Preparation method of graphene microsphere biological separation medium with controllable particle size

A technology of bioseparation and olefin microspheres, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems of cumbersome operation, low sample activity recovery rate, and unsatisfactory purification effect, etc., and achieve high adsorption capacity and facilitate large-scale The effect of extraction and purification, convenient sample source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

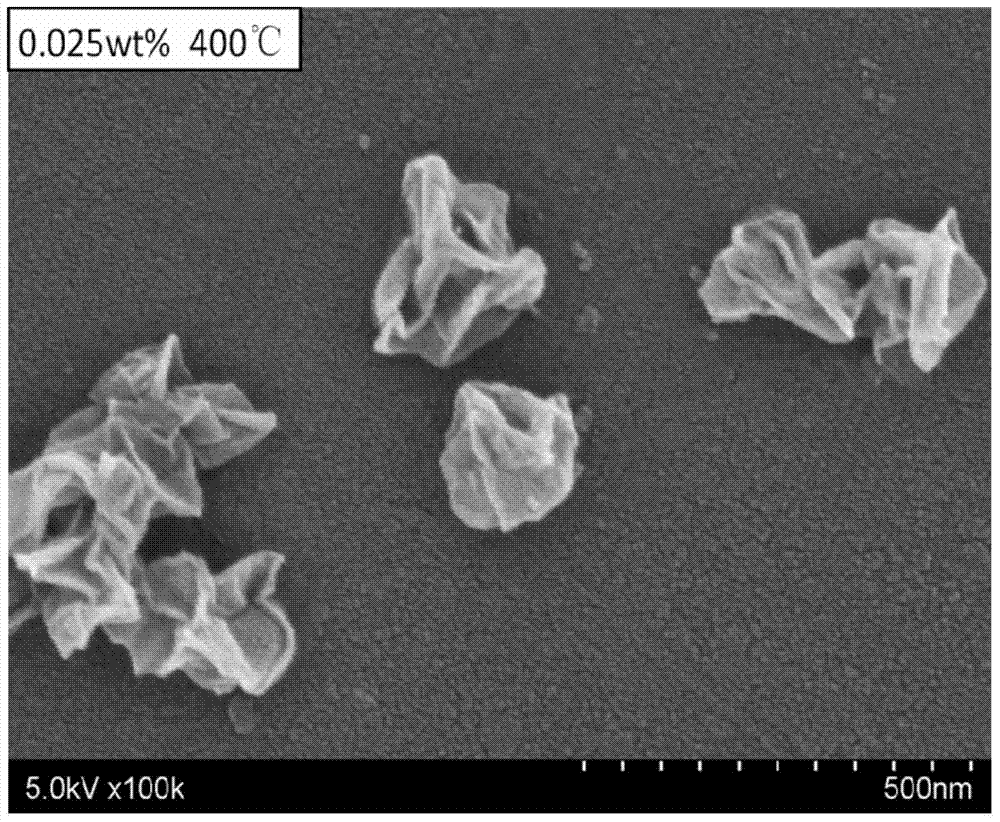

[0039] (1) Add graphene oxide (44.55% molar oxygen content) into deionized water to form a mixed solution, and the mass concentration of graphene oxide in the mixed solution is 0.025wt%. Stirring under a magnetic stirrer for 20 hours, the rotating speed is 1200r / min;

[0040] (2) Put the mixed solution into an ultrasonic machine, and after ultrasonic vibration for 10 hours, the graphene oxide flakes are sufficiently dispersed, cooled in ice water, and the temperature of the water in the ultrasonic machine is 20°C;

[0041] (3) The mixed solution is placed in the atomizer, and it is atomized into aerosol droplets. 2 Driven by a suction and filtration vacuum pump, it slowly passes through a quartz tube heated to 400°C, and the end is collected by a PTFE filter membrane with a pore size of 0.05um;

[0042] (4) The collected film was dried at room temperature for 6 hours, and then placed in a vacuum dryer at 60° C. for 24 hours to obtain graphene microspheres with a controllable ...

