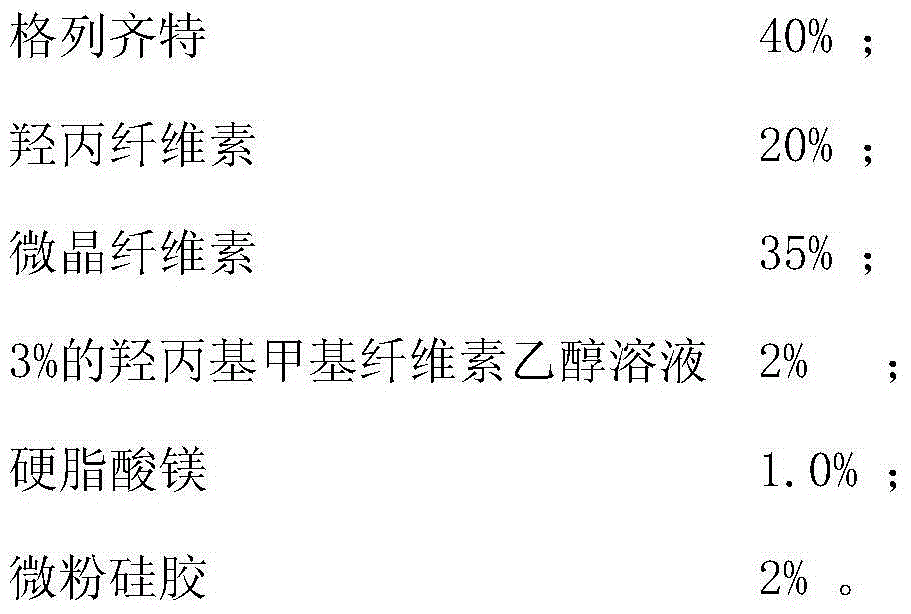

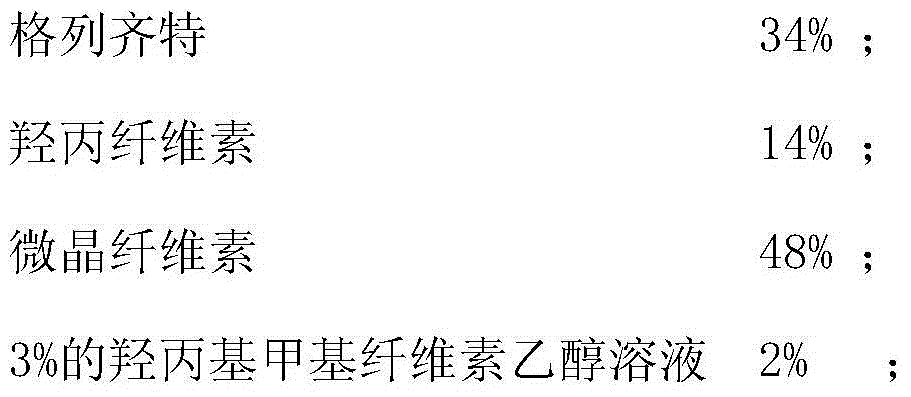

[0019] (Example 1) Weigh each main and auxiliary material according to the following proportioning, with a total amount of 200 grams:

[0020]

[0021] (1) Granulation: Weigh hypromellose and put it in a stainless steel bucket, add the calculated amount of 95% ethanol and purified water of the same weight, stir evenly to make a 3% hydroxypropyl methylcellulose ethanol solution as a binder agent. Weigh the prescribed amount of gliclazide, hydroxypropyl cellulose, and microcrystalline cellulose, add them to the wet granulator and stir for 5 minutes, then add the binder, stir for 3-4 minutes and discharge, and use a 16-mesh nylon sieve to shake Granulation on the type granulator;

[0022] (2) Drying: Dry the wet granules in a hot air circulation oven, the temperature is controlled at 75°C, dried for 3.5 hours, and the moisture content of the granules is controlled at 2.0%;

[0023] (3) Granulation and blending: the granules are sized on a swing granulator with a 16-mesh stai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com