A method for treating oil and gas field drilling waste fluid

A drilling waste fluid and treatment method technology, applied in water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problems of manpower and material resources, difficulty in building small volume, difficulty in automation, etc. Achieve the effects of less amount of chemicals, strong sewage adaptability, and reduced treatment difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with specific embodiments of the present invention.

[0021] In one embodiment of the present invention, the drilling waste fluid treatment method includes: using microwave water treatment equipment to coagulate and deoil the drilling waste fluid, and subject the coagulated and deoiled drilling waste fluid to sedimentation treatment to obtain Lower sludge and supernatant.

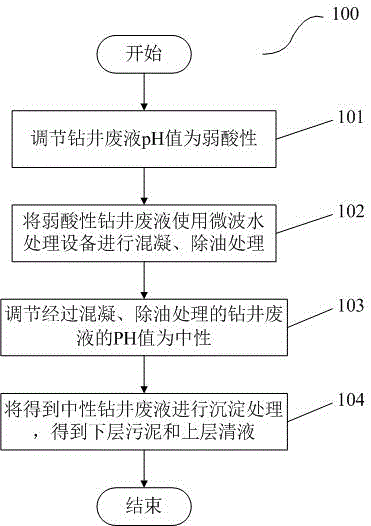

[0022] refer to figure 1 , figure 1 Shown is a flow diagram of one embodiment 100 of the method of the present invention. Embodiment 100 includes steps 101 to 104 as follows.

[0023] In step 101, the pH value of the drilling waste fluid is adjusted to be slightly acidic.

[0024] In one embodiment of the present invention, using a pH regulator to adjust the pH value of the drilling waste flui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com