Semiconductor device and manufacturing method thereof

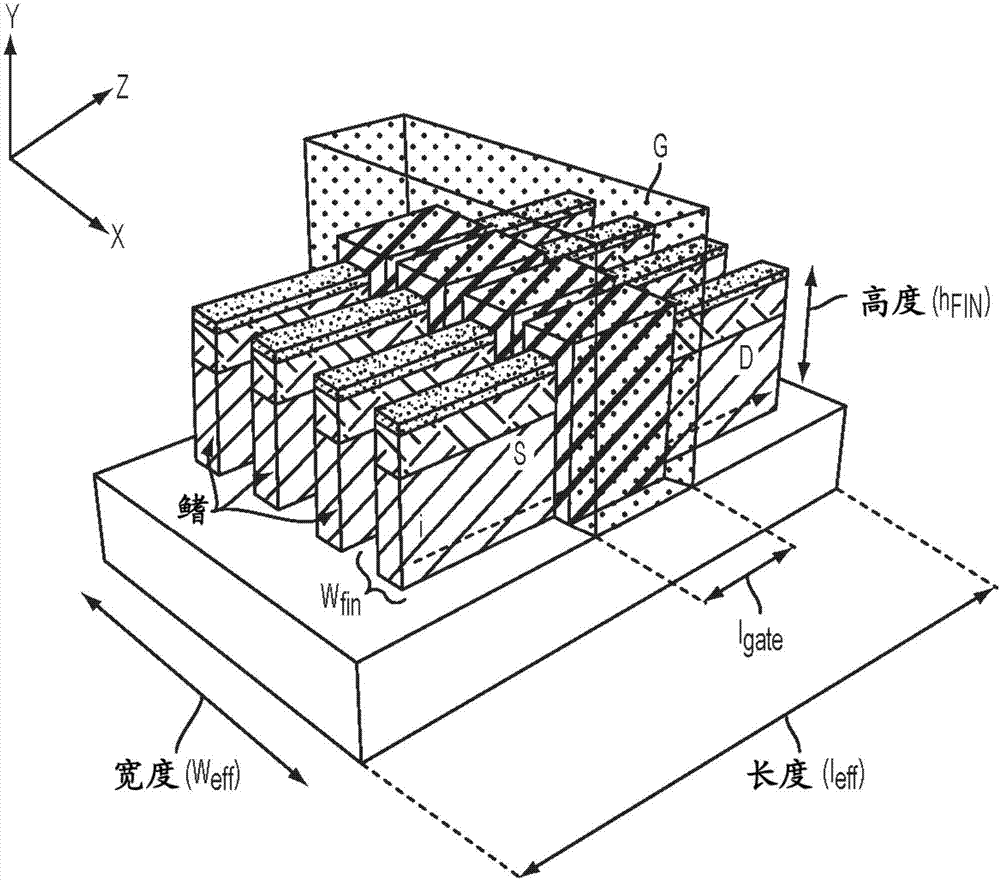

A semiconductor and device technology, applied in the field of FinFET semiconductor devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

