A rice polishing residue processing and dedusting device

A residue and rice technology, which is applied in the field of agricultural product processing, can solve problems such as pipeline pressure burden, low settlement efficiency, and high gas pressure at the warehouse port, and achieve the effects of reducing the pressure at the warehouse entrance, improving the quality of rice, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

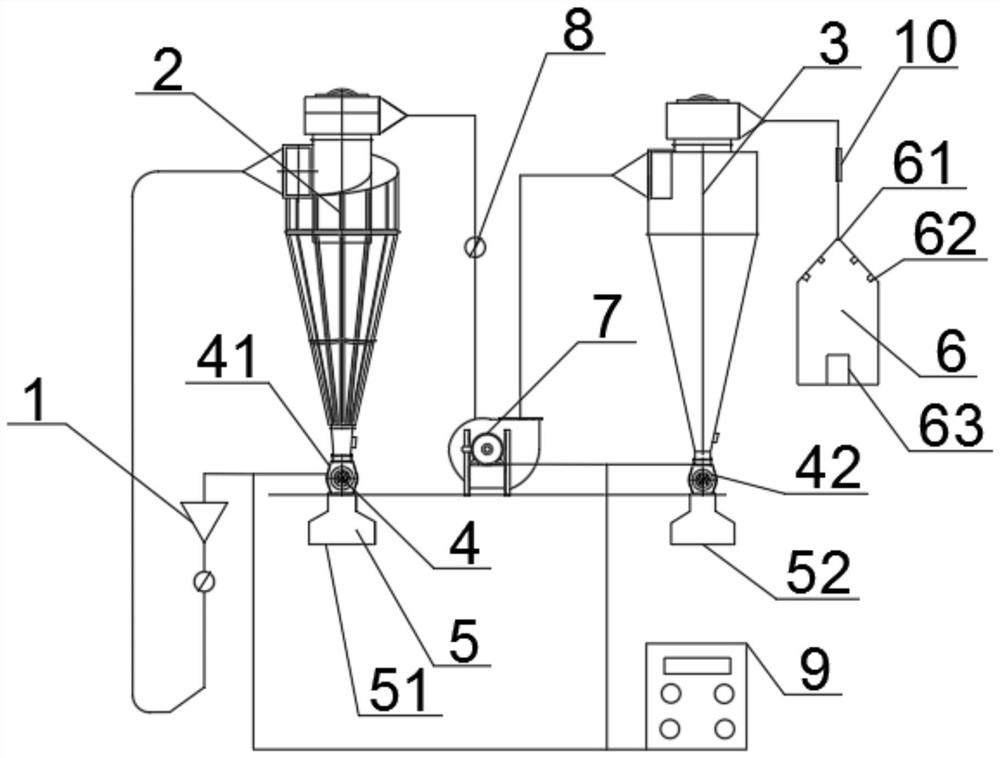

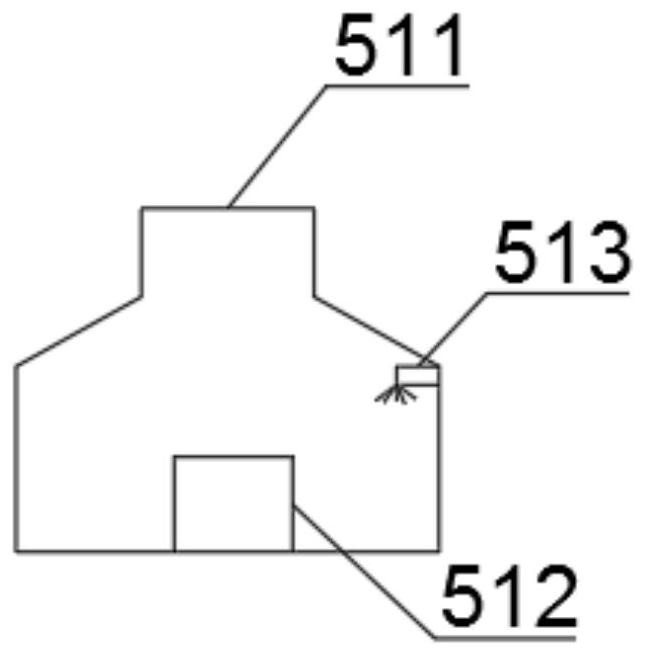

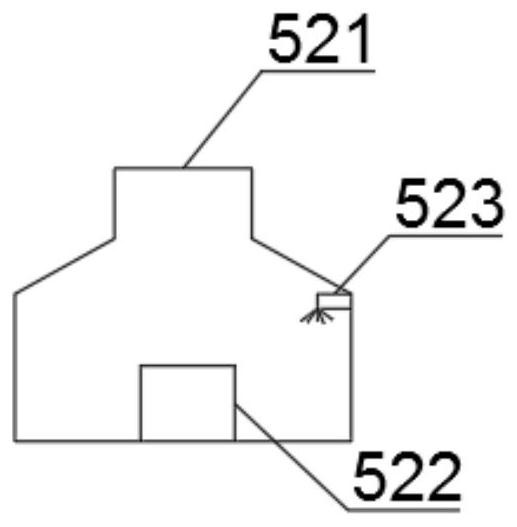

[0022] The technical scheme of a rice polishing residue treatment and dust removal device provided by the present invention will be further described below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention and implement it.

[0023] see figure 1 , figure 2 , image 3 , Figure 4 , the present invention provides a kind of rice polishing residue processing dust removal device, comprising rice polishing machine 1, polishing residue processing dust removal machine 2, secondary dust removal processing machine 3, straight-through air lock group 4, polishing powder settlement processing bin group 5. Waste dust residue treatment room 6, ventilation fan 7, air regulating plate group 8, operation console 9, polishing powder settlement treatment bin group 5 includes polishing powder settlement treatment bin 1 51, polishing powder sedimentation processing bin 2 52, rice The polishing machine 1 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com