Multistage sweeping type silicon slice texturing and processing device and control method thereof

A technology of a processing device and a control method, which is applied in the manufacturing of final products, sustainable manufacturing/processing, discharge tubes, etc., can solve the problem that the damage removal layer and texturing of silicon wafers cannot be completed at one time, the on-line processing of industrial lines cannot be realized, and the drying process is hindered. Solving problems such as the industrialization process of etching method, to achieve the effect of fast and efficient silicon wafer processing, reducing adhesion by-products, and solving industrialization problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

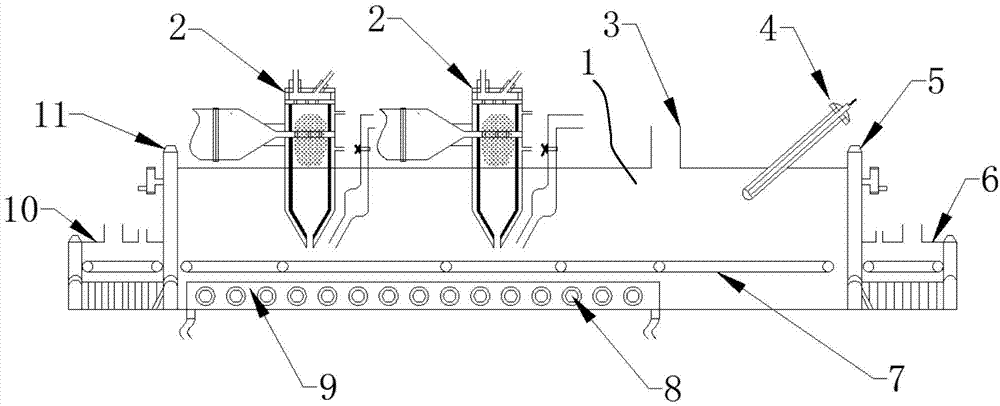

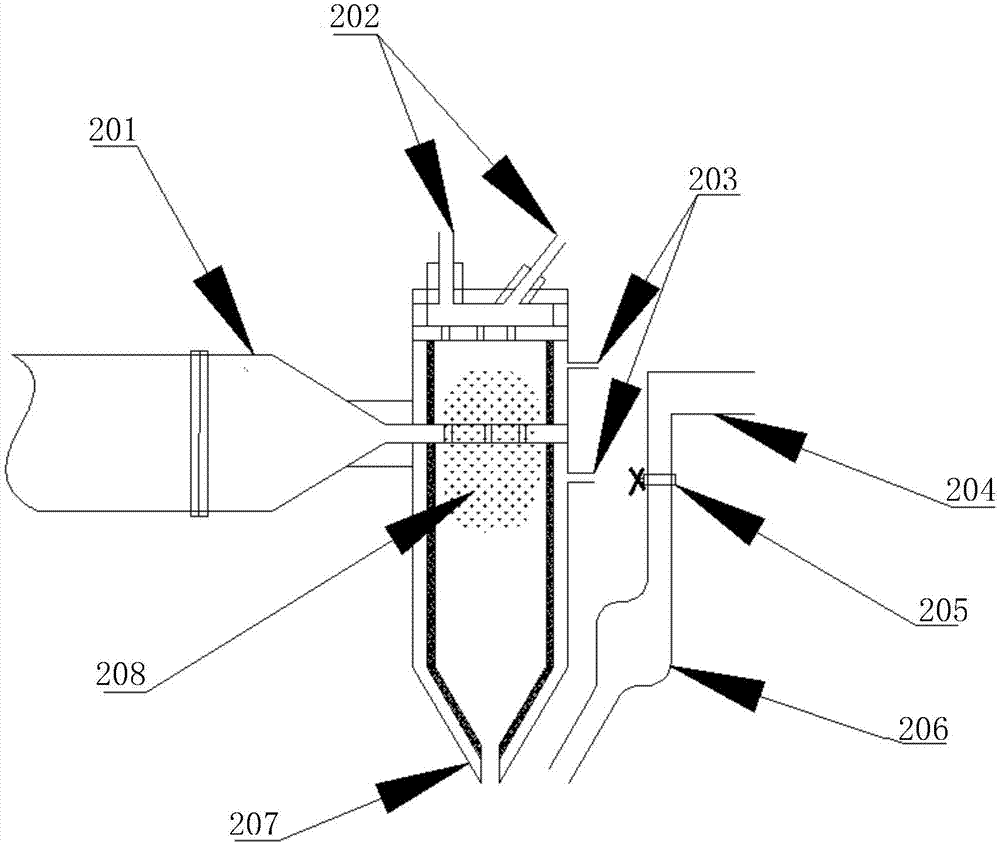

[0027] figure 1 It is a structural schematic diagram of the multi-stage purging type silicon wafer texturing treatment device of the present invention.

[0028] See figure 1 , the multi-stage purging type silicon wafer texture processing device provided by the present invention includes a reaction chamber 1, and a silicon wafer movement stage 7 is arranged in the reaction chamber 1, wherein, on the reaction chamber 1, at least There are two plasma downstream purging processing units 2, a front buffer chamber 10 and a front gate valve 11 are provided at the entrance of the reaction chamber 1, and a rear buffer chamber is provided at the exit of the reaction chamber 1. chamber 6 and rear gate valve 5, the reaction chamber 1 is provided with a reaction chamber vacuum outlet 3 near the rear buffer chamber 6, and a constant temperature radiation block 9 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com