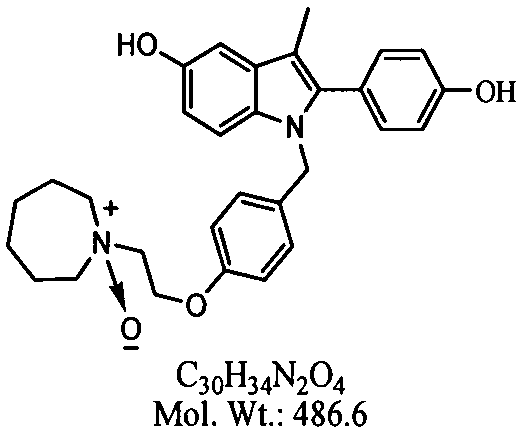

Separation preparation method of bazedoxifene acetate impurity A

A bazedoxifene acetate and impurity technology, applied in the field of reference substance research, can solve the problems of low yield and difficulty in obtaining impurity A with a purity above 96%, and achieve the goal of optimizing chromatographic conditions, shortening separation time, and ensuring stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

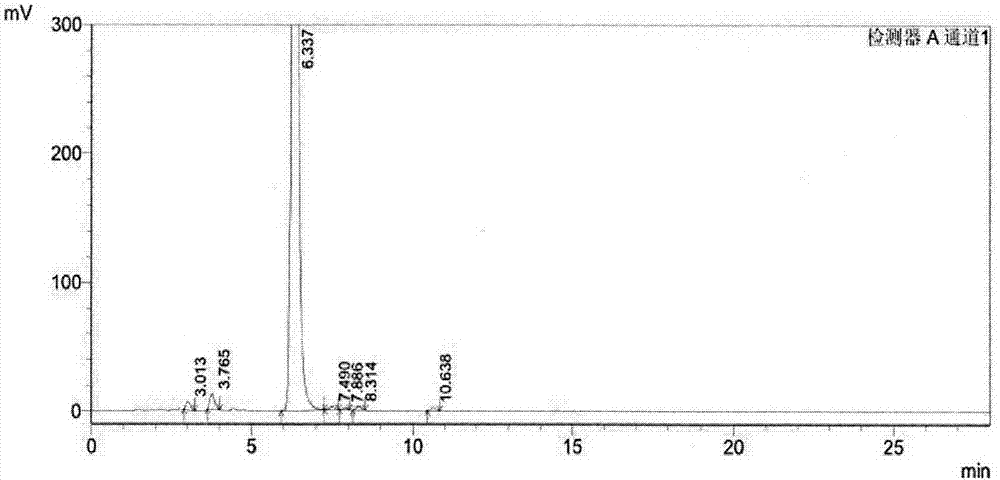

Image

Examples

Embodiment 1

[0023] In this example, 80% bazedoxifene was used as raw material, and 5 μm C 18 The bonded phase filler is a chromatographic column, and a solution containing 0.01M dipotassium hydrogen phosphate (PH8.3)-acetonitrile (40:60, volume ratio) is used as the eluting solvent. The specific process steps are as follows:

[0024] 1. Sample pretreatment

[0025] Add bazedoxifene to the eluting solvent to dissolve, add 3% hydrogen peroxide, let stand for half an hour, dilute the bazedoxifene solution to a concentration of 1 mg / ml with the eluting solvent, and filter through a 0.22 μm microporous membrane.

[0026] 2. Column handling

[0027] The preparative high-performance liquid chromatography column was selected as the stationary phase produced by Japan Sheshido Company as C 18 A preparative column (5 μm, 20×250 mm) was used to equilibrate the chromatographic column with an eluting system solution of about 5 times the column volume.

[0028] 3. Sample loading

[0029] The filtere...

Embodiment 2

[0039] In this example, 90% bazedoxifene was used as raw material, and 10 μmC 18 The bonded phase filler is a chromatographic column, and a solution containing 0.01M dipotassium hydrogen phosphate (PH8.3)-acetonitrile (35:65, volume ratio) is used as the eluting solvent. The specific process steps are as follows:

[0040] 1. Sample pretreatment

[0041] Add bazedoxifene to the elution solvent to dissolve, add 3% hydrogen peroxide, let it stand for 1 hour, dilute it with the elution solvent to a bazedoxifene solution with a concentration of 5 mg / ml, and filter through a 0.22 μm microporous membrane.

[0042] 2. Column handling

[0043] The preparative high-performance liquid chromatography column is selected as a self-packed preparative column, and the particle size of the filler is 10 μm C 8 Bonded phase filler (10μm, 75×250mm), equilibrate the chromatographic column with the elution system solution of about 10 times the column volume.

[0044] 3. Sample loading

[0045] T...

Embodiment 3

[0053] In this example, 85% bazedoxifene was used as raw material, and 10 μm C 18 The bonded phase filler is a chromatographic column, and a solution containing 0.01M dipotassium hydrogen phosphate (PH8.3)-acetonitrile (40:60, volume ratio) is used as the eluting solvent. The specific process steps are as follows:

[0054] 1. Sample pretreatment

[0055] Add bazedoxifene to the elution solvent to dissolve, add 3% hydrogen peroxide, let stand for half an hour, dilute the bazedoxifene solution to a concentration of 5 mg / ml with the elution solvent, and filter through a 0.45 μm microporous membrane.

[0056] 2. Column handling

[0057] The preparative high-performance liquid chromatography column is selected as a self-packed preparative column, and the particle size of the filler is 10 μm C 18 Bonded phase filler (10μm, 75×250mm), equilibrate the chromatographic column with the elution system solution of about 10 times the column volume.

[0058] 3. Sample loading

[0059] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com