Traction transformer winding temperature rise and oil flow speed relevance testing method

A technology for the temperature rise of traction transformers and windings, which is applied in the direction of testing dielectric strength, etc., can solve problems such as increasing production costs, and achieve the effects of avoiding interference, improving measurement accuracy, and reducing monitoring costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

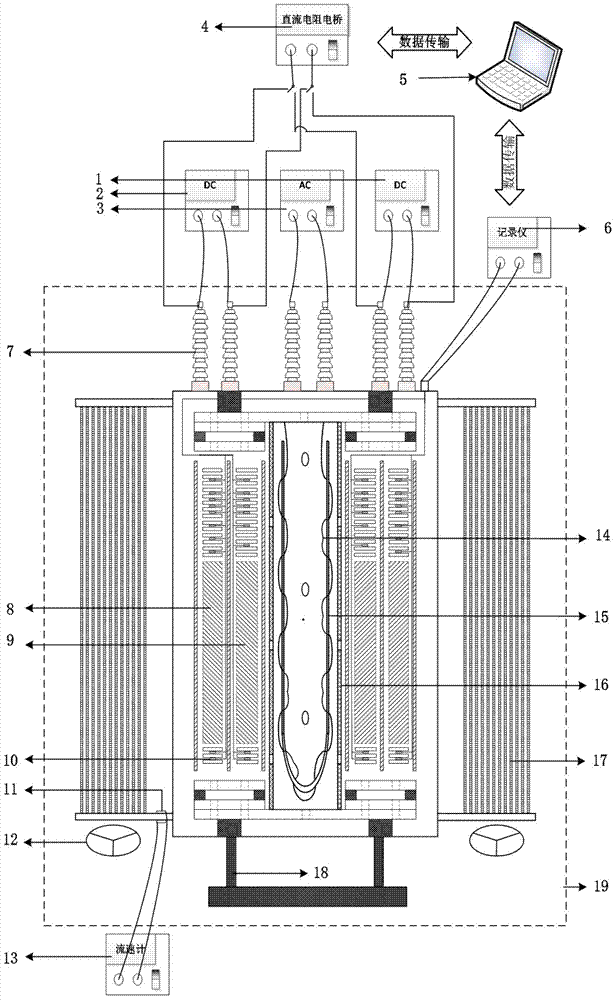

[0021] figure 1 Shown is the schematic diagram of the test system of the present invention. As shown in the figure, the system of the present invention includes: a first adjustable DC power supply 1, a second adjustable DC power supply 2, an adjustable AC power supply 3, a DC resistor 4, a computer 5, a paperless recorder 6, a temperature sensor 10, Flow rate sensor 11, fan 12, ultrasonic flowmeter 13, test transformer 19. The test transformer 19 is mainly composed of an insulator 7, a high voltage winding 8, a low voltage winding 9, a fan 12, a central resistance wire 14, a U-shaped insulating rod 15, an epoxy resin barrel 16, a radiator 17, a transformer shell and a supporting part 18. The center of the test transformer 19 is the iron core 0, and the central resistance wire 14 is wound on the U-shaped insulating rod 15 and placed in the epoxy resin bucket 16. Small holes are evenly punched around the epoxy resin bucket 16 (4 holes are punched on each circumference, 24 hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com