Novel nano electrostatic siro-spinning method

A siro spinning, nano-level technology, applied in the field of nano-level electrostatic siro spinning, can solve the problems of low manufacturing efficiency and limited application fields, and achieve the effects of improving manufacturing efficiency, improving utilization rate and good evenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

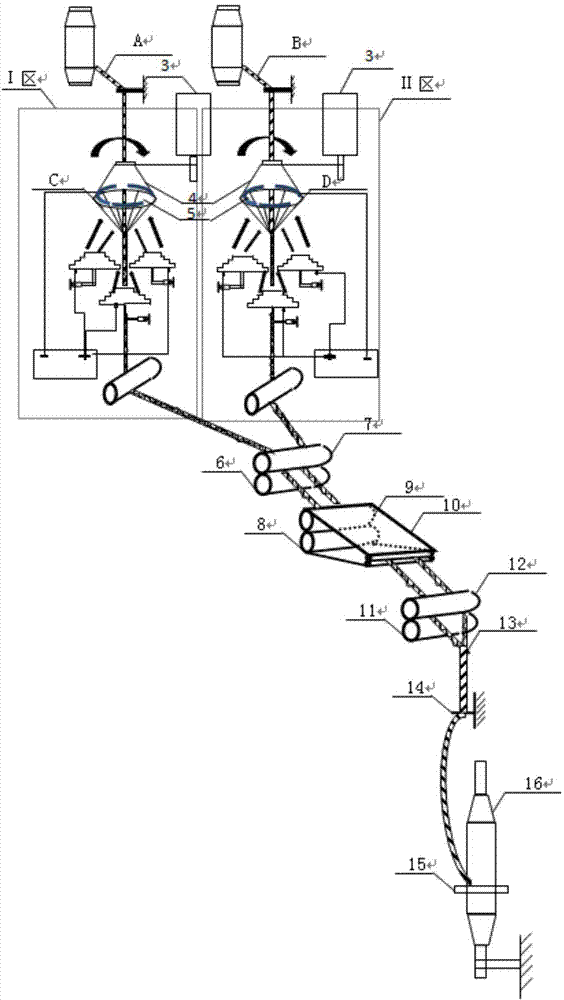

[0021] See attached figure 1 , the staple fiber rovings A and B unwound from two roving bobbins are fed in parallel into two electrospinning sections I and II between the feed roller and the roving hanger, in these two sections, both There is a motor 3 rotating at a certain speed to drive the horn-shaped receiver 4 for collecting nanofibers. The two horn-shaped receivers rotate separately to form an air flow. On the receiving ring 5 of the receiver, the deposited nanofiber bundle C is driven by the airflow to merge with the roving A flowing through the horn-shaped receiver; the nanofiber bundle D is merged with the roving B flowing through the horn-shaped receiver The two rovings drive the nanofibers into the rear drafting and twisting device in parallel, including rear roller 6, rear top roller 7, middle roller 8, middle top roller 9, apron 10, front roller 11, front top roller 12 After the two multi-component composite yarns are exported by the front roller, they are combin...