Embodiment 2

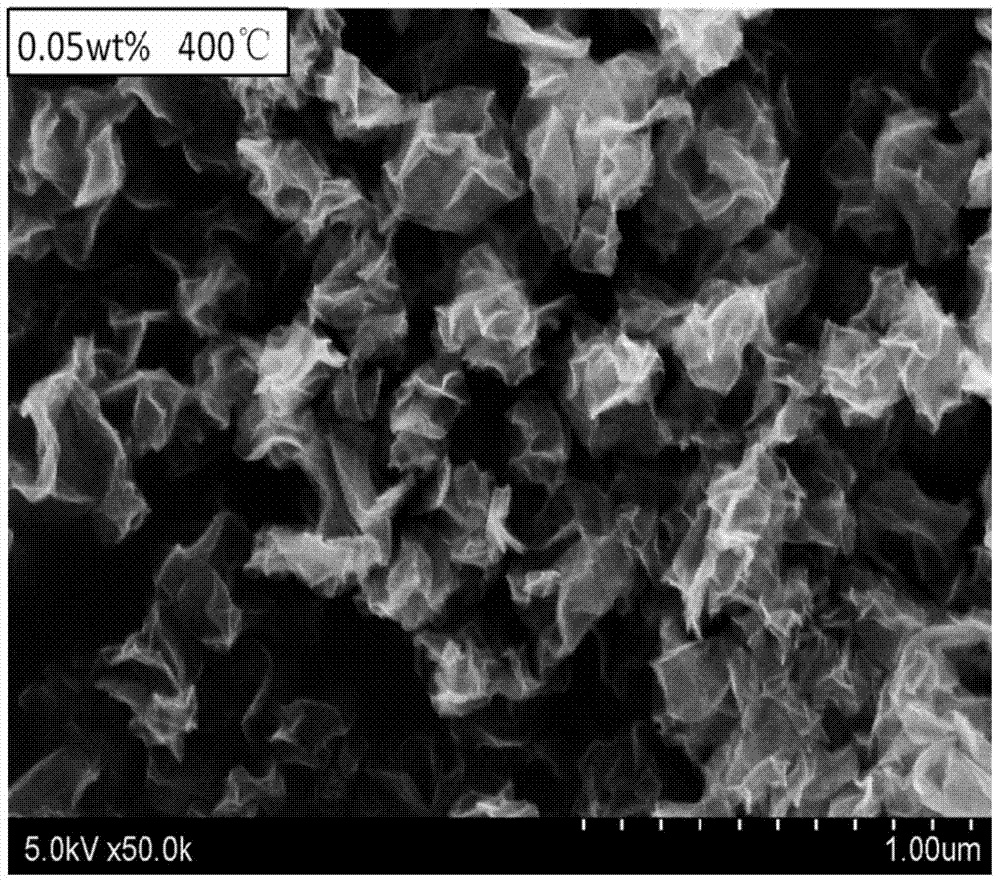

[0045] (1) Add graphene oxide (44.55% molar oxygen content) into deionized water to form a mixed solution, and the mass concentration of graphene oxide in the mixed solution is controlled to be 0.05wt%. Stirring under a magnetic stirrer for 20 hours, the rotating speed is 1200r / min;

[0046] (2) Put the mixed solution into an ultrasonic machine, and after ultrasonic vibration for 10 hours, the graphene oxide flakes are sufficiently dispersed, cooled in ice water, and the temperature of the water in the ultrasonic machine is 20°C;

[0047] (3) The mixed solution is placed in the atomizer, and it is atomized into aerosol droplets. 2 Driven by a vacuum pump and a suction filter, it slowly passes through a quartz tube heated to 400°C, and the end is collected with a 0.1um PTFE filter membrane;

[0048] (4) The collected film was dried at room temperature for 6 hours, and then placed in a vacuum dryer at 60° C. for 24 hours to obtain graphene microspheres with a controllable parti...

