Sauce and chilli powder, preparation method thereof and seasoning powder

The technology of sauce chili powder and seasoning powder is applied in the field of condiments, which can solve the problems of inconvenient transportation, large amount of seasoning addition, and difficulty in long-term preservation of chili sauce, and achieves the effects of convenient transportation, small amount of seasoning addition, and low moisture content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a kind of preparation method of sauce pepper powder, comprises the following steps:

[0024] Crush and sieve the chili peppers, mix and ferment with the sauce and distilled wine, and then spray dry to obtain the sauce pepper powder;

[0025] The sauce is the sauce obtained by centrifuging fermented soybean sauce.

[0026] In the invention, firstly, the chili is crushed and sieved to obtain chili powder. In the present invention, the pepper is preferably Xiangyan No. 5 pepper. The fruit of the Xiangyan No. 5 chili has a soft flesh and a spicy but not strong taste. Using Xiangyan No. 5 pepper as raw material to prepare sauce pepper powder can improve the product's spicy and overall flavor. The pulverization of the present invention is preferably carried out in a pulverizer, and the pulverized pepper is passed through an 80-mesh sieve to obtain chili powder.

[0027] The paprika is mixed with the sauce and distilled spirits to obtain a mixture. ...

Embodiment 1

[0050] The preparation of embodiment 1 sauce

[0051] 1. Select high-quality soybeans that are fully mature, full and uniform in grain, fresh, high in protein, free from insects, mildew, deterioration and impurities.

[0052] 2. Weigh the soybeans into the pool, add water to submerge the beans by 20-30cm, control the water temperature below 40°C, and soak for 4-5 hours until more than 90% of the beans have no wrinkles, and the moisture content is preferably about 45%.

[0053] 3. Use a rotary high-pressure cooking pot. After draining the soaked soybeans, they are sent to the rotary pot through the elevator, and the steam cooking is turned on after the cover is added. When the temperature in the tank reaches 90 ° C, the pressure in the tank is exhausted to zero. Close the exhaust valve, open the steam inlet valve, and when the pressure in the tank reaches 0.1MPa, keep it for 50-60 minutes. The steamed soybeans are required to have uniform color (purple red), no hard core, no ...

Embodiment 2

[0066] Wash and remove impurities from the raw material of Xiangyan No. 5 chili pepper, crush and sieve, add sauce ingredients, wherein 40kg of the sauce prepared in Example 1 and 4kg of distilled wine are added for every 100kg of chili pepper, and the rice brewing alcohol of the distilled wine is 50% . Put the above raw materials in a stainless steel fermentation tank to seal, ferment for 5 days at a temperature of 25°C, and spray dry the fermented semi-finished product. The inlet temperature of the spray dryer is 180-210°C, and the outlet temperature is 100-110°C. Carry out bottling after pulverizing with 100 mesh particle pulverizers then, obtain the product moisture content 13%, salinity 21%, the pickled pepper dry powder of amino acid state nitrogen 0.4g / 100g.

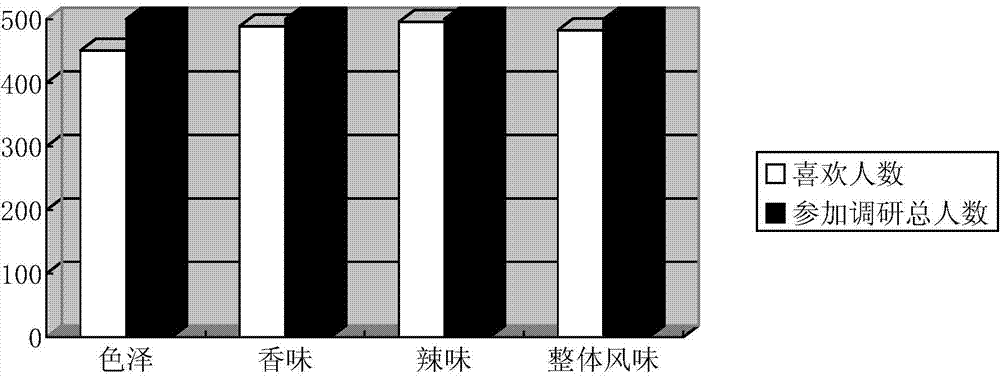

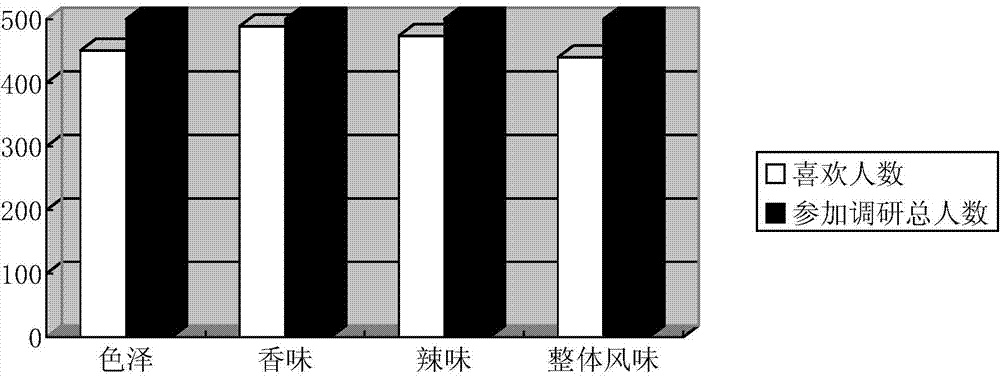

[0067] The pickled pepper powder was tested for sensory indicators, physical and chemical indicators and microbial indicators, and the results are shown in Table 1, Table 2 and Table 3. Table 1 is the test result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com