Embodiment 2

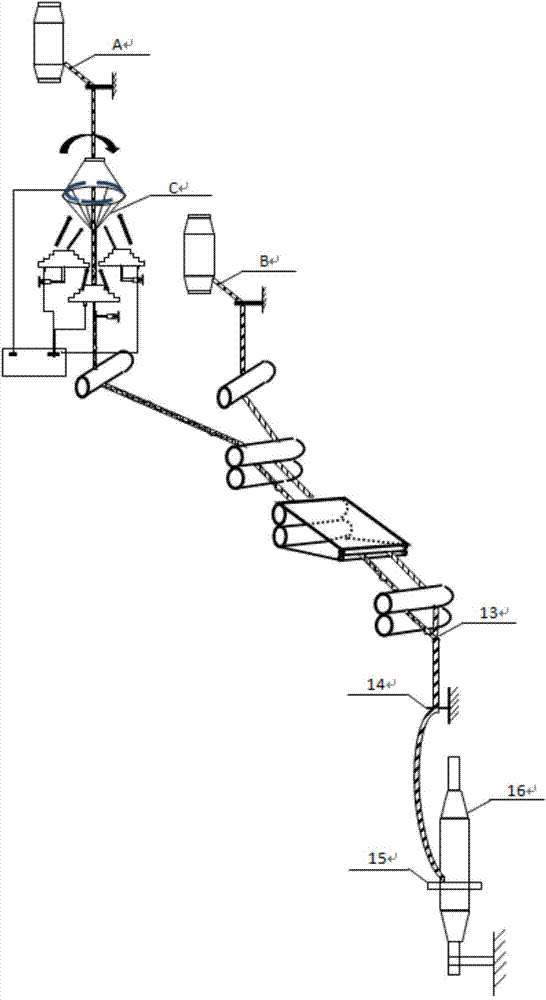

[0025] Such as Figure 2-Figure 3 As shown, the staple fiber rovings A and B unwound from two roving bobbins are fed in parallel to two electrospinning sections between the feed roller and the roving hanger. In this section, there are A motor rotating at a certain speed drives the horn-shaped receivers used for collecting nanofibers, and the two horn-shaped receivers rotate separately to form an air flow, and the nanofiber C is helically deposited on the receiving rings of the two horn-shaped receivers driven by the electric field force , the deposited nanofiber bundle C is driven by the airflow to merge with the roving A flowing through the horn-shaped receiver; the A roving drives the nanofibers into the rear drafting and twisting device in parallel, while the roving B directly enters the rear area Drafting and twisting device, after the two composite yarns of different components are exported by the front roller, they are merged at the joint point 13 and then twisted again,...

Embodiment 3

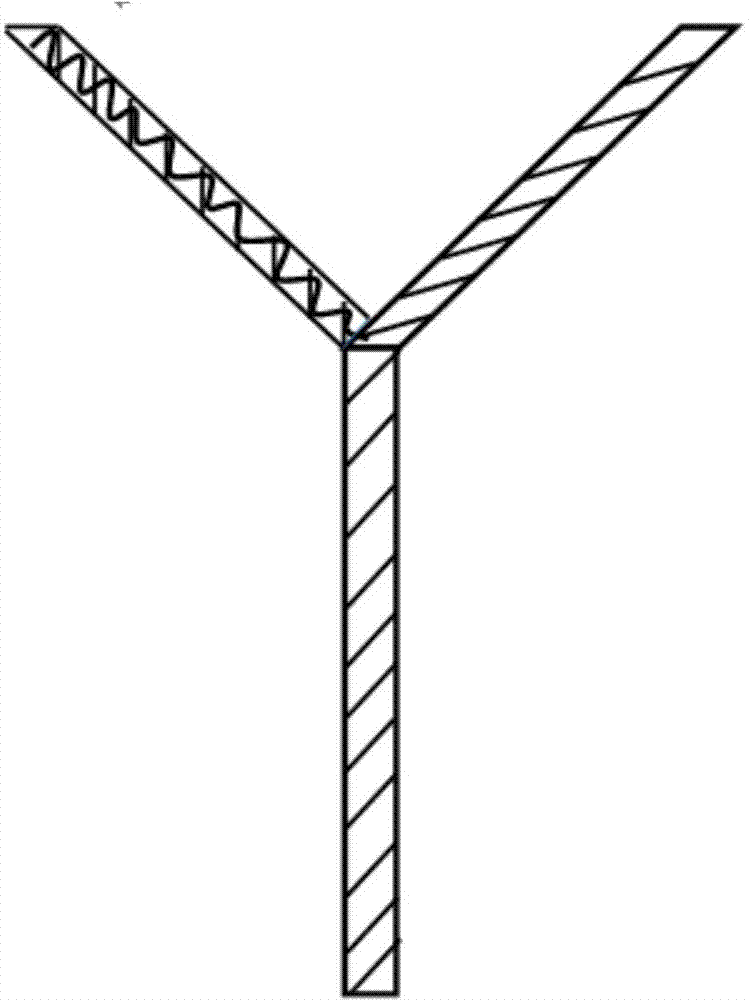

[0027] Such as Figure 4 As shown, the two strands are fed from the back roller of Siro spinning, pass through the middle roller, and the front roller is drafted and combined for output. An electrospinning device is installed between the front roller and the yarn guide hook. The electrospinning device is composed of a horn-shaped receiver, a material barrel, a pyramid-shaped spinneret, an electrostatic generator, a motor, and a chain. Driven by the electric field force, the fibers are spirally deposited on the receiver of the horn-shaped receiver. Driven by the airflow, the deposited nanofiber bundles are merged again with the merged roving flowing through the horn-shaped receiver, and passed through the yarn guide hook and steel wire. The coil is wound on the spun yarn tube, and the outer layer of the core-spun yarn that is finally drawn out contains nanofibers, which increases the hygroscopicity, oil absorption and filtration performance of the yarn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com