Production method of calcium superphosphate

A production method, general calcium technology, applied in the field of high-magnesium general calcium production, can solve problems such as economic loss and phosphorus value not being reflected, and achieve the effects of low production cost, increased added value, and huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

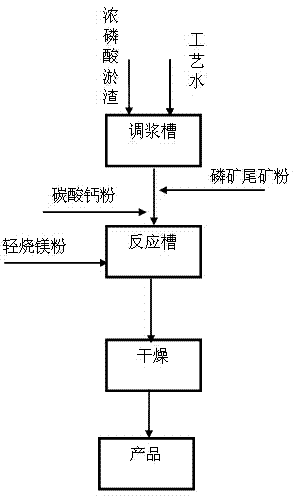

Method used

Image

Examples

Embodiment 1

[0022] Get 150g concentrated phosphoric acid sludge, its total P 2 o 5 21.2%, water soluble P 2 o 5 is 18.3%, add water to adjust the slurry concentration to 25%, add 65g of phosphate ore flotation tailings, the P in the tailings 2 o 5 8.2% magnesium oxide and 15.1% magnesium oxide. After stirring evenly, add 20g magnesium oxide and 20g calcium powder. After reacting for 15 minutes, dry the materials to obtain high-magnesium general calcium products. After analysis, the main components of the product are: total P 2 o 5 The content of free acid is 0, the content of magnesium oxide is 10.4%, and the content of sulfate is 10.3%. The product quality meets the requirements of high magnesium general calcium in the New Zealand market.

Embodiment 2

[0024] Get 150g concentrated phosphoric acid sludge, its total P 2 o 5 21.2%, water soluble P 2 o 5 is 18.3%, add water to adjust the slurry concentration to 25%, add 90g phosphate ore flotation tailings, the P in the tailings 2 o 5 8.2% magnesium oxide and 15.1% magnesium oxide. After stirring evenly, add 25g magnesium oxide and 20g calcium powder. After reacting for 20 minutes, dry the materials to obtain high-magnesium general calcium products. After analysis, the main components of the product are: total P 2 o 5 The content of free acid is 15.8%, the content of free acid is 0, the content of magnesium oxide is 12.7%, and the content of sulfate radical is 9.3%. The product quality meets the requirements of high magnesium general calcium in the New Zealand market.

Embodiment 3

[0026] Get 150g concentrated phosphoric acid sludge, its total P 2 o 5 21.2%, water soluble P 2 o 5 is 18.3%, add water to adjust the slurry concentration to 25%, add 70g of phosphate ore flotation tailings, the P in the tailings 2 o 5 It is 8.2% and magnesium oxide is 15.1%. After stirring evenly, add 15g of magnesium oxide and 25g of calcium powder. After reacting for 60 minutes, the materials are dried to obtain high-magnesium general calcium products. After analysis, the main components of the product are: total P 2 o 5 The content of free acid is 0, the content of magnesium oxide is 11.3%, and the content of sulfate is 10.7%. The product quality meets the requirements of high magnesium general calcium in the New Zealand market.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com