Organochlorine content determination method

A determination method and organochlorine technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of large errors, complicated operation processes, low instrument sensitivity, etc., to improve production efficiency and economic benefits, eliminate test errors, and operate easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The content of residual dichloroethane in water-soluble chemical products is determined according to the following steps:

[0023] a. Start the gas chromatograph:

[0024] Turn on the hydrogen generator (flow 0.3MPa), air cylinder (flow 0.5MPa), nitrogen cylinder (flow 0.5MPa), turn on the host computer, wait for the gas path to stabilize, turn on the headspace and gas chromatograph switch, and enter the LAB operation interface. Set the instrument operating parameters as follows:

[0025] Nitrogen flow rate: 26.2mL / min; hydrogen flow rate: 30 mL / min; air flow rate: 400 mL / min; column oven temperature: 80°C; injection port split ratio: 1:150; FID detector temperature: 300°C.

[0026] b. Standard solution preparation:

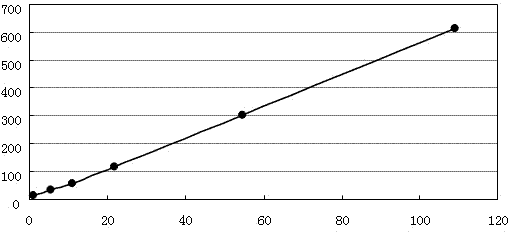

[0027] Weigh 0.1g (accurate to 0.001g) dichloroethane sample, dilute to 1L with distilled water, as the mother liquor, accurately pipette 1mL, 5 mL, 10 mL, 20 mL, 50 mL of mother liquor, and dilute to 100 mL as the standard solution, then pipette 5 mL o...

Embodiment 2

[0035] The residual dichloromethane content in water-soluble chemical products is carried out according to the following steps:

[0036] a. Start the gas chromatograph:

[0037] Turn on the hydrogen generator (flow 0.3MPa), air cylinder (flow 0.5MPa), nitrogen cylinder (flow 0.5MPa), turn on the host computer, wait for the gas path to stabilize, turn on the headspace and gas chromatograph switch, and enter the LAB operation interface. Set the operating parameters of the instrument as follows: nitrogen flow rate: 26.2mL / min; hydrogen flow rate: 30 mL / min; air flow rate: 400 mL / min; column oven temperature: 60°C; inlet split ratio: 1:150; FID detector Temperature: 300°C.

[0038] b. Standard solution preparation:

[0039] Weigh 0.1g (accurate to 0.001g) of dichloromethane sample, dilute to 1L with distilled water, as the mother liquor, accurately pipette 1mL, 5 mL, 10 mL, 20 mL, 50 mL mother liquor, and dilute to 100 mL with distilled water mL as the standard solution, pipett...

Embodiment 3

[0047] The content of residual dichloroethane in oil-soluble chemical products is determined according to the following steps:

[0048] a. Start the gas chromatograph:

[0049] Turn on the hydrogen generator (flow 0.3MPa), air cylinder (flow 0.5MPa), nitrogen cylinder (flow 0.5MPa), turn on the host computer, wait for the gas path to stabilize, turn on the headspace and gas chromatograph switch, and enter the LAB operation interface. Set the instrument operating parameters as follows:

[0050] Nitrogen flow rate: 26.2mL / min; hydrogen flow rate: 30 mL / min; air flow rate: 400 mL / min; column oven temperature: 80°C; injection port split ratio: 1:150; FID detector temperature: 300°C.

[0051] b. Standard solution preparation:

[0052] Weigh 0.1g (accurate to 0.001g) of dichloroethane sample, dilute to 1L with dimethyl sulfoxide, and use it as mother liquor, accurately pipette 1mL, 5 mL, 10 mL, 20 mL, 50 mL mother liquor respectively, and use Dimethyl sulfoxide was adjusted to 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com