Seat backrest skeleton of intercity bus

A technology for seat backs and long-distance buses, which is applied to seat frames and other directions, can solve the problems of large groove width and loss of honeycomb support, etc., and achieves the effects of simple structure, improved overall stress, and meeting strength requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

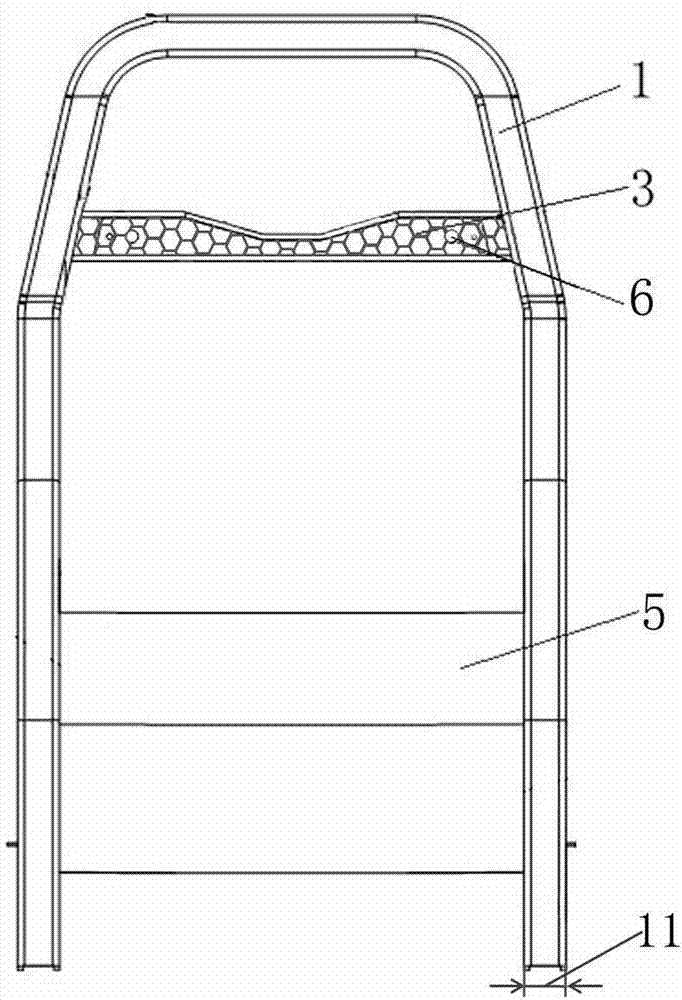

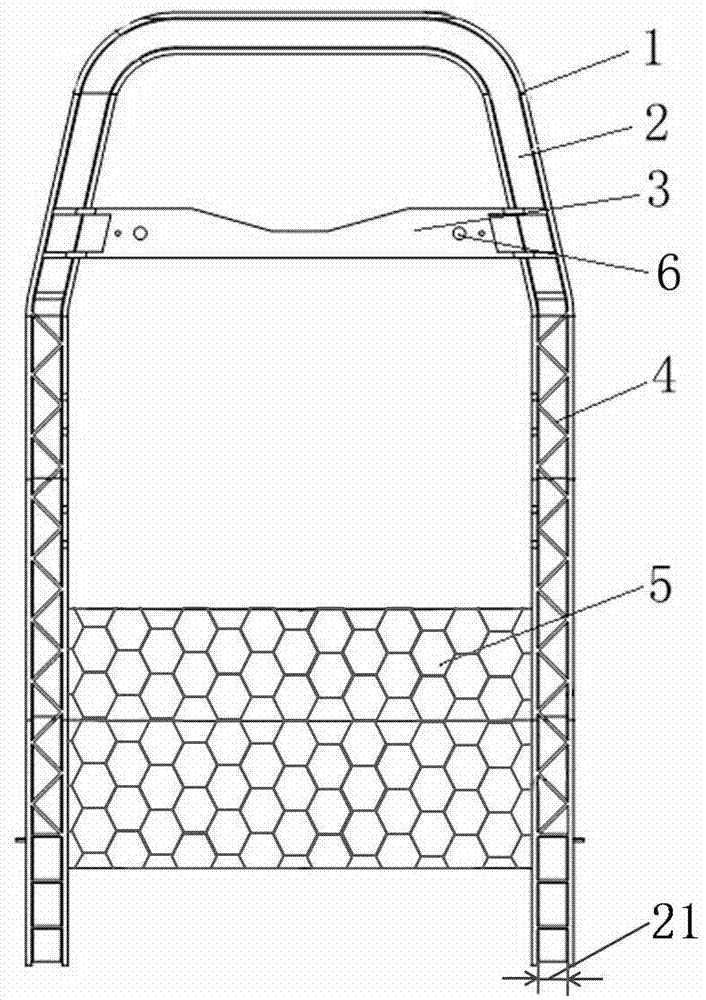

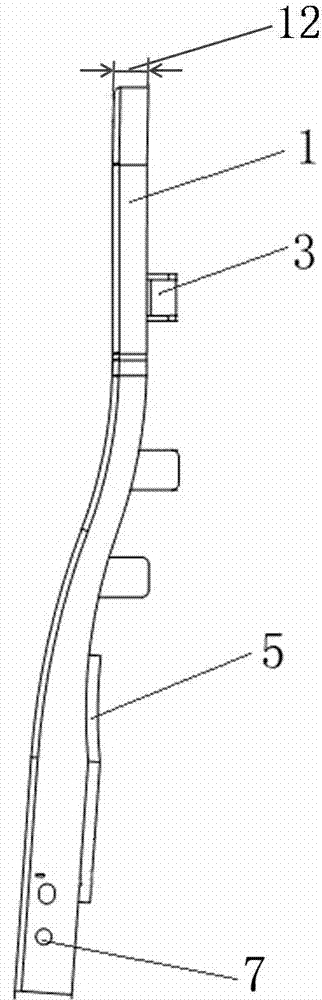

[0019] Such as figure 1 , 3 As shown, a long-distance bus seat back frame includes a door frame-shaped frame 1 integrally formed with thermoplastic composite materials, the frame 1 is a U-shaped groove structure, the width 11 of the frame 1 is 20-40 mm, and the thickness 12 of the frame 1 is 25-40 mm. 50 mm, the width 21 of the U-shaped groove 2 is 15-35 mm, and the thickness 12 of the skeleton 1 is greater than or equal to the width 21 of the U-shaped groove 2 . The size and structure of the headrest and backrest of the seat back frame are optimized. Since the groove width is moderate and the thickness of the frame is greater than the width of the U-shaped groove, the overall stress of the back frame has been significantly improved, avoiding the The U-shaped groove of the groove is too wide, causing the skeleton to be twisted and deformed, resulting in uneven force.

[0020] Corrugated reinforcing ribs 4 are arranged in the U-shaped groove 2, and the corrugated reinforcing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com