Two-stage coal gas generating device

A technology for a gas generator and coal bunker, which is applied in the manufacture of combustible gas, climate sustainability, petroleum industry, etc. The effect of stable gas output, gas quality and improving gas output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

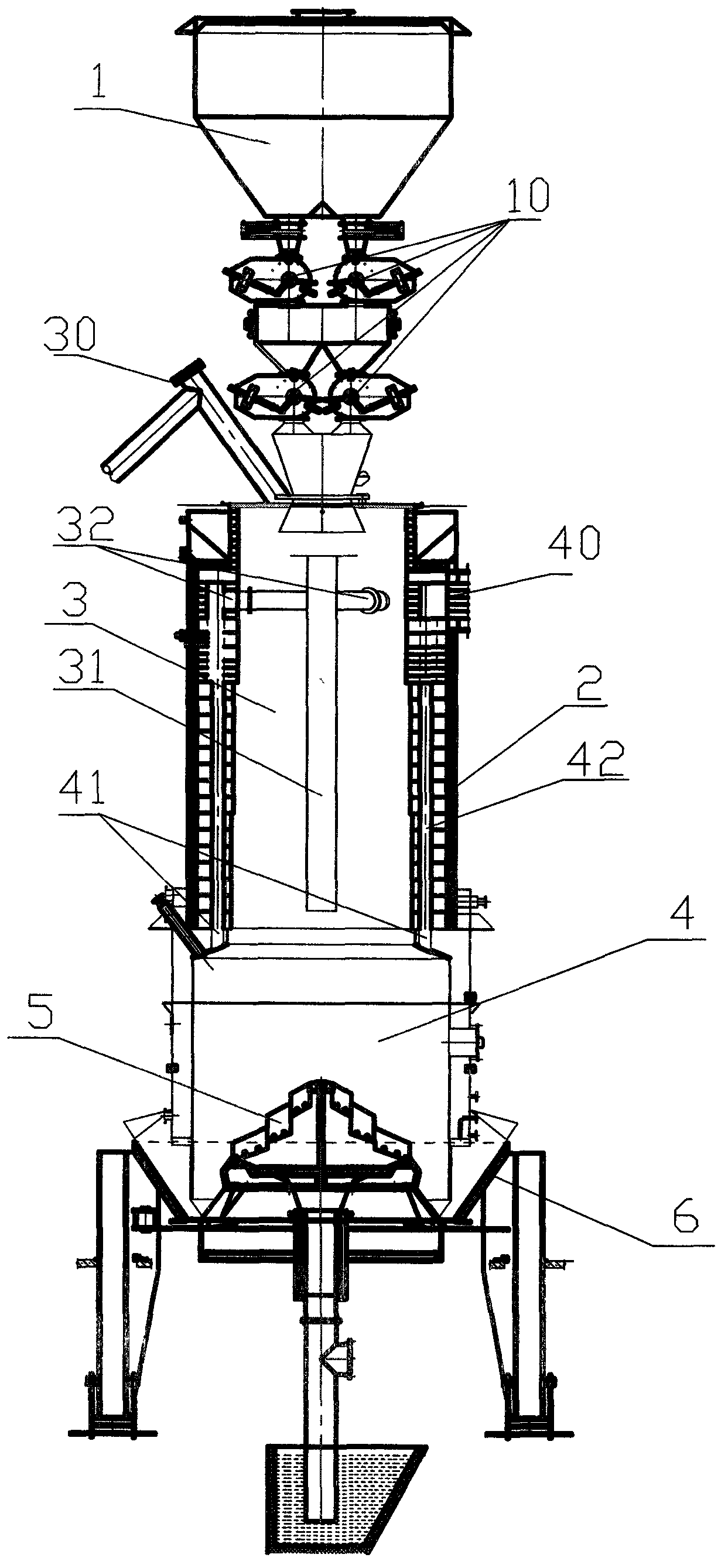

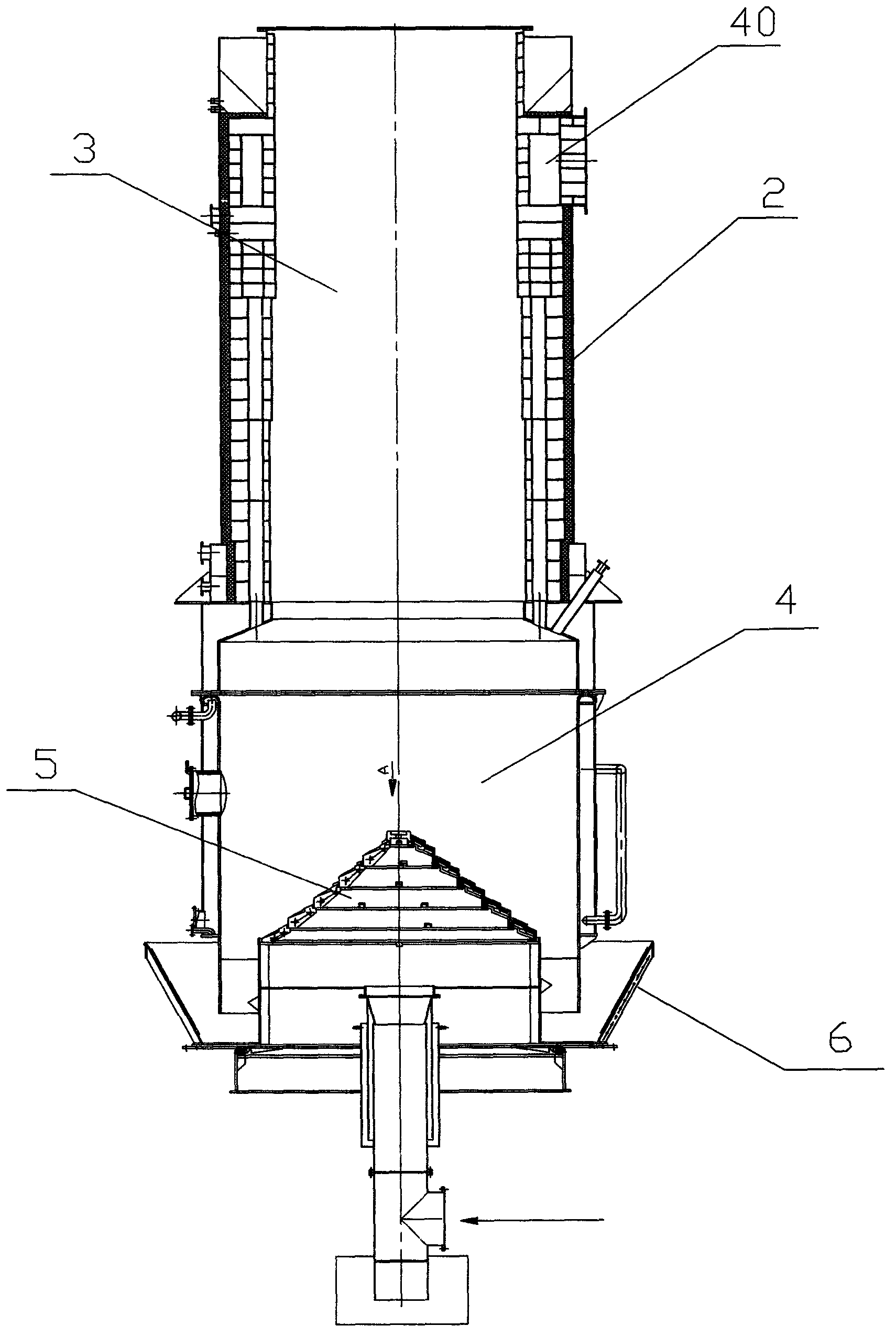

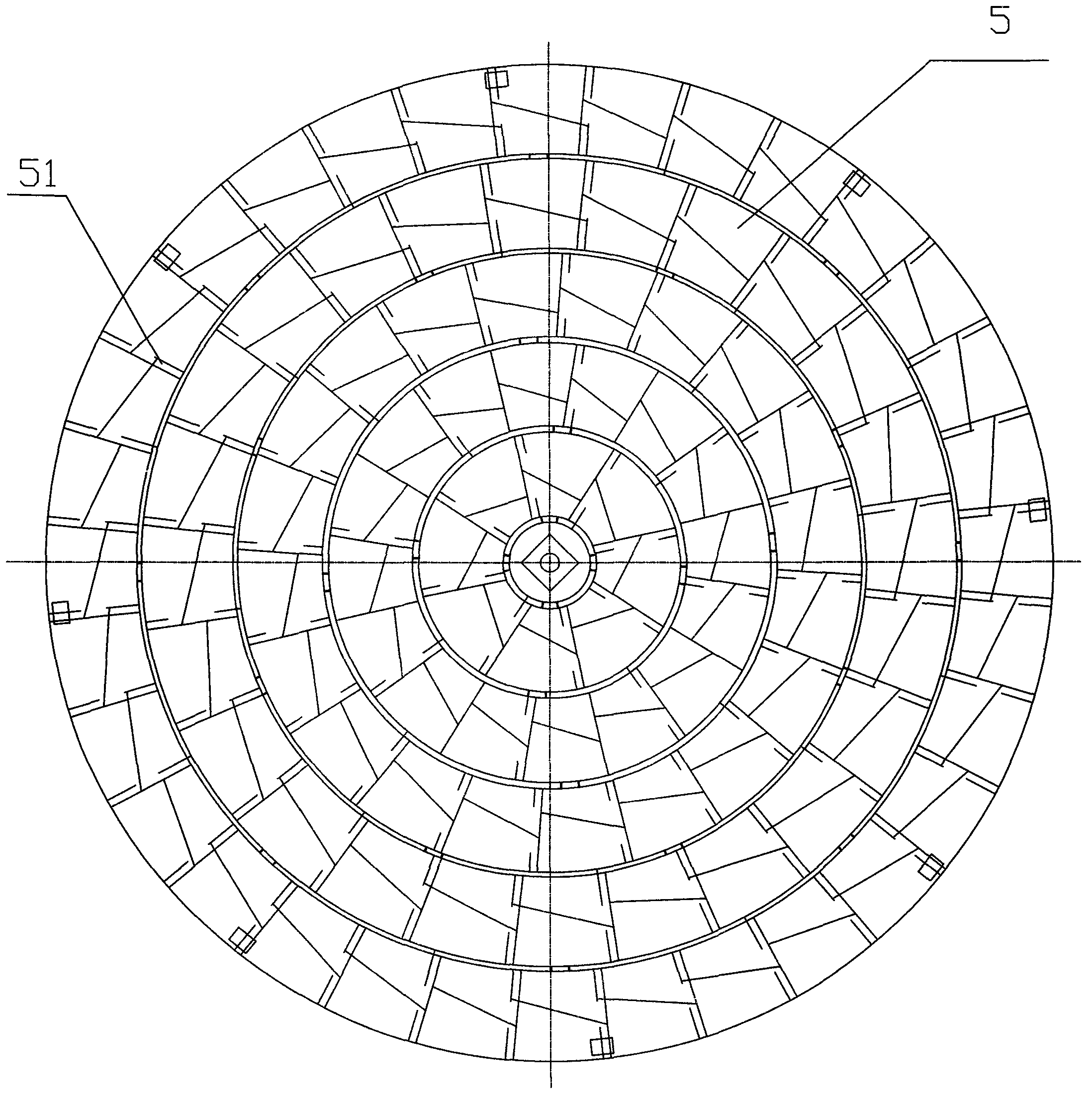

[0019] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , a two-stage gas generating device, comprising a coal bunker 1 and a furnace body 2 composed of a retort section 3, a gasification section 4, a grate 5 and an ash discharge device 6, and a gas outlet pipe 30 is arranged on the top of the retort section 3 Lead out the carbonization low-temperature high-calorific value gas in the upper stage, and a center pipe 31 is arranged at the center of the carbonization section 3, and the center pipe 31 is used to collect the lower-stage high-temperature gas produced in the reaction layer. Since the center pipe 31 is arranged in the center of the carbonization section 3, The high-temperature gas collected in the lower section of the central tube 31 can dry and dry the coal around the central tube 31 during the transportation process, and it is a thermal processing radiated from the center to the periphery, so as to avoid uneven heating and dry distilla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com