Ballastless track board disengaging nondestructive detection method based on elastic waves

A ballastless track and non-destructive testing technology, applied in the field of safety testing, can solve problems such as difficult frequency domain analysis, shallow detection depth, and low test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

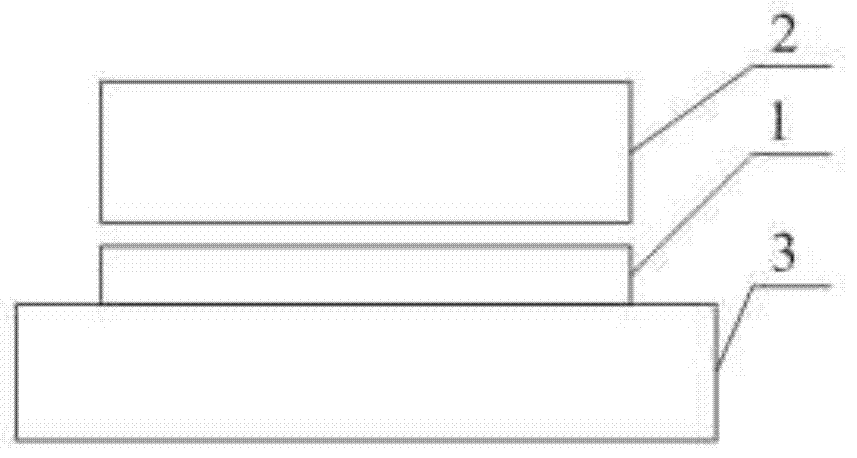

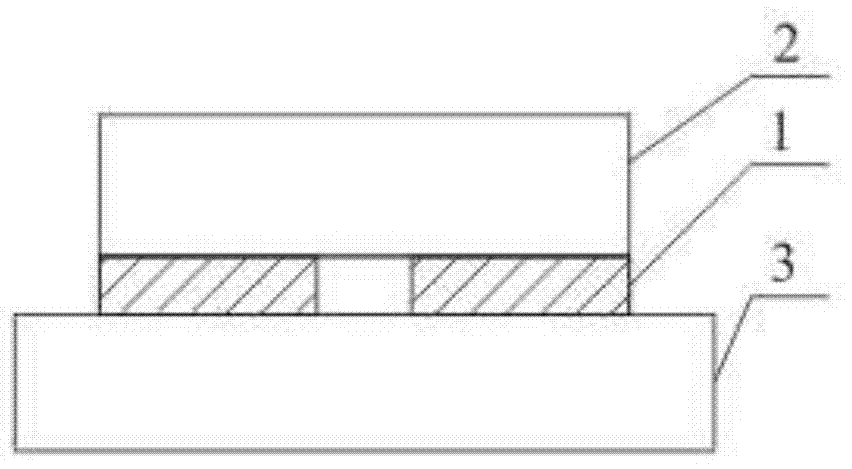

[0080] In this embodiment, the present invention is described by taking CRTS II type ballastless track slab (hereinafter referred to as Type II) and CRTS III type ballastless track slab (hereinafter referred to as Type III) as examples. Naturally, the present invention can also be used for void detection of other ballastless track slabs with similar structures.

[0081] Parameters of various ballastless track slab filling layers

[0082]

[0083] A non-destructive detection method for voiding of ballastless track slabs based on elastic waves, including the following steps:

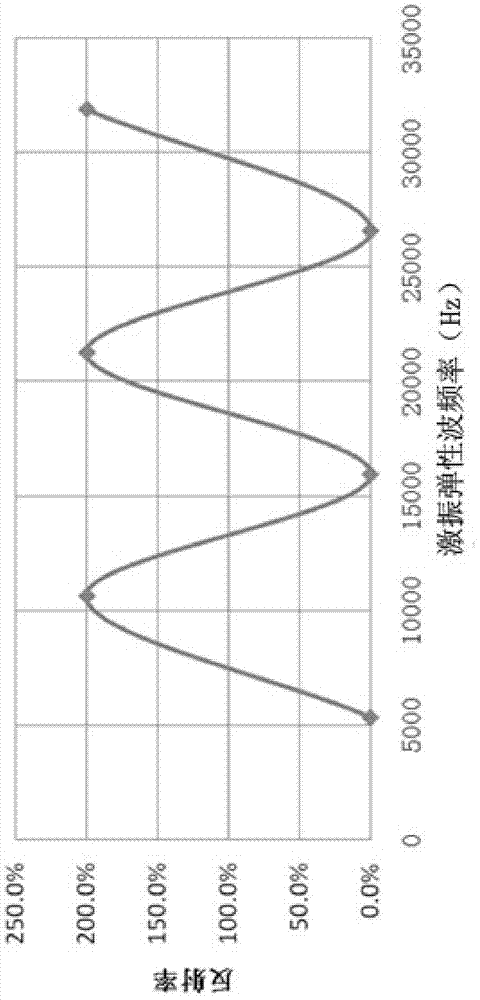

[0084] A. Determine the functional relationship between the excitation elastic wave frequency and the elastic wave reflectivity of the void surface;

[0085] B. Determine the functional relationship between the excitation elastic wave frequency and the elastic wave reflectivity of the filling layer;

[0086] C. According to the functional relationship obtained in step A and step B, draw the frequency ...

Embodiment 2

[0167] The method for detecting void rate of ballastless track slab based on elastic wave includes the following steps:

[0168] A. Divide the grid on the top plate, each grid is a measuring point;

[0169] B. adopt the method described in embodiment 1, detect each measuring point respectively;

[0170] C. Calculate the proportion of empty measuring points to all measuring points, which is the emptying rate of ballastless track slab.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com