Multilayer ultra corrosion resistant nickel-chromium plating part and manufacturing method thereof

A nickel-plating and component technology, applied in the multi-layer super-corrosion-resistant nickel-chromium plating component and its manufacturing field, can solve the problems of unreachable corrosion resistance, trivalent chromium electroplating, and easy brittleness of the coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

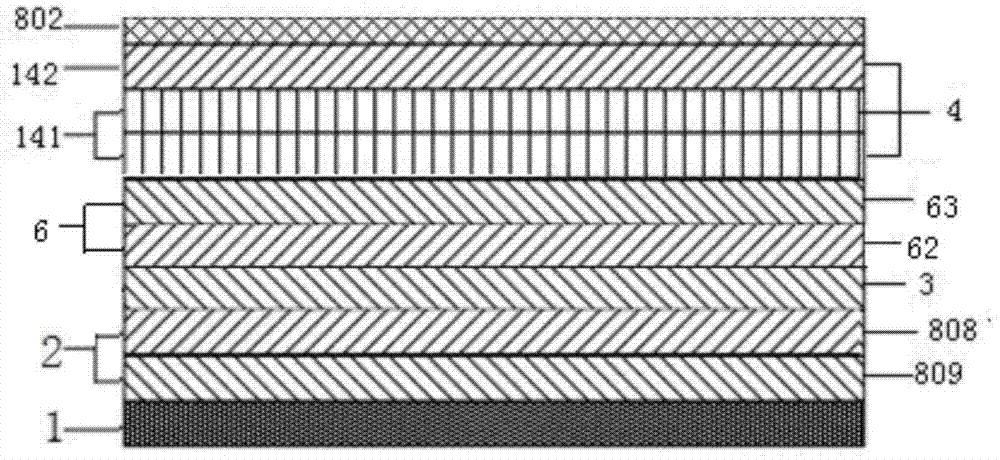

[0114] Such as figure 1 As shown, the multilayer super corrosion-resistant nickel-chrome plated part of the present embodiment includes: base material 1 (ABS material); pretreatment coating 2 includes chemical nickel layer 809, primer nickel layer 808 and copper plating layer 3 , the chemical nickel layer 809 is deposited on the entire substrate 1, and the bottom nickel layer 808 is deposited on the chemical nickel layer 809, and the copper plating layer 3 is formed on the bottom nickel layer 808; and the base layer 6, which is formed on the copper plating On the layer 3, wherein the base layer 6 includes a semi-gloss nickel layer 62 and a full-gloss nickel layer 63, the semi-gloss nickel layer 62 is formed on the copper-plated layer 3, and the full-gloss nickel layer 63 is formed on the semi-gloss nickel layer 62; and function Layer 4, which is formed on the full-bright nickel layer 63 of the base layer 6, wherein the functional layer 4 includes a low-potential nickel layer 1...

Embodiment 2

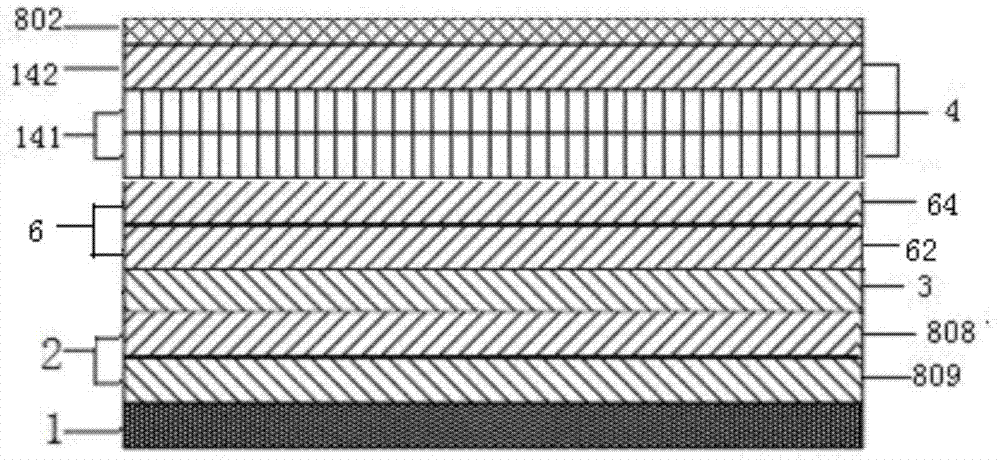

[0116] Such as figure 2 As shown, the multilayer super corrosion-resistant nickel-chrome plated part of the present embodiment includes: base material 1 (ABS material); pretreatment coating 2 includes chemical nickel layer 809, primer nickel layer 808 and copper plating layer 3 , the chemical nickel layer 809 is deposited on the entire substrate 1, and the bottom nickel layer 808 is deposited on the chemical nickel layer 809, and the copper plating layer 3 is formed on the bottom nickel layer 808; and the base layer 6, which is formed on the copper plating On the layer 3, wherein the base layer 6 includes a semi-gloss nickel layer 62 and a satin nickel layer 64, the semi-gloss nickel layer 62 is formed on the copper plating layer 3, and the satin nickel layer 64 is formed on the semi-gloss nickel layer 62; and the functional layer 4, which is formed on the satin nickel layer 64 of the base layer 6, wherein the functional layer 4 includes a low-potential nickel layer 141 and a...

Embodiment 3

[0118] Such as image 3 As shown, the multilayer super corrosion-resistant nickel-chrome plated part of the present embodiment includes: base material 1 (ABS material); pretreatment coating 2 includes chemical nickel layer 809, primer nickel layer 808 and copper plating layer 3 , the chemical nickel layer 809 is deposited on the entire substrate 1, and the bottom nickel layer 808 is deposited on the chemical nickel layer 809, and the copper plating layer 3 is formed on the bottom nickel layer 808; and the base layer 6, which is formed on the copper plating layer 3, wherein the base layer 6 includes a semi-bright nickel layer 62, a high-sulfur nickel layer 61 and a full-bright nickel layer 63, the semi-bright nickel layer 62 is formed on the copper plating layer 3, and the high-sulfur nickel layer 61 is formed on the semi-bright nickel On the layer 62, a full-bright nickel layer 63 is formed on the high-sulfur nickel layer 61; and a functional layer 4, which is formed on the fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com