Co-used iron-carbon micro-electrolysis and photo degradation two-section perfluoro octanoic acid degradation method

An iron-carbon micro-electrolysis, perfluorooctanoic acid technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water pollutants, etc., can solve the problems of few applications, low degradation efficiency, slow speed, etc. simple conditional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

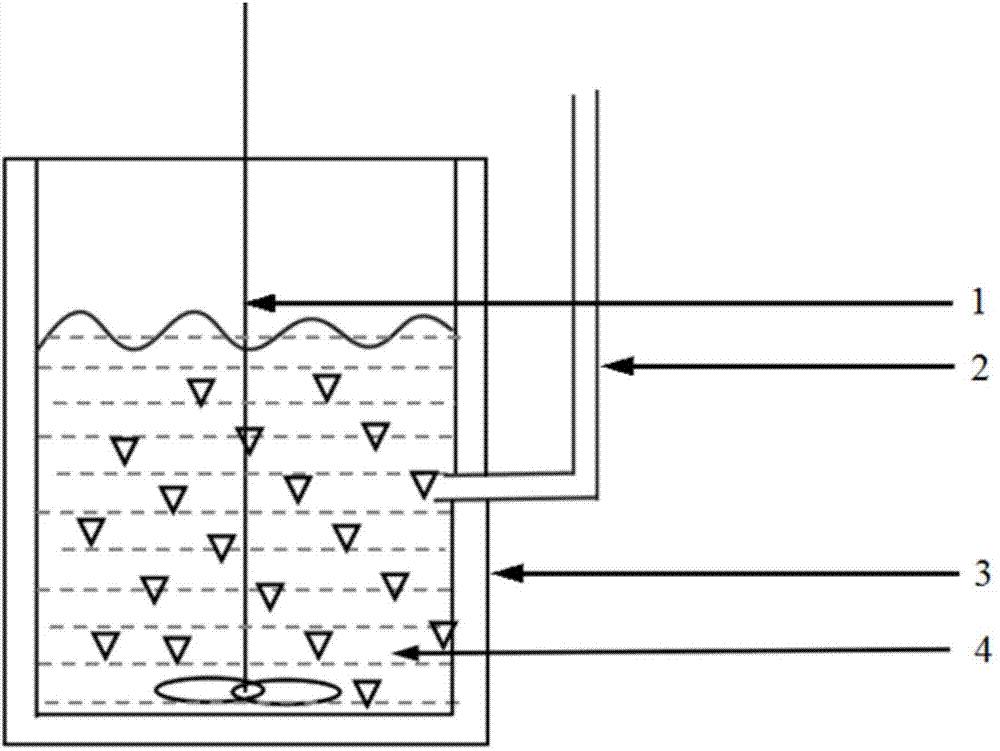

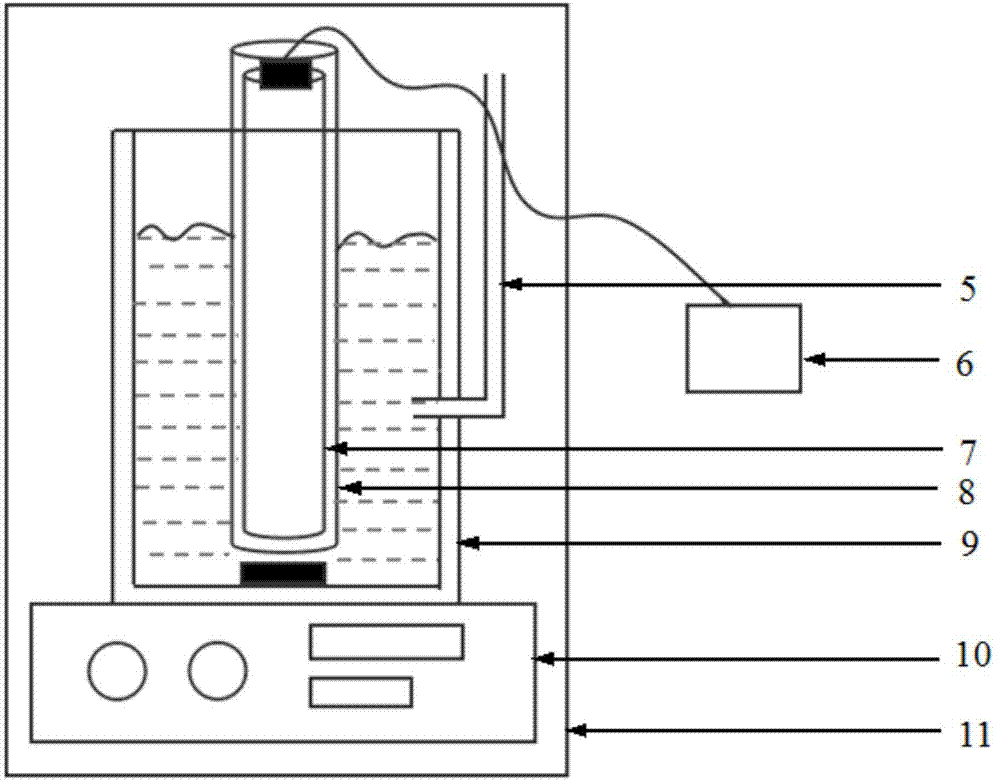

[0030] An iron-carbon micro-electrolysis-VUV / Fenton two-stage method for synergistically degrading perfluorooctanoic acid in water (iron-carbon micro-electrolysis), the method is composed of iron-carbon micro-electrolysis reaction and photodegradation reaction. The iron-carbon micro-electrolysis reaction device includes a stirring paddle 1 and a reactor 3 containing an aqueous solution containing perfluorooctanoic acid, and the stirring paddle 1 is placed in the middle of the reactor 3 . The reactor 3 is a cylindrical vessel made of polytetrafluoroethylene, on which a sampling tube 2 is arranged, and the aqueous solution 4 in the reactor 3 is composed of a perfluorooctanoic acid aqueous solution, activated carbon and iron powder. The photodegradation reaction device includes a timing constant temperature magnetic stirrer 10 and a photodegradation reactor 9, and the photodegradation reactor 9 is placed on the timing constant temperature magnetic stirrer 10. An ultraviolet lamp ...

Embodiment 2

[0040] The difference between this embodiment and embodiment 1 is:

[0041] Present embodiment does not carry out iron-carbon micro-electrolysis reaction, comprises the following steps:

[0042] a) Join the PFOA solution to be treated in the photodegradation reactor, turn on the magnetic stirrer, close the compartment 11, turn on the ultraviolet lamp 7 (the exterior is provided with an ultraviolet lamp lampshade 8), and react for 6 hours:

[0043] b) Turn off the UV lamp power supply 6, the reaction is finished, and the water is discharged, and the fluoride ion selective electrode is used to measure F - concentration to determine the defluorination rate.

[0044] After testing, the UV lamp alone has a defluorination rate of 39.89% for PFOA, indicating that the UV lamp has a certain photolysis effect on PFOA.

Embodiment 3

[0046] The difference between this embodiment and embodiment 1 is:

[0047] The method for utilizing the device to degrade PFOA in water comprises the steps:

[0048] a) Carry out pretreatment to activated carbon, take quantitative activated carbon, soak in the solution to be treated for 24 hours, rinse with ultrapure water, and dry for subsequent use;

[0049]b) Add the PFOA solution to be treated into the reactor, add pretreated activated carbon 12.5g / L and iron powder 7.5g / L at the same time, adjust the pH of the reaction solution to 3.0 with 0.1mol / L NaOH and HCl; open stirring paddle, react for 1 hour;

[0050] c) Turn off the stirring paddle, the iron-carbon micro-electrolysis reaction is completed, filter the water, inject it into the photodegradation reactor, adjust the pH to 3.0 with 0.1mol / L NaOH and HCl, turn on the ultraviolet power supply, and react for 6 hours;

[0051] d) Turn off the ultraviolet light power supply, the reaction is completed, and the water is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com