High-current live down lead component of overhead line and operating mechanism of high-current live down lead component

An operating mechanism and overhead line technology, applied in the direction of overhead line/cable equipment, line/collector parts, electrical components, etc., can solve the problems of not clamping the wire tightly, jamming, affecting power supply, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

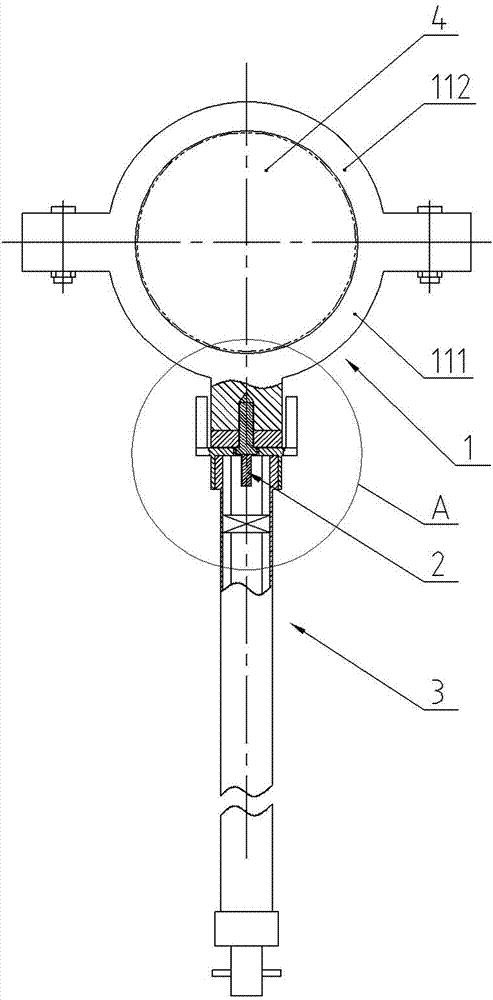

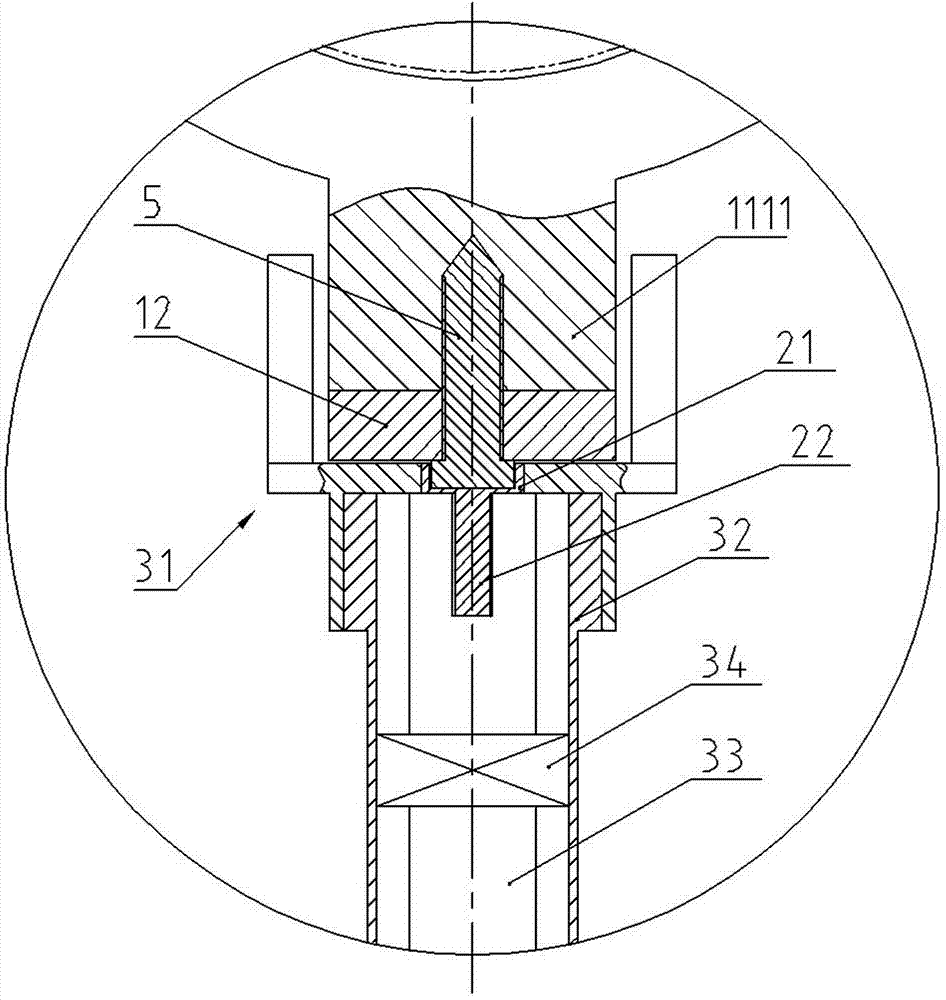

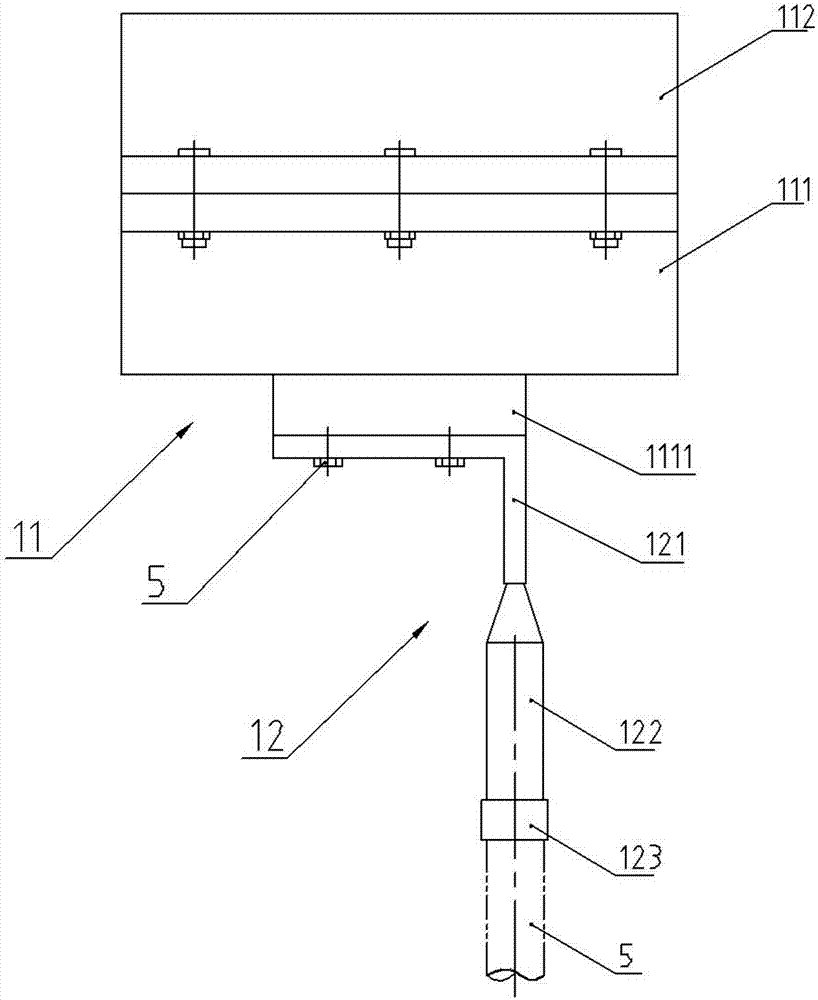

[0021] Such as Figure 1 to Figure 5 As shown, the present invention discloses a high-current live down-conductor component of an overhead line and its operating mechanism, including a down-conductor component 1 , a sleeve mold 2 and an operating mechanism 3 .

[0022] The down conductor member 1 includes a branch clamp 11 and a lug 12 . The branch wire clamp 11 has an upper and lower split structure, including a wire support plate 111 and a cover plate 112 that cooperate with each other. The middle section of the cross-section of the cover plate 112 and the thread support plate 111 is an outwardly protruding circular arc segment, and the two sides are connecting flanges. Butt holes are arranged on the connecting flange along the length direction, and the two circular arc segments cover the busbar 4. The cover plate 112 and the thread support plate 111 are connected and fastened by bolts passing through the butt holes and corresponding nuts. There is a protruding platform 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com