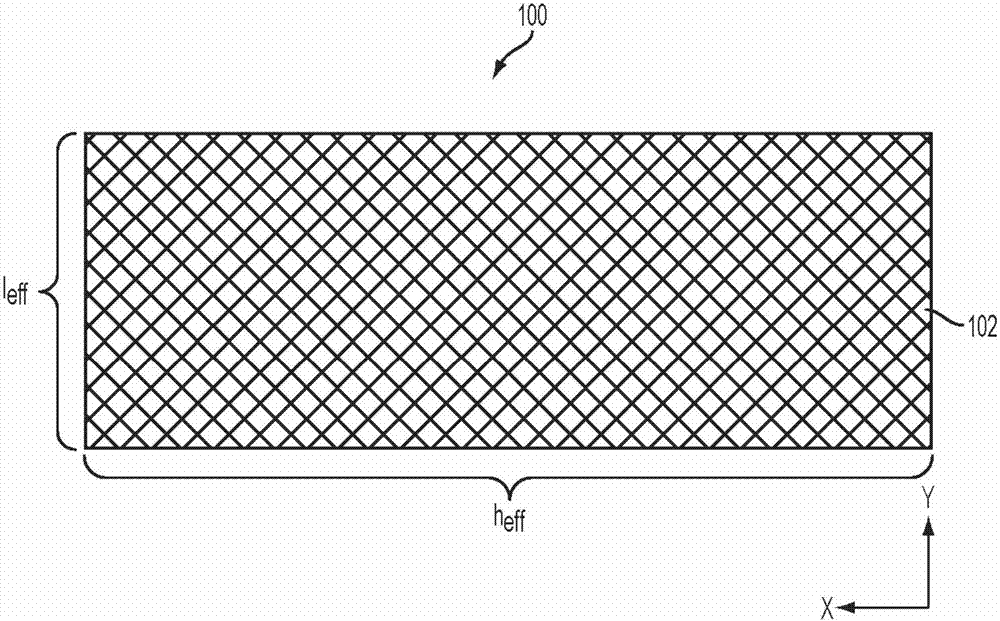

[0029] refer to figure 2 The semiconductor structure 100 includes a bulk semiconductor substrate 102 extending along an X-axis to define a height, and extending along a Y-axis perpendicular to the X-axis to define a length. The bulk semiconductor substrate 102 may be formed of a semiconductor material such as silicon (Si).

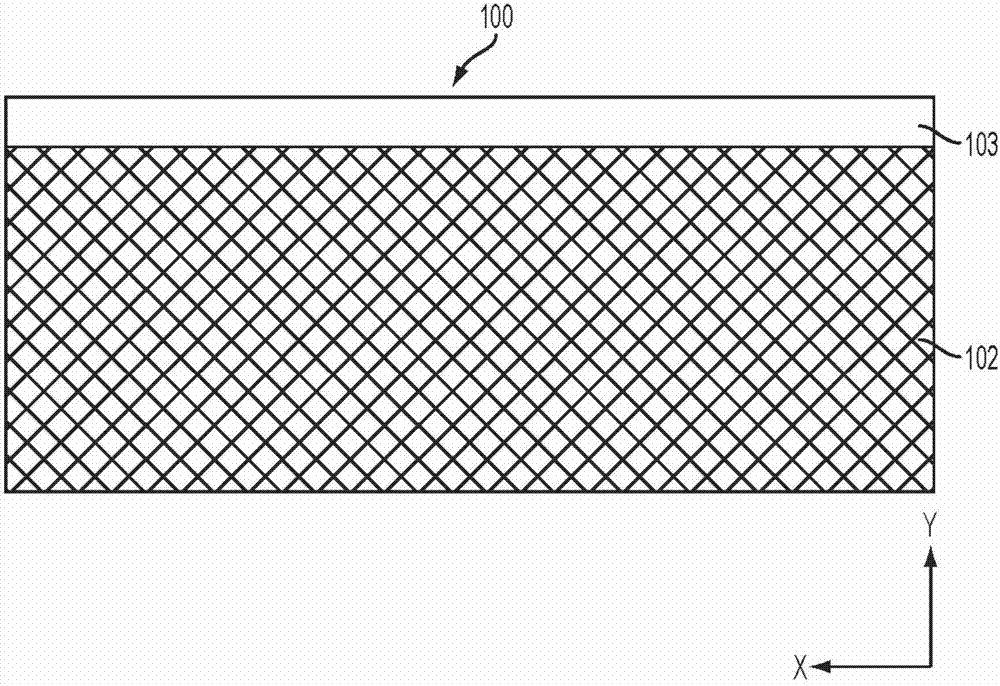

[0030] turn to image 3 , a hard mask layer 103 is formed on the upper surface of the bulk semiconductor substrate 102 . The hard mask layer 103 may be formed using chemical vapor deposition (CVD), and may be formed of a nitride mask material, as would be understood by those of ordinary skill in the art.

[0031] refer to Figure 4 , forming the core layer 104 on the upper surface of the hard mask layer 103 . The core layer 104 can be made of silicon oxide (SiO 2 ) CVD formation. Further, the core layer 104 may be formed of a material different in composition from the hard mask layer 103 to achieve etch selectivity. Materials for the core layer 104 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com