Method for preparing enzymic method modified whey protein soluble polymer

A whey protein and soluble technology, applied in the field of preparation of enzymatically modified whey protein soluble polymer, can solve problems such as few reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

[0014] 1. Preparation of whey protein solution

[0015] Prepare whey protein with a mass concentration of 10% (w / v), weigh 11.16g of WPI, dissolve it in deionized water, stir gently for 60min, refrigerate at 4°C for 12h to fully hydrate the protein, and set aside.

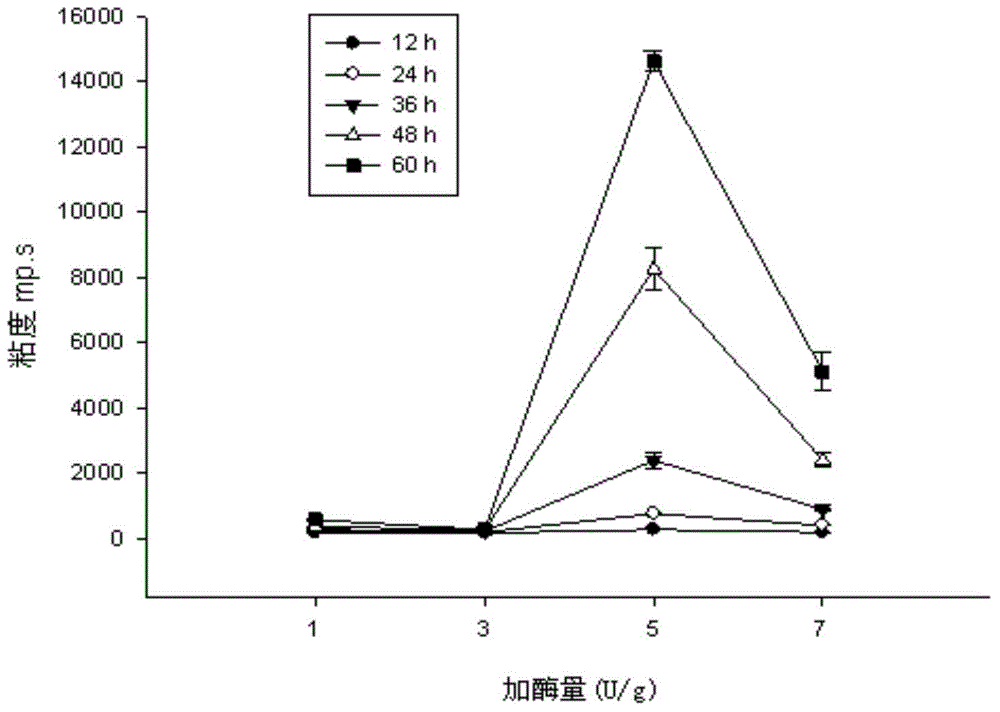

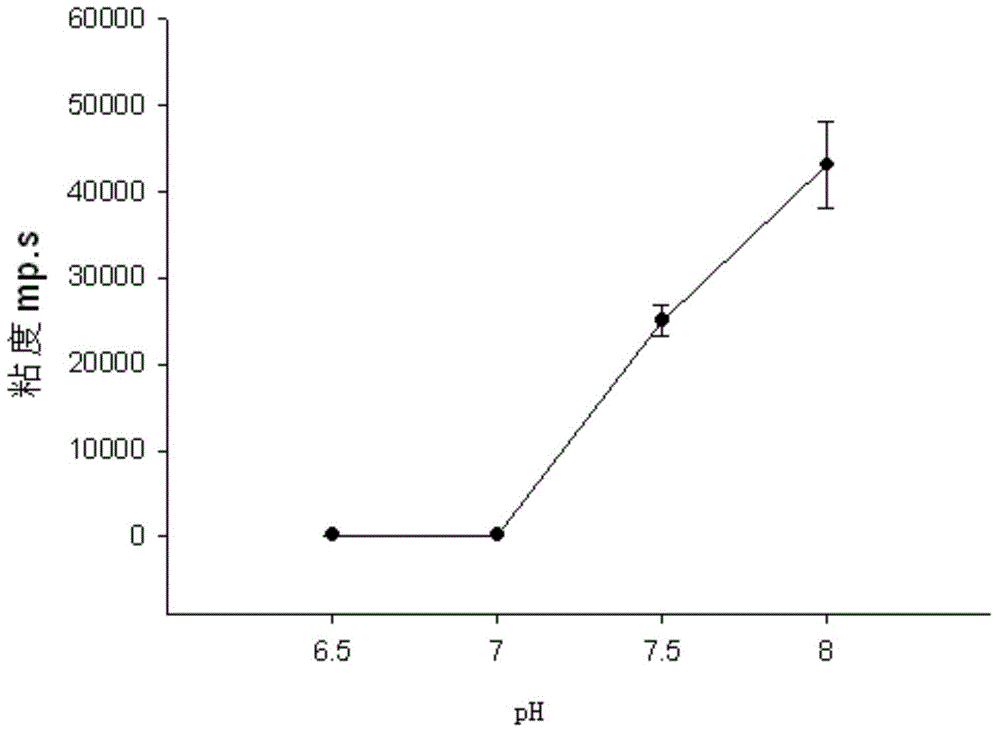

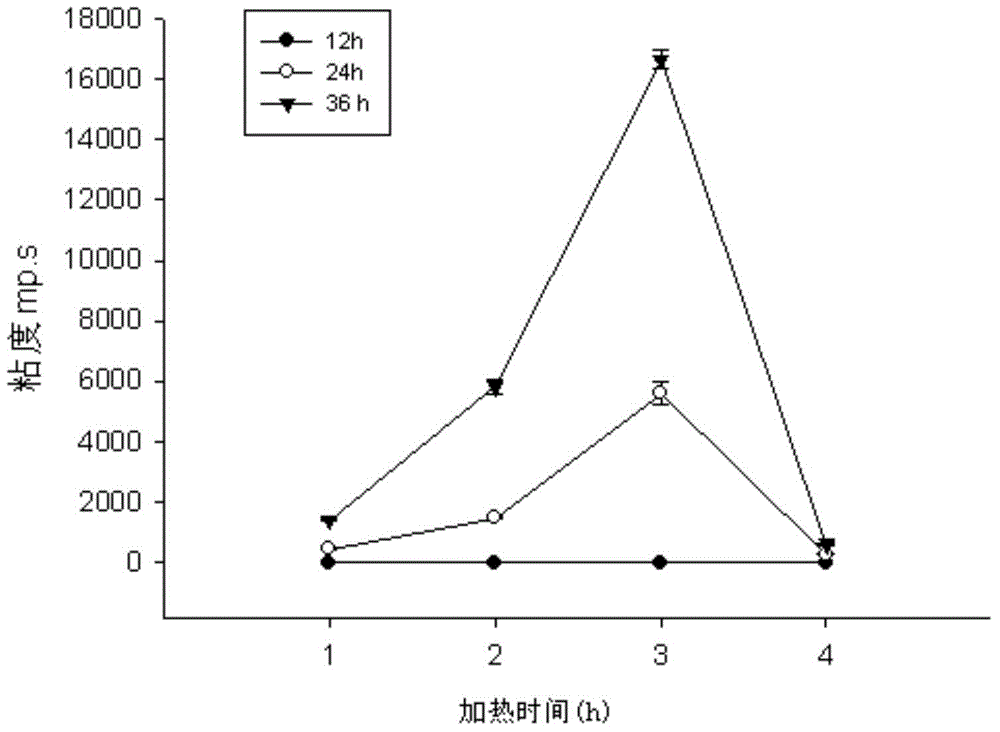

[0016] 2. TG Catalyzed Polymerization

[0017] 10% WPI is preheated and stirred for 5 minutes, the pH is adjusted to the corresponding value, heated at 85°C for 5 minutes, quickly cooled to room temperature, added TG enzyme, kept at the corresponding temperature for a certain period of time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com