A kind of blue fluorescent powder for white light LED and preparation method thereof

A blue phosphor, white light technology, applied in the field of fluorescent materials, can solve problems such as increased experimental risk, limitation of luminous efficiency, complicated preparation process, etc., and achieves good chemical stability and thermal stability, easy to operate, and a wide range of raw material sources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of Sc 3.996 Ce 0.004 Al 6 Si 3 o 21 , according to the chemical formula Sc 3.996 Ce 0.004 Al 6 Si 3 o 21 The stoichiometric ratio of each element in is weighed scandium oxide Sc 2 o 3 : 2.762 grams, cerium nitrate Ce (NO 3 ) 3 ·6H 2 O: 0.018 g, aluminum oxide Al 2 o 3 : 3.059 g, silicon dioxide SiO 2 : 1.803 g, ground and mixed in an agate mortar, pre-calcined in an air atmosphere, the pre-calcined temperature is 400 ° C, the pre-calcined time is 8 hours, then cooled to room temperature, the sample is taken out, fully ground and mixed uniformly, in the Activated carbon powder is calcined in a reducing atmosphere of CO generated by combustion. The calcination temperature is 1200°C, and the calcination time is 10 hours. After cooling to room temperature, the sample is taken out, ground and mixed evenly to obtain phosphor.

