A laboratory flue gas treatment evaluation research platform

A flue gas treatment and laboratory technology, applied in the direction of measuring devices, suspension and porous material analysis, scientific instruments, etc., can solve the problem of not being able to study the influence of the filter bag of the bag filter (dust removal efficiency, service life, uneven dust mixing in the pipeline, etc.) Problems such as inability to carry out high temperature experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

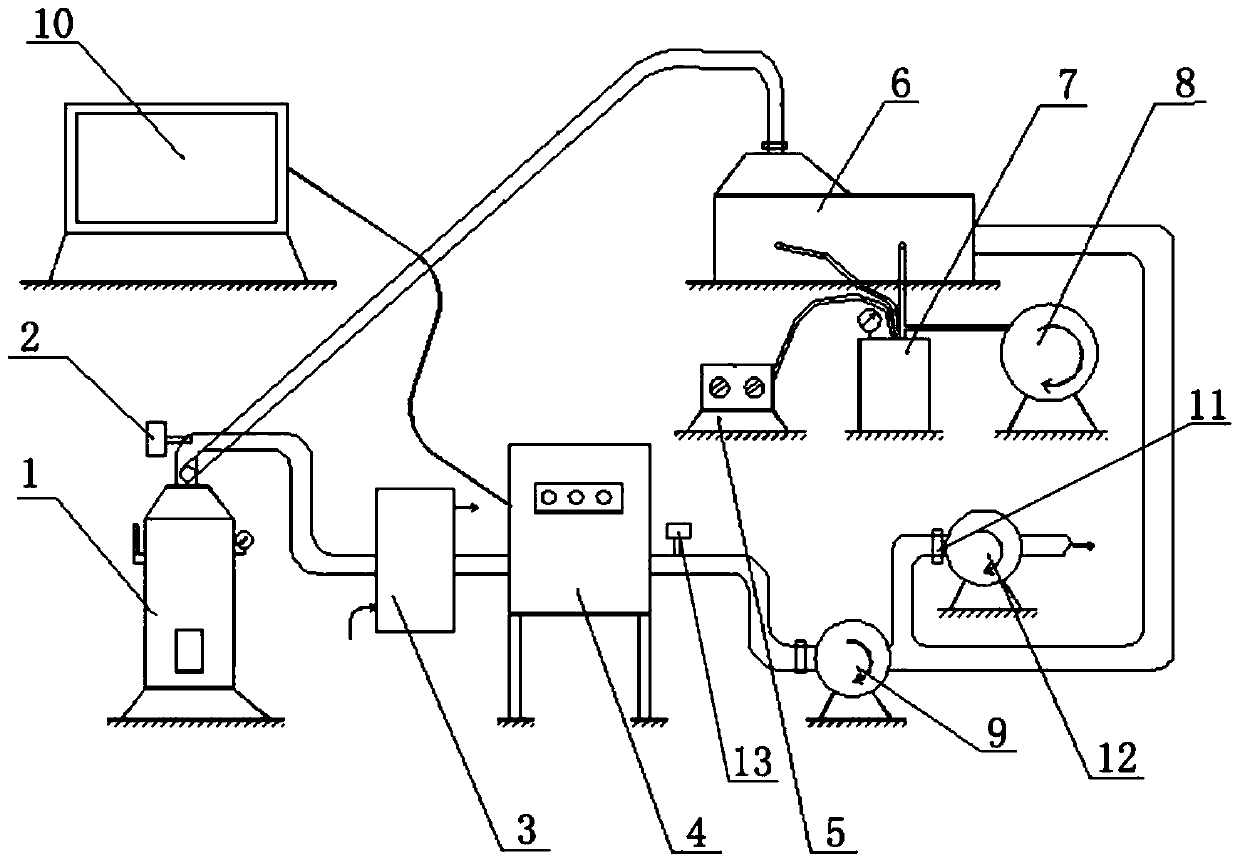

[0015] see figure 1 , the laboratory flue gas treatment evaluation research platform of the embodiment of the present invention, including coal-fired boiler 1, powder sprayer 7, bag filter 4, automatic online detection system 10 for testing the dust removal efficiency of bag filter 4, can make dust Evenly distributed and heated heating diffusion container 6, cooler 3 and control system 5 for controlling the powder sprayer 7; the control system 5 can adjust the powder injection pressure of the powder sprayer 7, and the powder sprayer 7 can It is used when the flue gas produced by the coal-fired boiler is insufficient. The coal-fired boiler 1 is sequentially connected to the cooler 3 and the bag filter 4 through the flue gas discharge pipe. The dust detector for detecting the dust content is installed on the flue gas discharge pipe of the coal-fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com