Universal sampler, gas chromatograph and hyphenated spectrometer

A sampler, general-purpose technology, applied in the field of analysis and detection, can solve the problems of not many, different gasification rates of different components, condensation and other problems, and achieve the effects of rapid heating and gasification, reducing split discrimination, and reducing heat capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

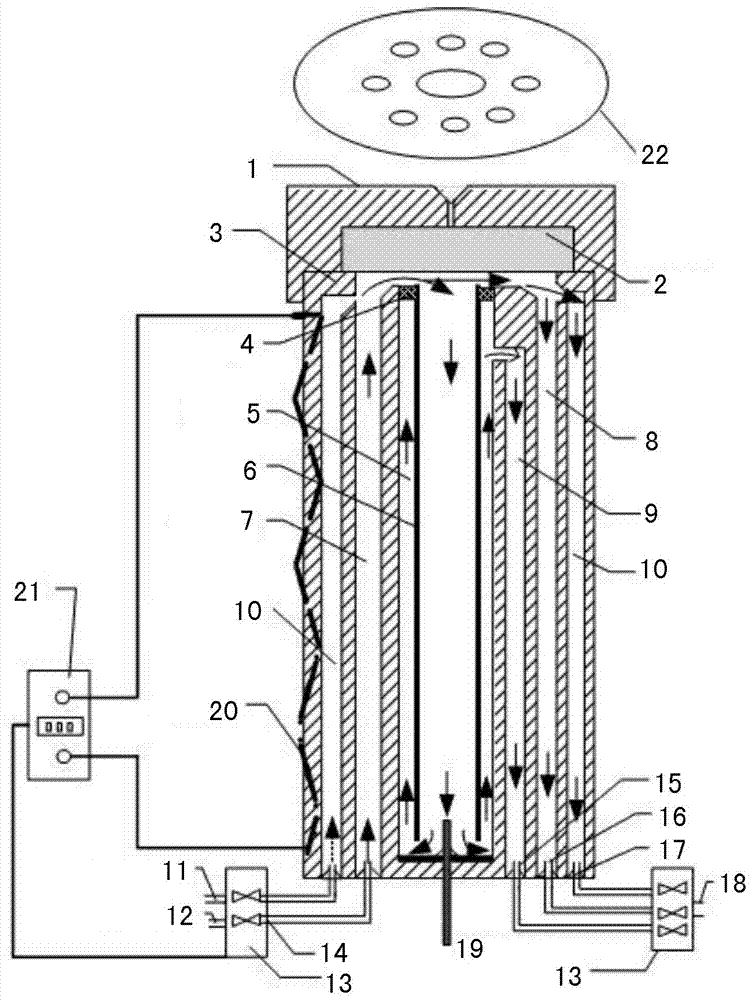

[0028] see figure 1, according to an embodiment of the present invention, the injection port mechanism of the injector is located on the top of the injector and consists of an end cap 1 and a septum 2 . The end cap 1 is sleeved on the sample injector housing 3 through a threaded buckle, which is easy to disassemble, and is convenient for inserting a disposable sample tube when injecting solid samples.

[0029] The gasification chamber 5 is located inside the sampler housing, and there is a sealing septum 2 between the gasification chamber 5 and the end cover 1 to seal the gasification chamber and the sampling port. The center of the gasification chamber is coaxial. A quartz or glass liner can be placed in the gasification chamber when gas or liquid samples are injected, and a disposable sample tube with adsorbed solid components can be placed when solid samples are injected.

[0030] The liner or disposable sample tube 6 is tightly sealed by an O-ring 4 and supported in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com