Co-extrusion polymer composite wear-resisting floor and preparation method thereof

A composite material, wear-resistant floor technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of poor wear resistance, poor aging resistance, affecting service life, etc. performance and aging resistance, reduce product cost, and control the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

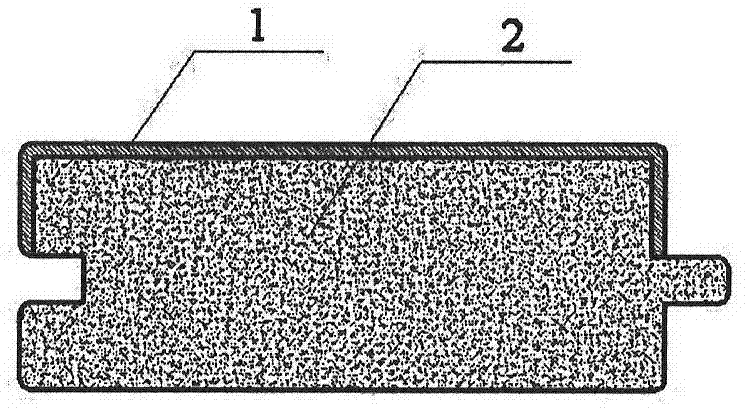

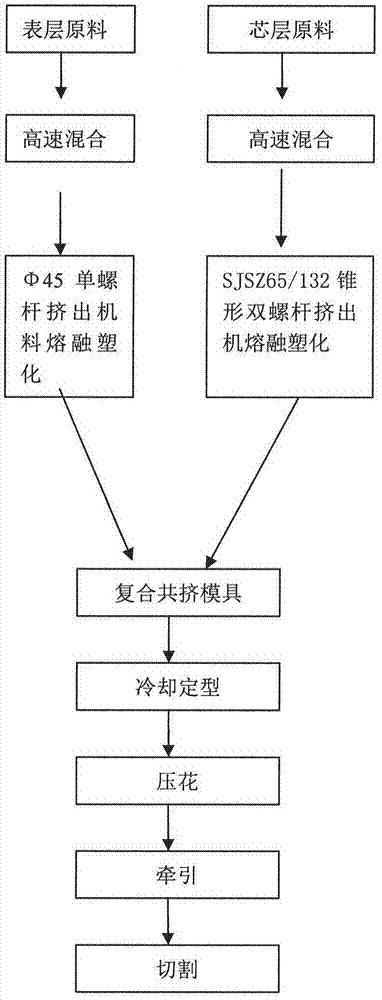

[0024] According to the wear-resistant floor of the co-extruded polymer composite material of the present invention, the surface layer 1 includes the following materials in weight percentage: 95% of ultra-high molecular weight polyethylene powder with a viscosity-average molecular weight of 1.50-4.5 million, 1% of polyethylene wax, iron oxide Palm 4%; core layer 2 includes the following materials in weight percentage: waste polyethylene 40%, wood powder 6%, fly ash 45%, ultrafine activated calcium carbonate 6%, azodicarbonamide 0.7%, DCP0.3 %, Zn01%, polyethylene wax 1%.

[0025] The preparation method is as follows:

[0026] (1) Weigh the surface layer raw materials in proportion and add them to the high-speed mixer. After high-speed mixing for 7-10 minutes, they are discharged into the surface layer storage bin, and automatically loaded to the Φ45 type ultra-high molecular weight polyethylene for surface layer processing by the spring feeder. In the hopper of a special sing...

Embodiment 2

[0032] According to the wear-resistant floor of the co-extruded polymer composite material of the present invention, the surface layer 1 includes the following materials in weight percentage: 95% of ultra-high molecular weight polyethylene powder with a viscosity-average molecular weight of 3 to 4 million, 2% of polyethylene wax, iron oxide Palm 3%; core layer 2 includes the following materials in weight percentage: waste polypropylene 40%, wood flour 10%, fly ash 40%, superfine activated calcium carbonate 5%, azodicarbonamide 0.6%, DCP0.4 %, Zn02%, polyethylene wax 2%.

[0033] The preparation method is as follows:

[0034] (1) Weigh the surface layer raw materials in proportion and add them to the high-speed mixer. After high-speed mixing for 7-10 minutes, they are discharged into the surface layer storage bin, and automatically loaded to the Φ45 type ultra-high molecular weight polyethylene for surface layer processing by the spring feeder. In the hopper of a special singl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com