A high-temperature anti-corrosion device for coal-fired boilers with self-cooling function

A technology for coal-fired boilers and anti-corrosion devices, which is applied to boiler water pipes, combustion chambers, combustion methods, etc., can solve the problems of slagging and high-temperature corrosion of internal components, and avoid slagging and high-temperature corrosion. Anti-wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

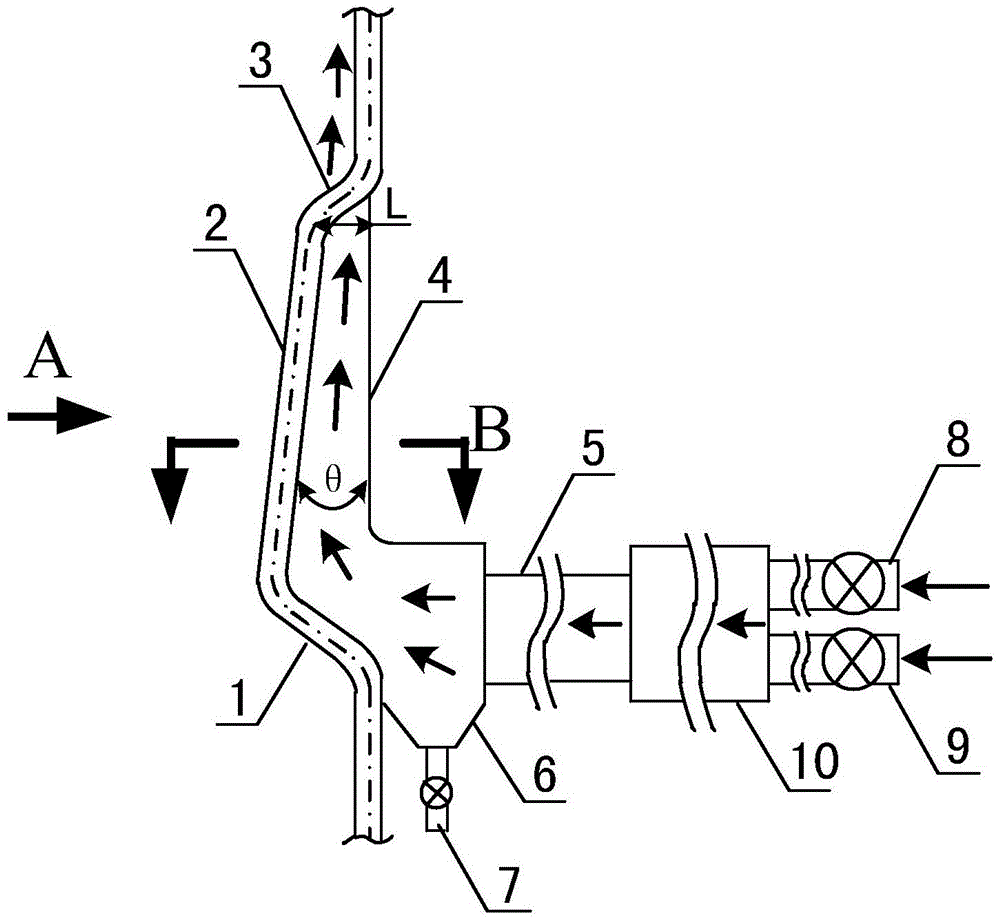

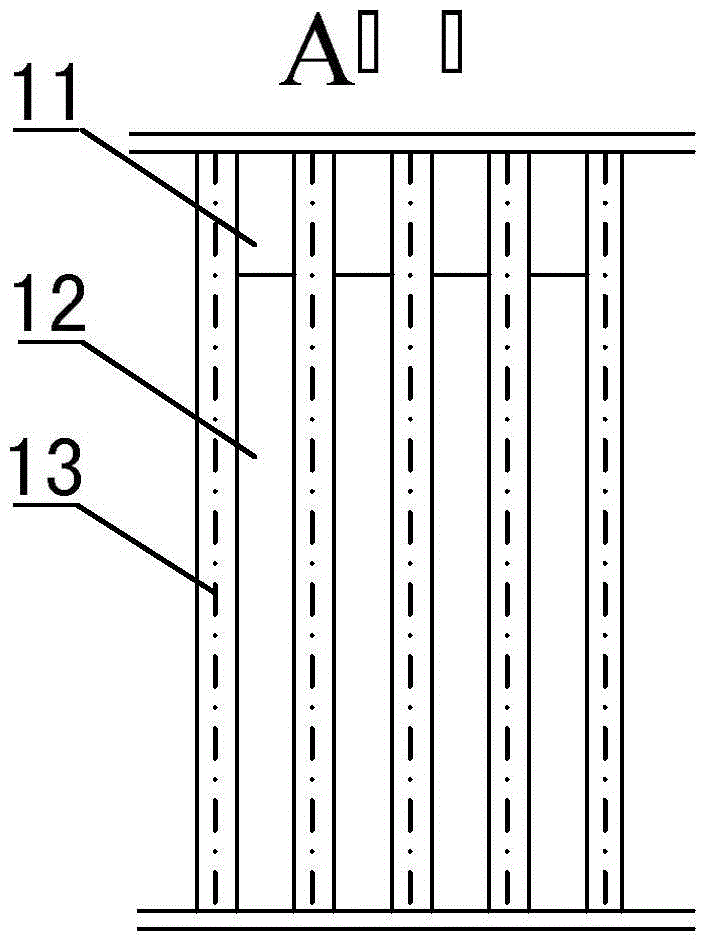

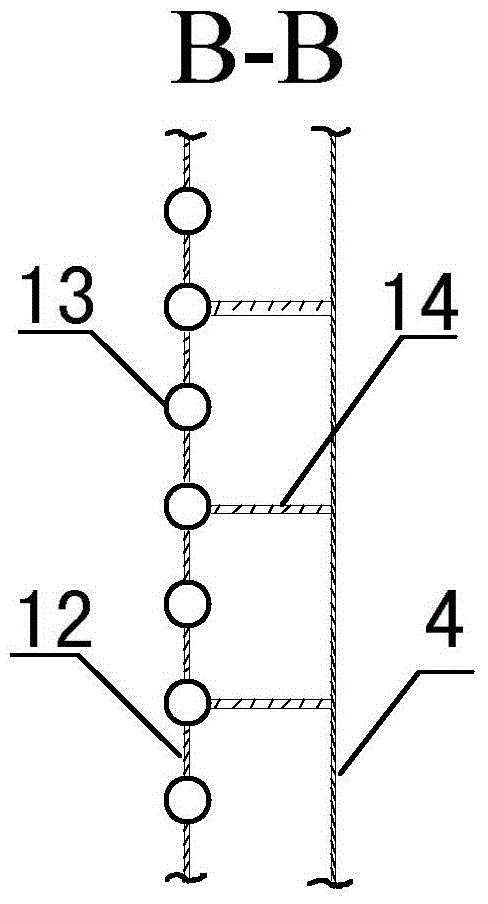

[0028] The wall-attached wind device includes: a wall-attached bellows, an ash hopper, an introduction section recessed into the water-cooled wall in the furnace, a diversion section recessed into the water-cooled wall in the furnace, a lead-out section recessed into the water-cooled wall in the furnace, and a wall-attached air blower. Nozzles, wall-attached air inlet branch pipes and ash discharge pipes; the water-cooled wall recessed into the furnace is located below the high-temperature corrosion-prone area; the diversion section of the water-cooled wall recessed into the furnace is inclined to the furnace wall and the vertical direction presents a certain angle of inclination; The wall-attached air nozzle is set at the lead-out section of the water-cooled wall in the recessed furnace, which is composed of a slit formed by cutting the fins connected to the water-cooled wall tube; the ash bucket is arranged under the wall-attached bellows; The wall bellows are fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com