Segment transforming process for well-completion acid fracturing of open-hole horizontal well of oil gas well

A segmented reconstruction and horizontal well technology, which is applied in wellbore/well components, production fluid, earthwork drilling and production, etc. It can solve the problems of inability to construct horizontal wells in segmented acid fracturing, non-full diameter with steps, long introduction period, etc. problem, to achieve the effect of high reliability, strong corrosion resistance, and many stages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

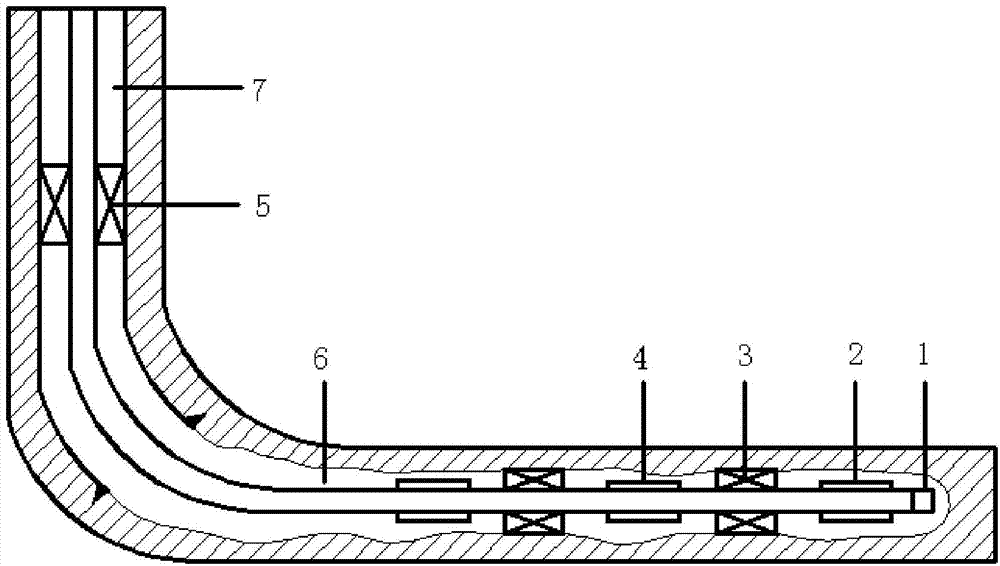

[0023] Embodiment 1, a kind of segmental transformation process for oil and gas well open-hole horizontal well completion acid fracturing, such as figure 1 As shown, the process consists of the following steps:

[0024] 1. Pipe string design: Run completion tools in the 6-5 / 8 inch horizontal open hole section 6 to divide the reservoir into 6 sections. The completion tools include five 158mm open hole packers 3 and one 142mm Ball-pitching screen 2, five 142mm pressure control screens 4 and one 150mm full bore completion check valve 1;

[0025] 2. Running of the pipe string: pass the open hole section 6 of the horizontal well that needs to be acid fractured through the first, second, and fourth wells, and connect the well to normal, ensuring that the maximum dogleg degree is lower than 6.8 ° / 30m; before the four-support simulated drilling, high-quality mud is placed in the open hole section, and the performance must meet the following indicators: specific gravity not exceeding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com