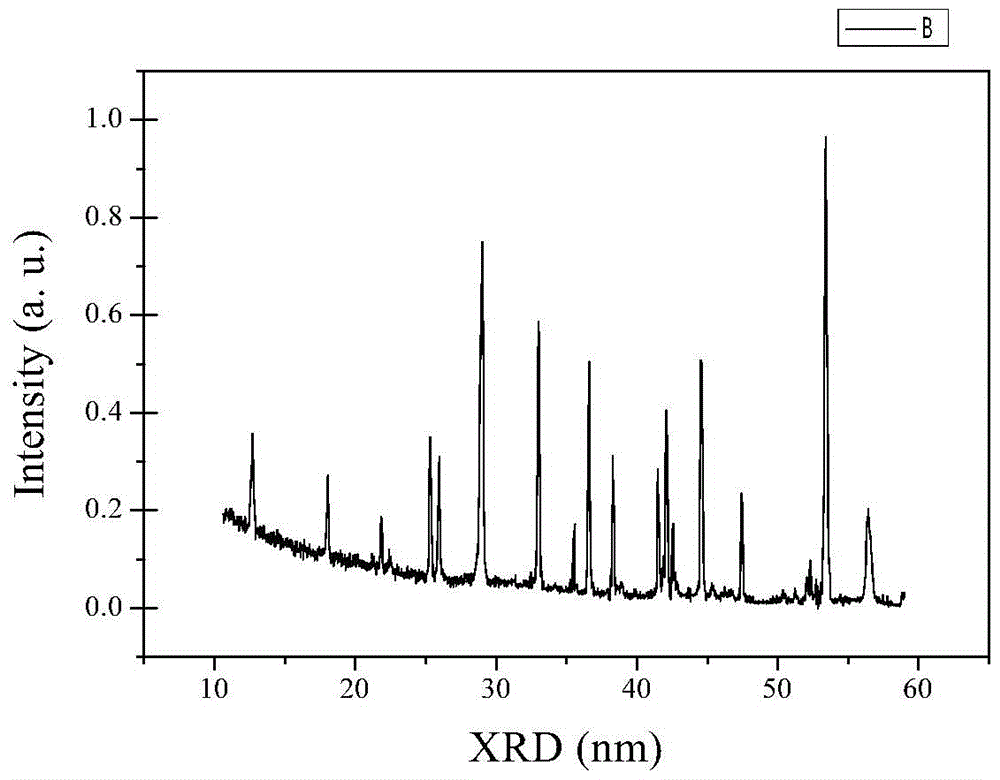

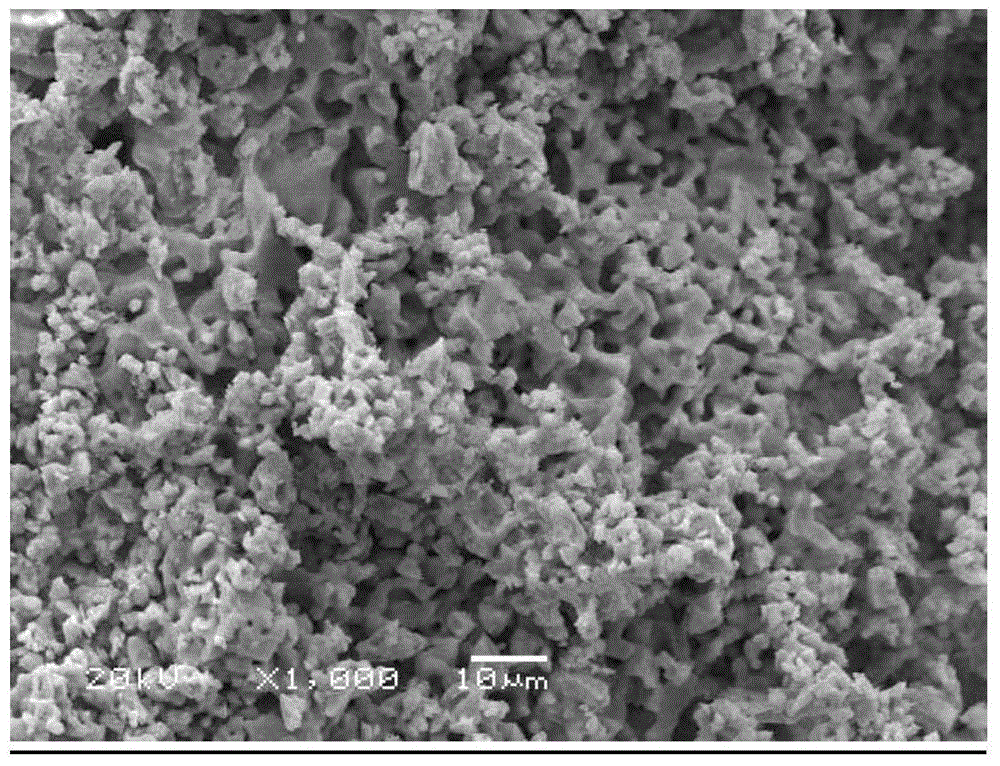

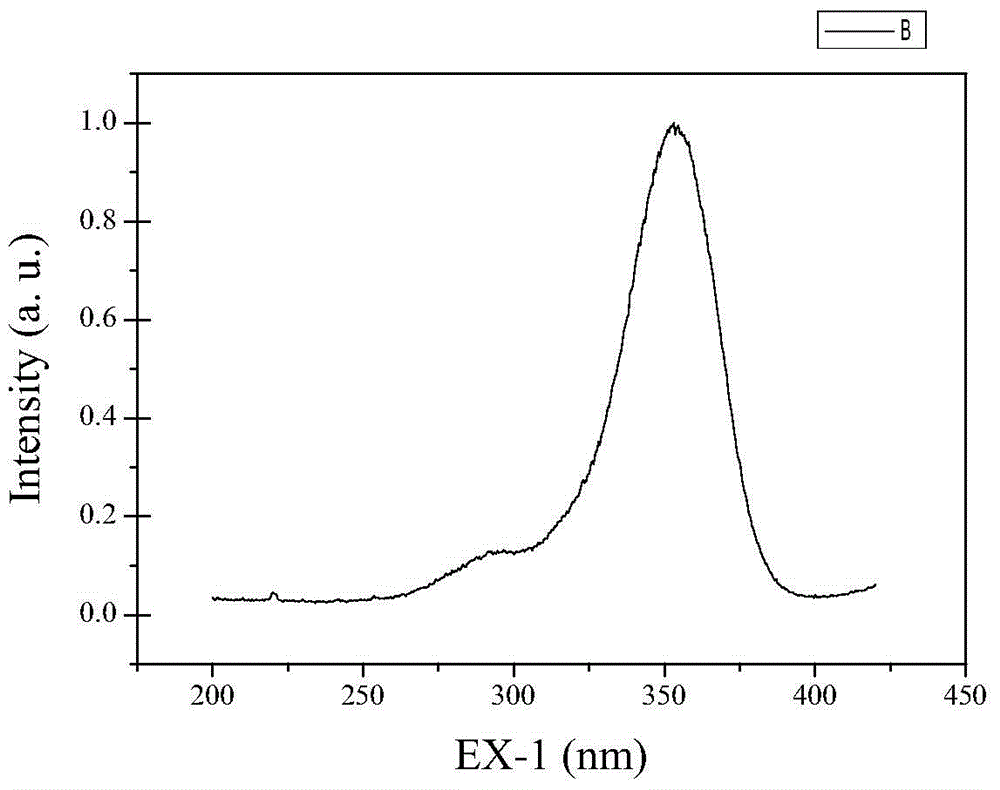

[0036] See attached figure 1 , which is the X-ray powder diffraction pattern of the material sample prepared according to...

Embodiment 2

[0042] Preparation of Sc 3.96 Ce 0.04 Al 6 Si 3 o 21 , according to the chemical formula Sc 3.96 Ce 0.04 Al 6 Si 3 o 21 The stoichiometric ratios of the elements in the 3 ) 3 ·3H 2 O: 3.762 grams, cerium oxide CeO 2 : 0.023 g, alumina Al 2 o 3 : 1.020 g, silicon dioxide SiO 2 : 0.601 g, ground and mixed in an agate mortar, pre-calcined in an air atmosphere, the pre-calcined temperature is 100 ° C, the pre-calcined time is 10 hours, then cooled to room temperature, the sample is taken out, fully ground and mixed uniformly, in the composition 95% N 2 +5%H 2 Calcined in a mixed gas of 800° C. for 12 hours, cooled to room temperature, took out the sample, ground and mixed evenly to obtain phosphor.

[0043] The main structural properties, sample morphology, excitation spectrum, luminescence spectrum and decay curve of the sample prepared in this example are similar to those in Example 1.

Embodiment 3

[0045] Preparation of Sc 3.4 Ce 0.6 Al 6 Si 3 o 21 , according to the chemical formula Sc 3.4 Ce 0.6 Al 6 Si 3 o 21 The stoichiometric ratio of each element in is weighed scandium oxide Sc 2 o 3 : 0.470 g, cerium nitrate Ce (NO 3 ) 3 ·6H 2 O: 0.521 g, aluminum nitrate Al(NO 3 ) 3 9H 2 O: 4.502 g, silicon dioxide SiO 2 : 0.361 g, ground and mixed uniformly in an agate mortar, pre-calcined in an air atmosphere, the pre-calcined temperature is 600 ° C, the pre-calcined time is 3 hours, then cooled to room temperature, and the sample is taken out; fully ground and mixed uniformly, in the Activated carbon powder is calcined in a reducing atmosphere of CO generated by combustion, the calcination temperature is 1300°C, the calcination time is 4 hours, and then cooled to room temperature, the sample is taken out, ground and mixed evenly to obtain the phosphor.

[0046] The main structural properties, sample morphology, excitation spectrum, luminescence spectrum and de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com