Waterproof anti-wear oil paint for wooden desks/chairs and preparation method thereof

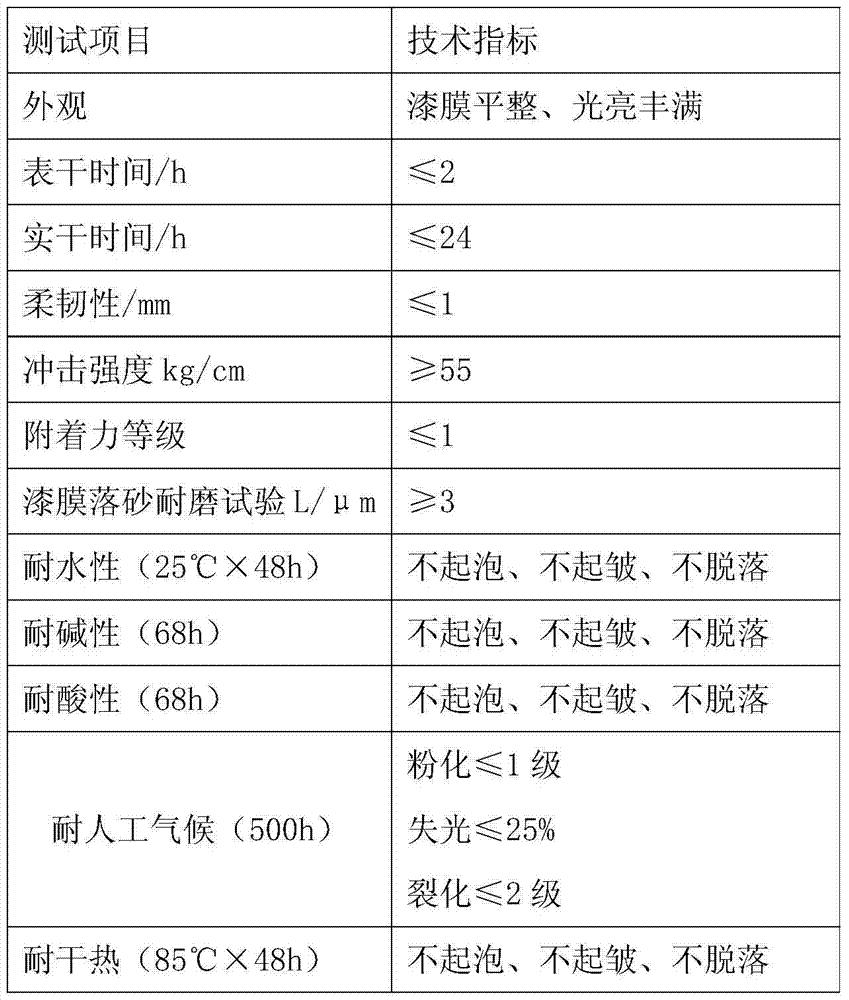

A wear-resistant paint, table and chair technology, applied in the field of paint, can solve the problems of shortened service life, deformation and cracking of wooden tables and chairs, and achieve the effects of superior water and heat resistance, dense and tough paint film, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0012] The paint of this embodiment is made from the following raw materials in parts by weight: silica sol 15, cobalt nitrate 5, imidazolidinyl urea 3, platinum trioxide 2, ethylene glycol ethyl ether 2, ferrocene 5, aromatic polyurethane acrylate 35, ring Oxyacrylate 18, Methyl Methacrylate 14, Benzyltriphenylphosphine Chloride 2, Montmorillonite Powder 6, Tetraacicular Zinc Oxide Whiskers 12, Diisocyanate 2, Crosslinking Agent TAC 3, Glycerin Triacetate 12. Additive 6, xylene 12, butyl acetate 12.

[0013] The auxiliary agent is made of the following raw materials in parts by weight: hectorite 5, anilinomethyltriethoxysilane 3, basic magnesium carbonate 4, polyisobutylene 5, N-vinylpyrrolidone 2, propyl gallate 2. Propylene Glycol Methyl Ether Propionate 15; the preparation method is as follows: first mix and disperse hectorite and anilinomethyltriethoxysilane for 30 minutes to obtain modified hectorite for later use, and then mix polyisobutylene, N-ethylene Pyrrolidone an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com