Banana and pea starch food and production method thereof

A technology of pea starch and banana, which is applied in the field of food processing, can solve the problems of single taste, poor food acceptability, and insufficient chewiness, and achieve the effects of low calorific value, good anti-caries properties, and sufficient chewiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

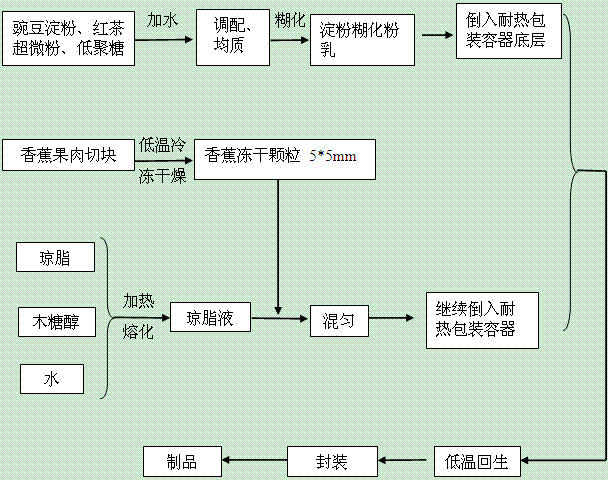

Image

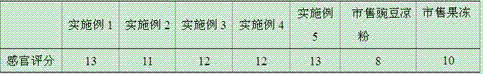

Examples

Embodiment 1

[0030] The pea starch described in this implementation case is prepared by the traditional Physalis method, oligosaccharides and xylitol are commercially available, and black tea superfine powder and banana freeze-dried granules are all self-made.

[0031] Pretreatment: black tea powder is frozen and ultrafinely pulverized to obtain ultrafine powder with a fineness of 200-300 mesh;

[0032] Freeze-dried banana particles are 5*5mm particles obtained by freeze-drying and pulverizing banana meat;

[0033] Agar solution: Take 8 g of agar, 0.3 g of xylitol and water, heat and melt to prepare an agar solution with a concentration of 8 mg / ml.

[0034] Process steps of the present invention, such as figure 1 Shown:

[0035] (1) Take 4g of pea starch, 0.2g of black tea superfine powder, 0.7g of maltose oligosaccharide, and 0.5g of xylitol, add an appropriate amount of water, stir evenly, and then enter the colloid mill and fully mix for 5 minutes to obtain a solid content of ...

Embodiment 2

[0040] Pretreatment: same as embodiment 1, no more details here.

[0041] Process step of the present invention:

[0042] (1) Take 4.5g of pea starch, 0.3g of black tea superfine powder, 0.8g of a mixture of malto-oligosaccharide and fructo-oligosaccharide, and 0.5g of xylitol, add an appropriate amount of water, stir evenly, and then enter the colloid mill for thorough mixing treatment 4 Minutes to obtain mixed powdered milk with a solid content of 14wt.%, gelatinized in a boiling water bath at 95°C for 7 minutes, and pour the obtained gelatinized powdered milk into a transparent glass container;

[0043] (2) Take 4.5g of banana freeze-dried granules, add them to 40ml of agar liquid, and pour them into the surface of the gelatinized milk powder in the transparent glass container described in step (1);

[0044] (3) Low-temperature retrogradation treatment at 4°C for 8 hours;

[0045] (4) After packaging, the banana and pea food with high content of resistant starch is ...

Embodiment 3

[0047] Pretreatment: same as embodiment 1, no more details here.

[0048] Agar liquid: Take 8 g of agar, 0.5 g of xylitol and water, heat and melt to prepare an agar liquid with a concentration of 8 mg / ml.

[0049] Process step of the present invention:

[0050] (1) Take 5g of pea starch, 0.4g of superfine black tea powder, 0.9g of a mixture of maltooligosaccharide and xylooligosaccharide, and 0.4g of xylitol, add an appropriate amount of water, stir evenly, and then enter the colloid mill for thorough mixing treatment 3 Minutes to obtain mixed powder milk with a solid content of 15wt.%, gelatinization in a boiling water bath at 100°C for 10 minutes, and quickly pour the obtained gelatinized powder milk into a transparent glass container;

[0051] (2) Take 4.5g of banana freeze-dried granules, add them to 45ml of agar liquid, and pour them into the surface of the gelatinized milk powder in the transparent glass container described in step (1);

[0052] (3) Low-temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com