Preparation method of S/C composite material used in positive pole of Li-S battery

A technology of carbon composite materials and lithium-sulfur batteries, which is applied in battery electrodes, circuits, electrical components, etc., can solve problems such as troublesome gas swelling, suppress the loss of active materials, improve cycle stability and rate performance, and overcome sulfur distribution uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of a sulfur / carbon composite material for a positive electrode of a lithium-sulfur battery, the steps are as follows:

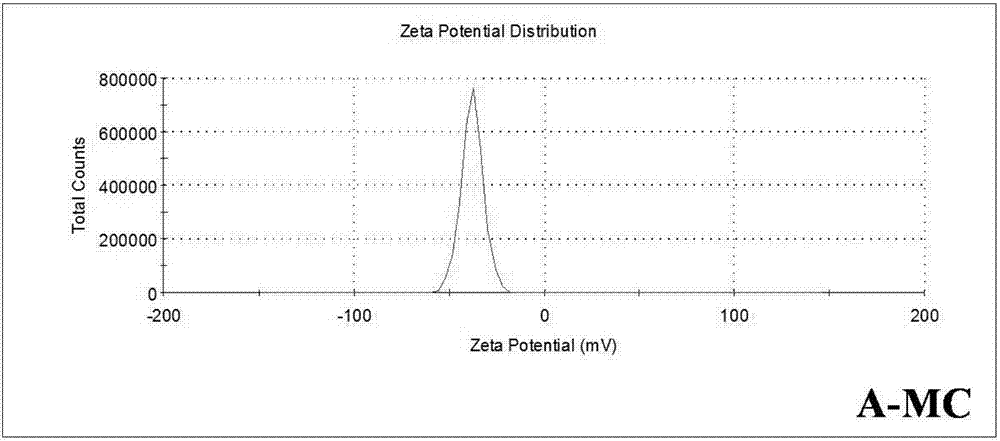

[0032] (1) Acid treatment of mesoporous carbon: 0.25 g of mesoporous carbon was added to a round-bottomed flask, and then 15 mL of concentrated sulfuric acid (18M) and 5 mL of concentrated nitric acid (16M) were sequentially added. The reaction was stirred at 50 °C for 5 h, after cooling, suction filtration, washed with water until neutral, and vacuum dried at 80 °C, and the obtained sample was recorded as A-MC.

[0033] (2) Preparation of sulfur / mesoporous carbon composite material: After mixing and grinding the A-MC obtained in step (1) and sulfur in a mass ratio of 3:2, put it into a closed 10 mL reaction kettle filled with argon. , heat treatment at 180 °C for 12 h in a muffle furnace to obtain the sulfur / mesoporous carbon composite material, denoted as A-MCS.

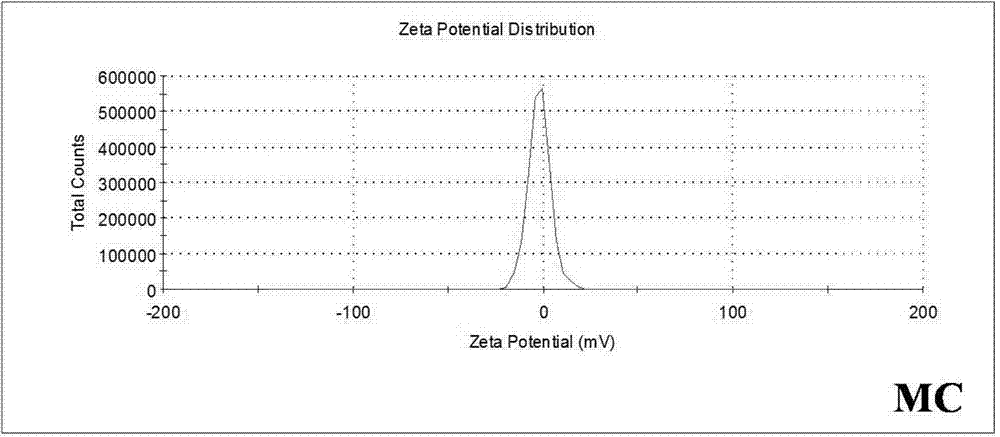

[0034] As a control, mesoporous carbon (denoted as MC) was direct...

Embodiment 2

[0043] A preparation method of a sulfur / carbon composite material for a positive electrode of a lithium-sulfur battery, the steps are as follows:

[0044] (1) Acid treatment of carbon black: add 0.25 g of carbon black to a round-bottomed flask, and then add 15 mL of concentrated sulfuric acid and 5 mL of concentrated nitric acid in sequence. The reaction was stirred at 50 °C for 5 h, after cooling, suction filtered, washed with water until neutral, and dried under vacuum at 80 °C.

[0045] (2) preparation of sulfur / carbon black composite material: after the carbon black obtained in step (1) and sulfur are mixed and ground in a mass ratio of 3:2, put into a closed 10mL reactor filled with argon, Heat treatment at 180° C. for 12 h in a muffle furnace to obtain the sulfur / carbon black composite material.

[0046] The prepared sulfur / carbon black composite material was tested and characterized similarly to Example 1, and the conclusion was basically similar to that of Example 1. ...

Embodiment 3

[0048] A preparation method of a sulfur / carbon composite material for a positive electrode of a lithium-sulfur battery, the steps are as follows:

[0049] (1) Acid treatment of carbon nanotubes: 0.25 g of carbon nanotubes were added to a round-bottomed flask, and then 15 mL of concentrated sulfuric acid and 5 mL of concentrated nitric acid were sequentially added. The reaction was stirred at 50 °C for 5 h, after cooling, suction filtered, washed with water until neutral, and dried under vacuum at 80 °C.

[0050] (2) Preparation of sulfur / carbon nanotube composite material: After mixing and grinding the carbon nanotubes obtained in step (1) and sulfur in a mass ratio of 3:2, put them into a closed 10mL reaction kettle filled with argon. , heat treatment in a muffle furnace at 180° C. for 12 h to obtain the sulfur / carbon nanotube composite material.

[0051] The prepared sulfur / carbon nanotube composites were tested and characterized similarly to Example 1, and the conclusions ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com