Embodiment 3

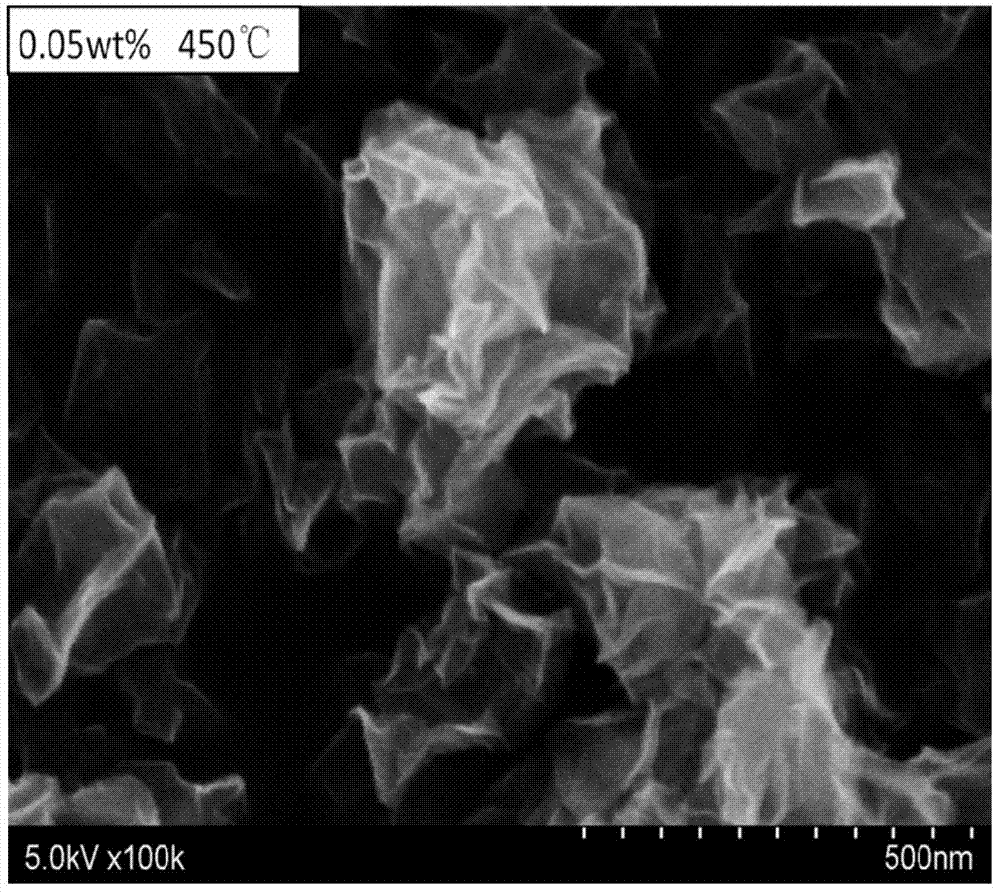

[0051] (1) Add graphene oxide (46.88% molar oxygen content) into deionized water to form a mixed solution, and the mass concentration of graphene oxide in the mixed solution is controlled to be 0.05wt%. Stirring under a magnetic stirrer for 20 hours, the rotating speed is 1200r / min;

[0052] (2) Put the mixed solution into an ultrasonic machine, and after ultrasonic vibration for 10 hours, the graphene oxide flakes are sufficiently dispersed, cooled in ice water, and the temperature of the water in the ultrasonic machine is 20°C;

[0053] (3) The mixed solution is placed in the atomizer, and it is atomized into aerosol droplets. 2 Driven by a vacuum pump and a suction filter, it slowly passes through a quartz tube heated to 450°C, and the end is collected with a 0.1um PTFE filter membrane;

[0054] (4) The collected film was dried at room temperature for 6 hours, and then placed in a vacuum dryer at 60° C. for 24 hours to obtain graphene microspheres with a controllable parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com