Preparation process of high hardness stainless steel

A preparation process, stainless steel technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of blurred car lines, affecting appearance requirements, etc., to prevent uneven hardness and white brightness , uniform gasification, and the effect of improving surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

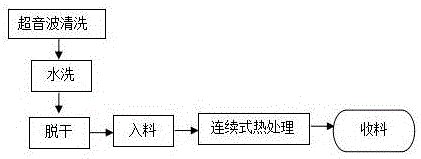

[0024] A preparation process of high-hardness stainless steel comprises the following specific steps:

[0025] Step 1): Warm the cleaning water to 70°C, add a water-soluble degreasing agent to the water, the amount of the water-soluble degreasing agent is 50ML / L, put the stainless steel material into the aqueous solution, and clean it with ultrasonic vibration for 10 minutes. The sonic oscillation frequency is 48HZ;

[0026] Step 2): Remove the surface film of the stainless steel material obtained in step 1) in cleaning equipment equipped with 8% hydrochloric acid for 2 minutes, and the frequency of pulling the net is 10 / minute, and then wash the overflow with water again;

[0027] Step 3): Place the stainless steel material obtained in step 2) in a heating dehydrator, dehydrate for 5 minutes, set the temperature at 80°C for 1 minute, and pull the mesh at a frequency of 8 / time;

[0028] Step 4): Put the cleaned stainless steel material into the self-made baking tray and sprea...

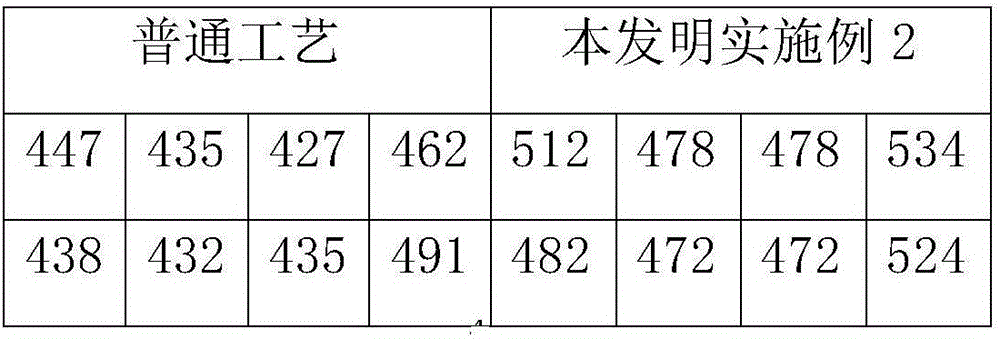

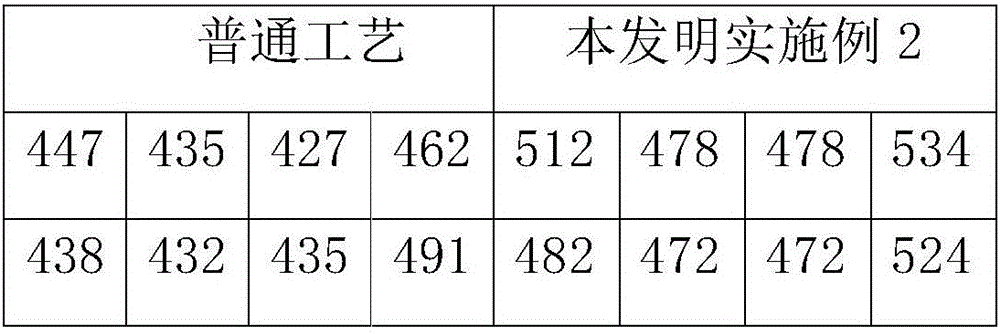

Embodiment 2

[0032] A preparation process of high-hardness stainless steel comprises the following specific steps:

[0033] Step 1): Warm the cleaning water to 73°C, add a water-soluble degreasing agent to the water, the amount of the water-soluble degreasing agent is 65ML / L, put the stainless steel material into the aqueous solution, and clean it with ultrasonic vibration for 12 minutes. The sonic oscillation frequency is 48HZ;

[0034] Step 2): Remove the surface film of the stainless steel material obtained in step 1) in a cleaning device equipped with 8% hydrochloric acid for 4 minutes, and the frequency of pulling the net is 10 / minute, and then wash the overflow with water again;

[0035] Step 3): Place the stainless steel material obtained in step 2) in a heating dehydrator, dehydrate for 5 minutes, set the temperature at 80°C for 2 minutes, and pull the mesh at a frequency of 8 / time;

[0036] Step 4): Put the cleaned stainless steel material into the self-made baking tray and sprea...

Embodiment 3

[0040] A preparation process of high-hardness stainless steel comprises the following specific steps:

[0041] Step 1): Warm the cleaning water to 75°C, add a water-soluble degreasing agent to the water, the amount of the water-soluble degreasing agent is 80ML / L, put the stainless steel material into the aqueous solution, and clean it with ultrasonic vibration for 15 minutes. The sonic oscillation frequency is 48HZ;

[0042] Step 2): Remove the surface film of the stainless steel material obtained in step 1) in cleaning equipment equipped with 8% hydrochloric acid for 5 minutes, and the frequency of pulling the net is 10 / minute, and then wash the overflow with water again;

[0043] Step 3): Place the stainless steel material obtained in step 2) in a heating dehydrator, dehydrate for 5 minutes, set the temperature at 80°C for 2 minutes, and pull the mesh at a frequency of 8 / time;

[0044] Step 4): Put the cleaned stainless steel material into the homemade baking tray and sprea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com