High-temperature-resistant plugging agent for drilling fluid and preparation method thereof

A technology of drilling fluid and high temperature resistance, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of oil phase increasing drilling cost, complexity, well wall collapse and block, etc., and achieves strong temperature adaptability, Stable performance and the effect of stabilizing the well wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

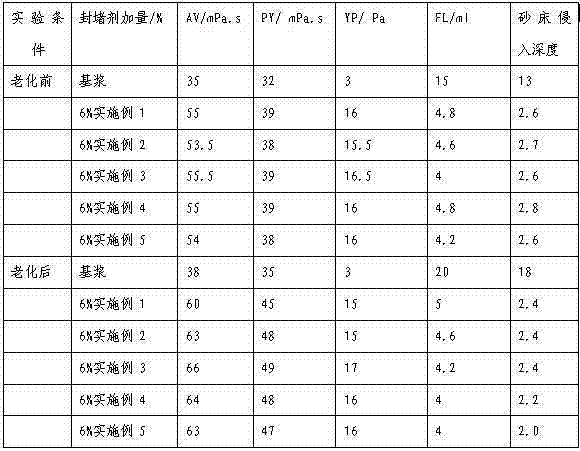

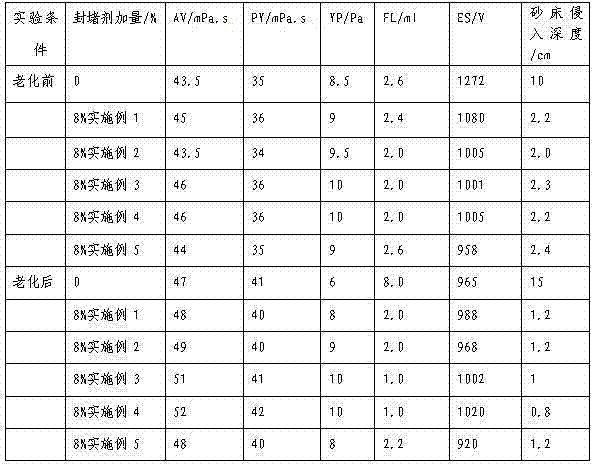

Examples

Embodiment 1

[0018] 20 parts of mineral fiber materials,

[0019] 30 parts of asphalt particles,

[0020] 30 parts of inorganic elastic particles,

[0021] 20 parts of fine rubber powder,

[0022] 30 parts of superfine calcium carbonate,

[0023] 5 parts of lignite resin;

[0024] Add mineral fiber materials, asphalt particles, inorganic elastic particles, fine rubber powder, superfine calcium carbonate, and lignite resin into a dry mixer according to the above weight parts, and dry blend for 60 minutes to obtain a product. The obtained drilling fluid plugging agent is added to oil-based drilling fluid and water-based drilling fluid respectively for performance testing.

[0025] Among them, the ratio of sepiolite and wollastonite fibers used in mineral fiber materials is 1:9.

Embodiment 2

[0027] 15 parts of mineral fiber materials,

[0028] 20 parts of asphalt particles,

[0029] 20 parts of inorganic elastic particles,

[0030] 10 parts of fine rubber powder,

[0031] 30 parts of superfine calcium carbonate,

[0032] Lignite resin 5 parts

[0033] Among them, the ratio of sepiolite and wollastonite fibers used as mineral fiber materials is 9:1.

[0034] Add mineral fiber materials, asphalt particles, inorganic elastic particles, fine rubber powder, superfine calcium carbonate, and lignite resin into a dry mixer according to the above weight parts, and dry blend for 60 minutes to obtain a product. The obtained drilling fluid plugging agent is added to oil-based drilling fluid and water-based drilling fluid respectively for performance testing.

Embodiment 3

[0036] 10 parts of mineral fiber materials,

[0037] 10 parts of asphalt particles,

[0038] 20 parts of inorganic elastic particles,

[0039] 5 parts of fine rubber powder,

[0040] 20 parts of superfine calcium carbonate,

[0041] Lignite resin 0 parts;

[0042] Among them, the ratio of sepiolite and wollastonite fibers used as mineral fiber materials is 1:1.

[0043] Add mineral fiber materials, asphalt particles, inorganic elastic particles, fine rubber powder, superfine calcium carbonate, and lignite resin into a dry mixer according to the above weight parts, and dry blend for 60 minutes to obtain a product. The obtained drilling fluid plugging agent is added to oil-based drilling fluid and water-based drilling fluid respectively for performance testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com