Beta-cyclodextrin recovering method

A recovery method, cyclodextrin technology, applied in the field of β-cyclodextrin recovery, can solve the problem that the high cholesterol removal rate cream whipping and foam stability cannot be satisfied at the same time, and β-cyclodextrin cannot be recycled , unfavorable cream foam stability and other problems, to achieve the effect of good whipping, good foam stability and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

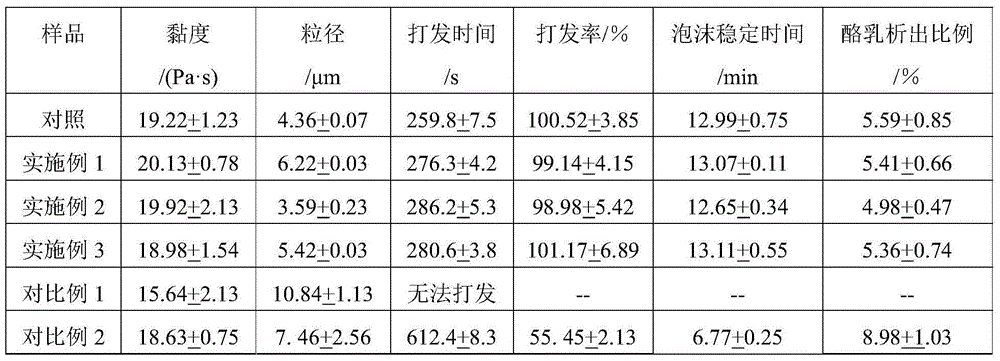

Examples

preparation example Construction

[0057] Preparation of cholesterol standard solution: Accurately weigh 200mg of cholesterol, dissolve it with n-hexane and dilute to 100ml to obtain a cholesterol standard stock solution with a mass concentration of 2g / L; then absorb 10ml of the stock solution and dilute to 100ml with n-hexane to obtain a mass concentration It is 0.2g / L cholesterol standard working solution.

[0058] 1.2 Measurement wavelength selection

[0059] Take 0 and 0.5ml of cholesterol standard working solution, evaporate the solvent in a vacuum drying oven at 60°C, add 0.2ml of glacial acetic acid, 0.4ml of o-phthalaldehyde-ethanol solution (1mg / ml), 4ml of mixed acid (1:1 on ice Acetic acid-concentrated sulfuric acid), vortex mixing, cooling, color development for 15min, scanning at 480-650nm, the result is a maximum absorption at 553nm, so the measurement wavelength is selected as 553nm.

[0060] 1.3 Establishment of working curve

[0061] Aspirate 0, 0.2, 0.4, 0.6, 0.8 and 1ml of the cholesterol w...

Embodiment 1

[0071] 1. Cross-linking reaction of β-cyclodextrin and adipic acid

[0072] Add 100g of β-CD to 80mL of distilled water, stir at room temperature for 30min, add 3g of adipic acid, adjust the pH to 10 with 1M sodium hydroxide solution, continue to stir the mixture at room temperature for 1h, then add 1M of acetic acid The solution was adjusted to pH 4. Filter the solution with Whatman No. 2 filter paper, remove the filter residue and wash it with 150ml of distilled water three times, then dry the filter residue in an oven at 40°C for 12 hours, and the obtained product is the cross-linked product of β-cyclodextrin and adipic acid.

[0073] Wherein, the filtrate after filtration by Whatman No. 2 filter paper is collected and measured to determine the content of β-cyclodextrin, and the amount of β-cyclodextrin cross-linked with adipic acid can be calculated by the following formula:

[0074] Amount of cross-linked β-cyclodextrin (gβ-cyclodextrin / g adipic acid)=A-B / C, where A is t...

Embodiment 2

[0084] 1. Cross-linking reaction of β-cyclodextrin and adipic acid

[0085] Add 100g of β-CD to 80mL of distilled water, stir at room temperature for 3h, add 7g of adipic acid, adjust the pH to 10 with 1M sodium hydroxide solution, continue to stir the mixture at room temperature for 90min, then add 1M of acetic acid The solution was adjusted to pH 4. Use whatman No. 2 filter paper to filter the solution, remove the filter residue and wash it with 150ml distilled water for 4 times, then dry the filter residue in an oven at 70°C for 4 hours, and the obtained product is the cross-linked product of β-cyclodextrin and adipic acid. The final filtrate was collected to measure the content of β-cyclodextrin, and the amount of β-cyclodextrin cross-linked with adipic acid can be calculated by the following formula:

[0086] Amount of cross-linked β-cyclodextrin (gβ-cyclodextrin / g adipic acid)=A-B / C, where A is the total amount of β-cyclodextrin added, i.e. 100g; B is the β-cyclodextrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com