Preparation method of epoxy glass flake coating for oceanic tidal range/splash zone

A technology of epoxy glass and splash zone, applied in the field of coatings, to achieve high cross-linking density, outstanding cathodic disbondment resistance, and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

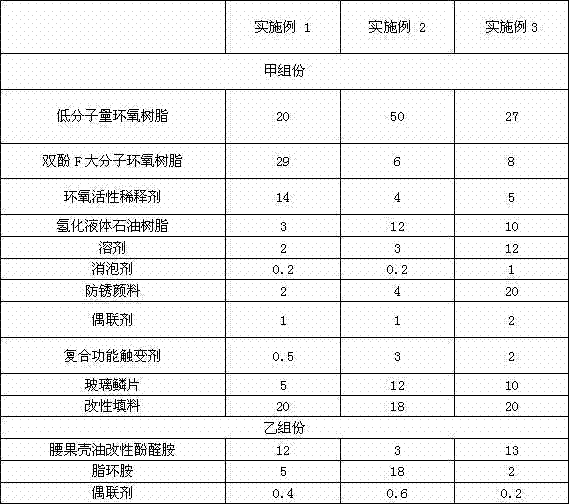

[0043] The present invention is a preparation method of epoxy glass flake paint for marine tidal range / splash area. The preparation method of the present invention includes component confirmation and weight ratio of each raw material, preparation of composite functional thixotropic agent, modified glass The preparation of flakes, the preparation of modified fillers, the preparation of amine composite curing agent, the preparation of component A, the preparation of component B and the blending ratio of component A and component B.

[0044] It is recommended that the glycidyl ether compounds used as epoxy reactive diluents have either a diepoxy functional group or a triepoxy functional group.

[0045] BYK-066N, BYK-067N, BYK-020, BYK-065, BYK-052, BYK-1752, BYK-A560, YK-A550, BYK-054, BYK-A535, BYK-1790, BYK used as defoamer -A530, BYK-070, BYK-085 are all produced by BYK.

[0046] The trade name of γ-aminopropyltriethoxysilane in the coupling agent used in component A or B is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com